Horizontal buried pipe system

A buried pipe, horizontal technology, applied in the field of horizontal buried pipe system, can solve the problems of heat pump unit performance degradation, easy damage to the separation bracket, uneconomical heat pump, etc., achieve simple structure, solve large footprint, The effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

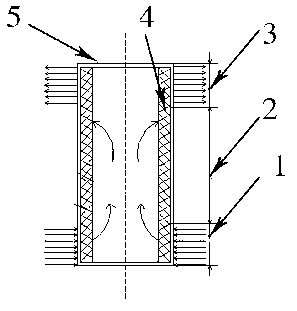

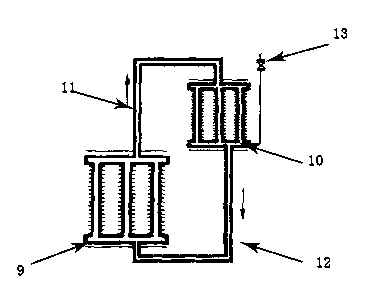

Method used

Image

Examples

Embodiment

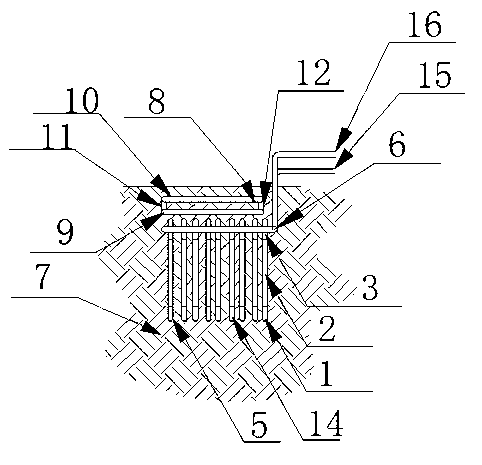

[0018] Example: such as image 3 As shown, the working temperature required for the buried pipe should be determined before installation, and the matching working fluid should be selected. In this embodiment, the working medium of the gravity heat pipe is selected as ethanol, and the condensation temperature of the gravity heat pipe, that is, the working temperature of the heat pipe, is determined according to the working temperature of the buried pipe. The working fluid of the separated heat pipe is selected as methanol, and the evaporation temperature of the separated heat pipe is determined according to the working temperature of the buried pipe. The length of the gravity heat pipe is 3 meters, and the heat exchange area of the separated heat pipe covers the whole buried pipe area.

[0019] When installing, first dig the pipe trench for laying the horizontal underground pipe, and drive the vacuumed gravity heat pipe 14 vertically into the ground. The bottom of the pipe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com