Preparation technology of light stabilizer

A manufacturing process and light stabilizer technology, applied in organic chemistry and other fields, can solve the problems of difficult control of synthesis and violent reaction, and achieve good light stabilization effect and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

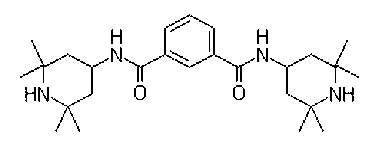

Image

Examples

Embodiment 1

[0013] Preparation:

[0014] In a 2000ml four-neck flask equipped with a condenser, a reflux tube, a thermometer, and an agitator, add quantitatively 150g of 2,2,6,6-tetramethyl-4-piperidinamine as the main ingredient, and a mass concentration of 100g The mass concentration of 30% liquid caustic soda, 50g is 50% ethanol aqueous solution, puts into the synthesis kettle, starts the stirrer, rotates after 30 minutes with 78 revolutions per minute, mixes 102g isophthaloyl chloride with 5 grams per minute and drops Addition to the above mixed solution, at the same time, start to cool the reactor to 30-35°C, keep warm at 30-35°C for 1 hour, and the sampling test is qualified; raise the temperature to 80°C, separate the lower layer of water, and then use molecular distillation on the upper layer (The vacuum reaches below 50Pa, and the temperature is 100°C; the distillation temperature under normal pressure reaches 250°C). Without crystallization, qualified products can be obtained, ...

Embodiment 2

[0016] Preparation:

[0017] In a 2000ml four-neck flask equipped with a condenser, a reflux tube, a thermometer, and an agitator, quantitatively add 160g of 2,2,6,6-tetramethyl-4-piperidinamine, and a mass concentration of 100g of 30 The mass concentration of % liquid caustic soda, 50g is 50% ethanol aqueous solution, drops into in the synthesis kettle, starts agitator, after turning 30 minutes with 78 revolutions per minute, with 102 grams of isophthaloyl chlorides with the speed of 5 gram minutes / drops Add to the above mixed solution by mixing and dropping method, and at the same time start to cool the reactor to 30-35°C, keep warm at 30-35°C for 1 hour, and the sampling test is qualified; the temperature is raised to separate the lower layer of water, and the upper layer of material is dehydrated by reflux. It is less than 0.5%, and then the qualified product is obtained by crystallization method. After testing, the yield reaches more than 85%, and the purity reaches more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com