Manufacturing method of enthalpy wheel humidifier

A manufacturing method, humidifier technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrochemical generators, etc., can solve the problems affecting the life of the humidifier, high friction resistance, reducing oxygen concentration, etc., to achieve replacement High wet heat transfer efficiency, simple manufacturing method, and the effect of ensuring oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

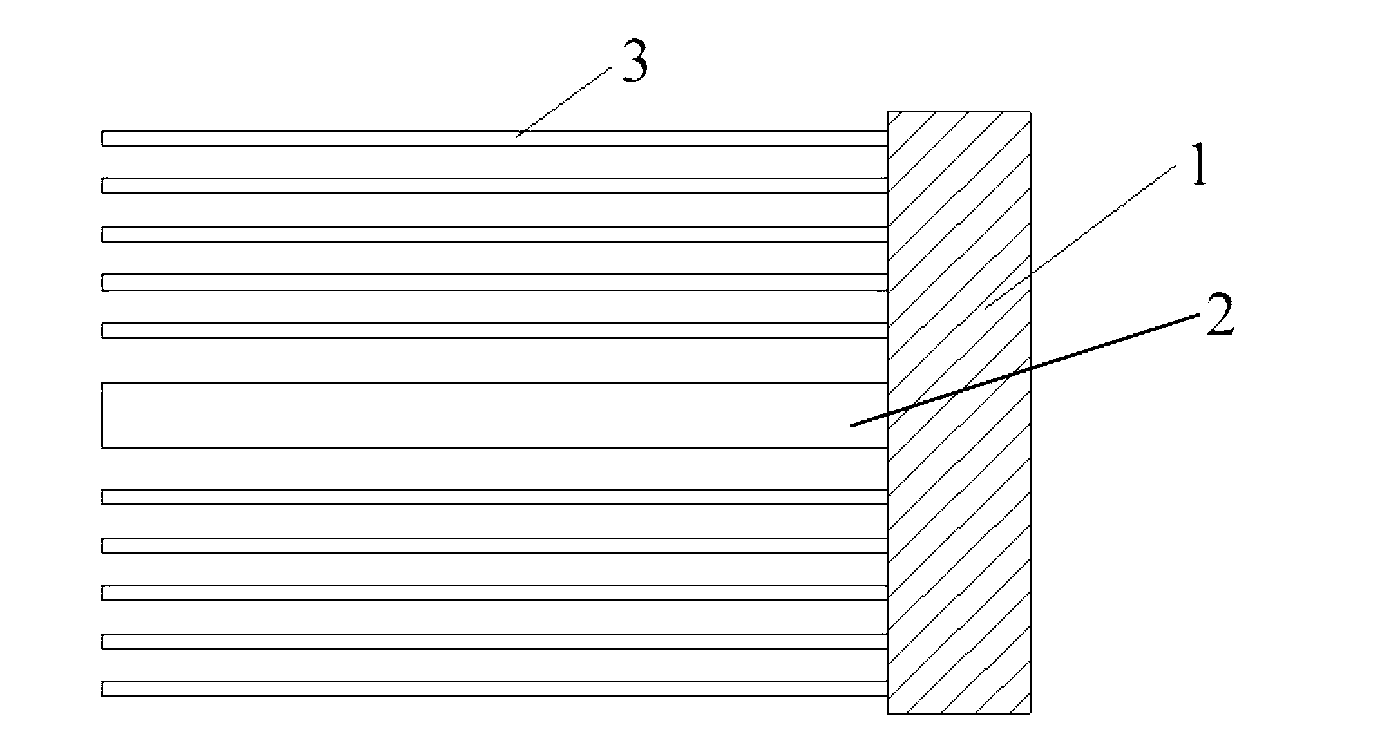

[0055] 1) Ingredients: According to the actual size of the enthalpy wheel in the enthalpy wheel humidifier, weigh various substances used. Based on the weight of the enthalpy wheel in the enthalpy wheel humidifier, weigh 4wt% aramid, 74wt% 5123 type phenolic resin, 7wt% urotropine and 15wt% ammonium bicarbonate.

[0056]2) Mixing: Put the weighed substances into a high-speed mixer, stir at a high speed to make the mixture even, and the stirring time is 1 minute.

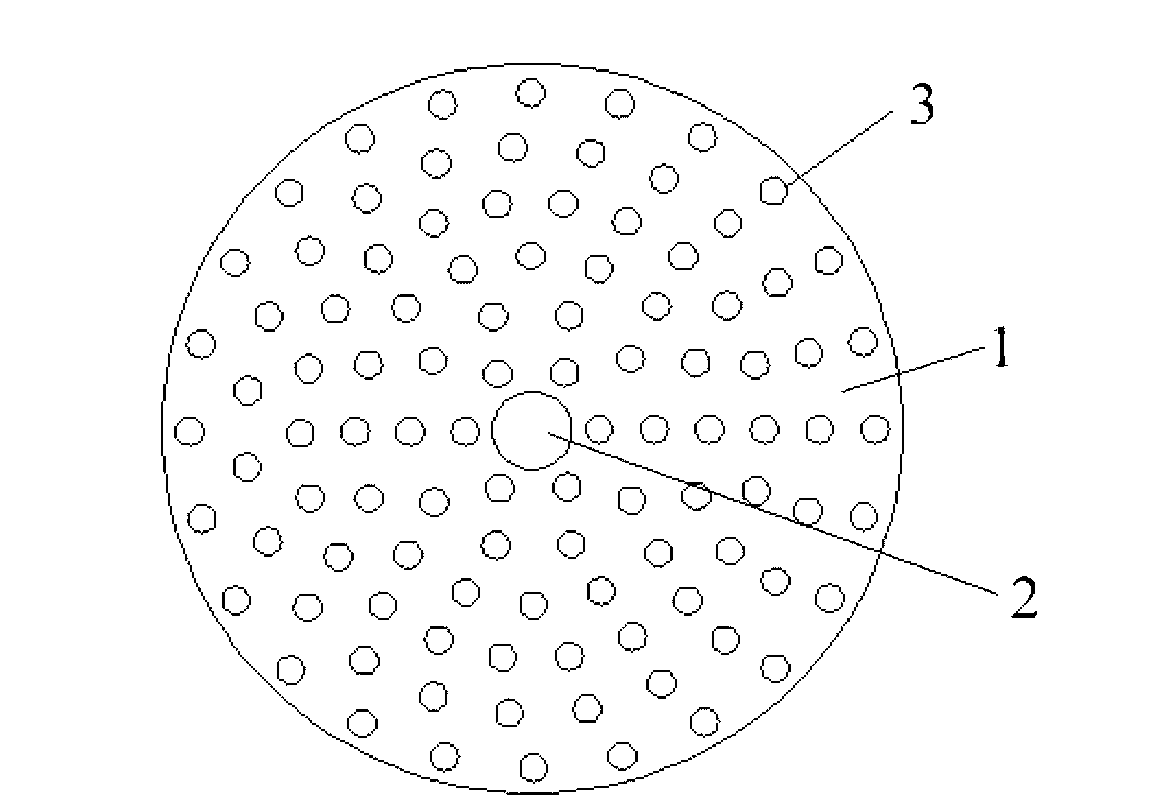

[0057] 3) Heat treatment molding: put the mixture obtained after high-speed stirring into the mold and perform heat curing treatment. The heating temperature is set at 180°C, and the heating time is set at 60 minutes, then cooled and demoulded, and the obtained enthalpy wheel It is a porous honeycomb cylinder, and the through holes with a diameter of 5-10mm are uniformly distributed along the axial direction.

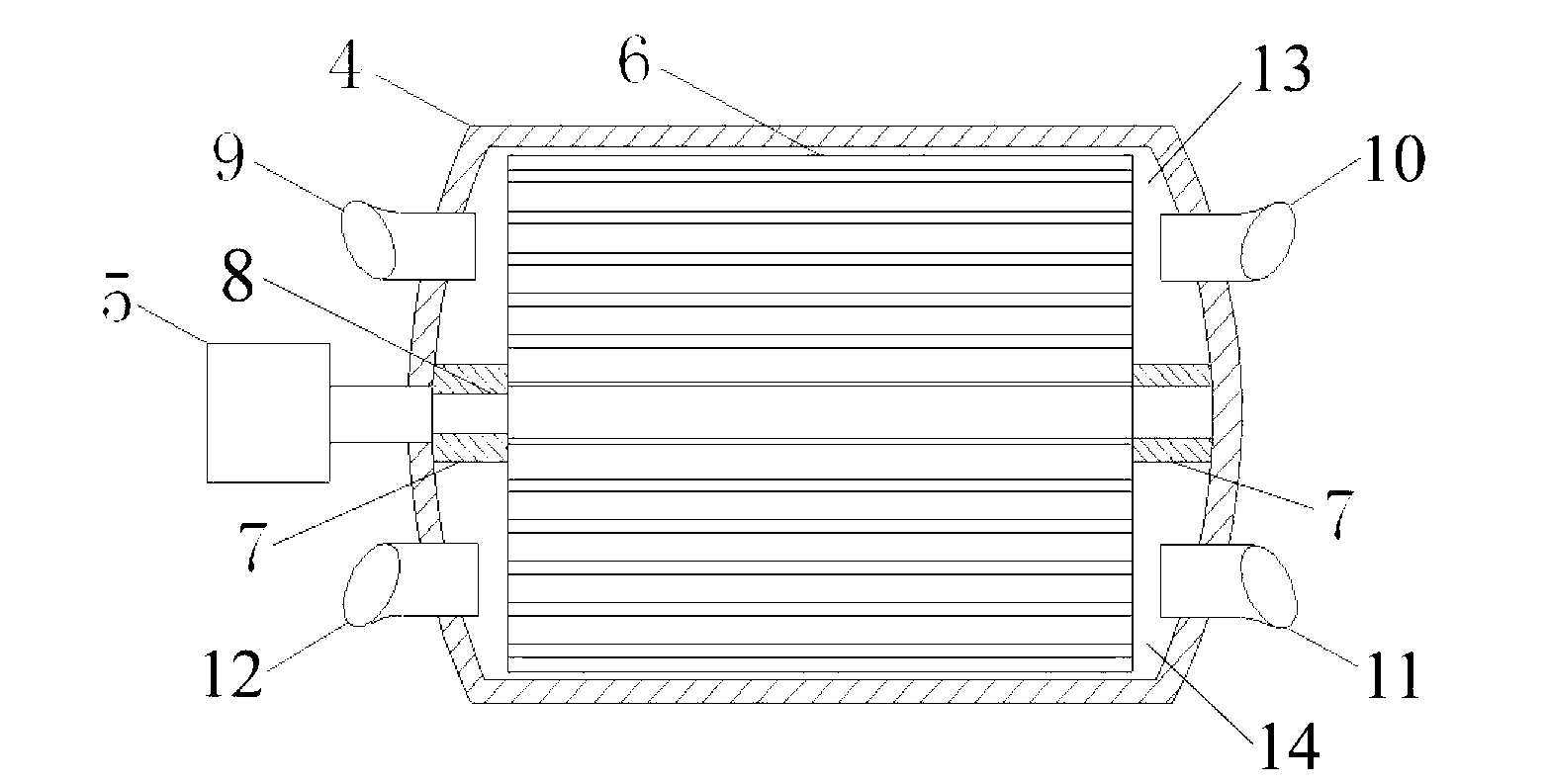

[0058] 4) Assembly: Put the enthalpy wheel into the cylindrical shell, the center of the enthalpy wheel sh...

Embodiment 2

[0061] 1) Ingredients: According to the actual size of the enthalpy wheel in the enthalpy wheel humidifier, weigh various substances used. Based on the weight of the enthalpy wheel in the enthalpy wheel humidifier, weigh 3wt% aramid fiber, 65wt% 5123 type phenolic resin, 6wt% urotropine and 26wt% ammonium bicarbonate.

[0062] 2) Mixing: Put the weighed substances into a high-speed mixer, stir at a high speed to make the mixture even, and the stirring time is 1 minute.

[0063] 3) Heat treatment molding: put the mixture obtained after high-speed stirring into the mold and perform heat curing treatment. The heating temperature is set at 180°C, and the heating time is set at 60 minutes, then cooled and demoulded, and the obtained enthalpy wheel It is a porous honeycomb cylinder, and the through holes with a diameter of 5-10mm are uniformly distributed along the axial direction.

[0064] 4) Assembly: Put the enthalpy wheel into the cylindrical shell, the center of the enthalpy w...

Embodiment 3

[0067] 1) Ingredients: According to the actual size of the enthalpy wheel in the enthalpy wheel humidifier, weigh various substances used. Based on the weight of the enthalpy wheel in the enthalpy wheel humidifier, weigh 3wt% aramid fiber, 57wt% 5123 type phenolic resin, 6wt% urotropine and 34wt% ammonium bicarbonate.

[0068] 2) Mixing: Put the weighed substances into a high-speed mixer, stir at a high speed to make the mixture even, and the stirring time is 1 minute.

[0069] 3) Heat treatment molding: put the mixture obtained after high-speed stirring into the mold and perform heat curing treatment. The heating temperature is set at 180°C, and the heating time is set at 60 minutes, then cooled and demoulded, and the obtained enthalpy wheel It is a porous honeycomb cylinder, and the through holes with a diameter of 5-10mm are uniformly distributed along the axial direction.

[0070] 4) Assembly: Put the enthalpy wheel into the cylindrical shell, the center of the enthalpy w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com