Combined pretreatment method for industrial wastewater

A technology for industrial wastewater and pretreatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve industrial wastewater with complex components, high concentration and toxicity, high treatment cost, etc. problem, to achieve the effect of water erosion resistance, good effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with specific embodiment, further set forth the present invention:

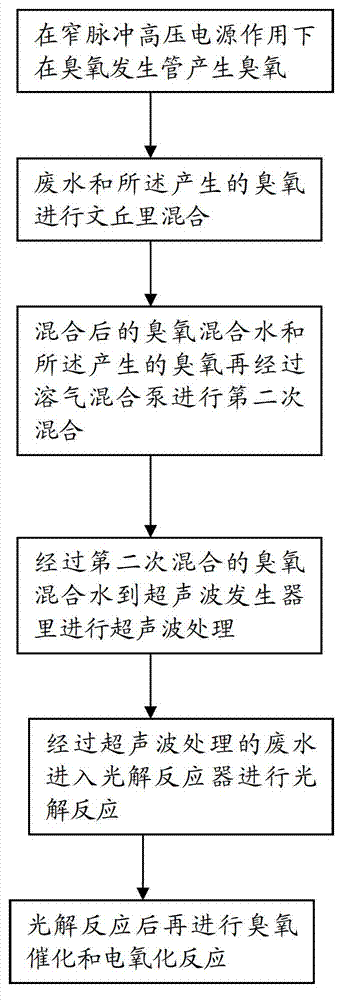

[0033] like figure 1 Shown, a kind of industrial wastewater combined pretreatment method comprises the following steps:

[0034] 1) Ozone is generated in the ozone generating tube under the action of a narrow pulse high-voltage power supply;

[0035] 2) Venturi mixing of wastewater and the generated ozone;

[0036] 3) The mixed ozone mixed water and the generated ozone are mixed for the second time through the dissolved air mixing pump;

[0037] 4) After the second mixing, the ozone mixed water is sent to the ultrasonic generator for ultrasonic treatment;

[0038] 5) The ultrasonically treated wastewater enters the photolysis reactor for photolysis reaction;

[0039] 6) After the photolysis reaction, ozone catalysis and electro-oxidation reaction are carried out.

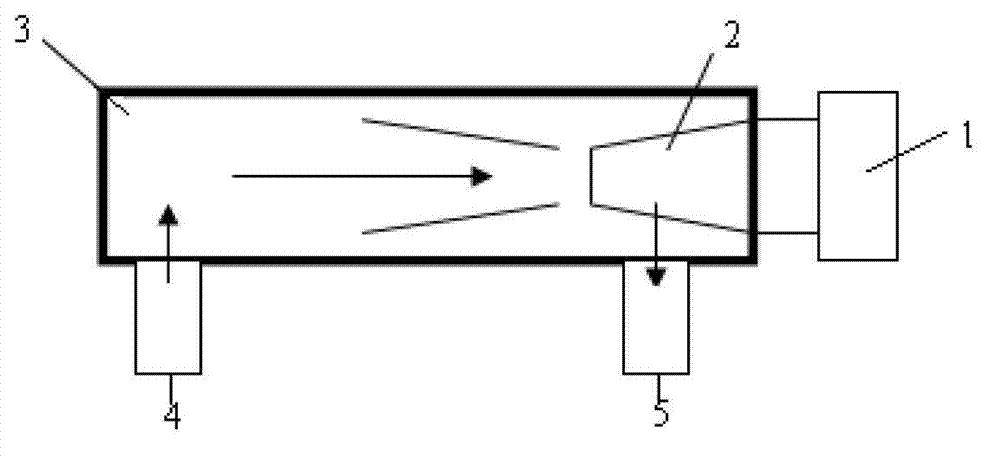

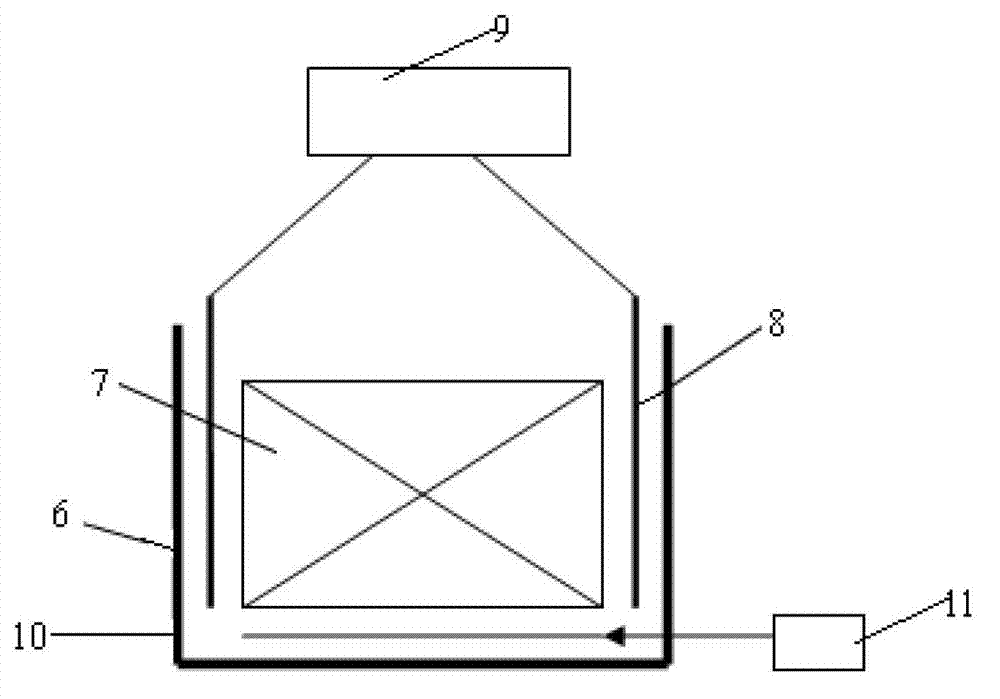

[0040] The ultrasonic generator of the present invention is a focused ultrasonic generator 1; a catalyst 7 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com