Functional membrane, production method and fabric

A functional film and production method technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of moisture permeability gap, non-flammability, aggravated air pollution, etc. The effect of high water resistance, high air permeability and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) preparation for liquid adjustment

[0033] First, dissolve 5g of sodium carboxymethylcellulose powder with a degree of substitution of 0.5 in 120g of water. After fully dissolving, mix and stir with 100g of water-based polyurethane resin. At the same time, add 0.5g of bridging agent and 0.5g of defoamer, and stir fully Finally, the coating resin liquid ① is formed.

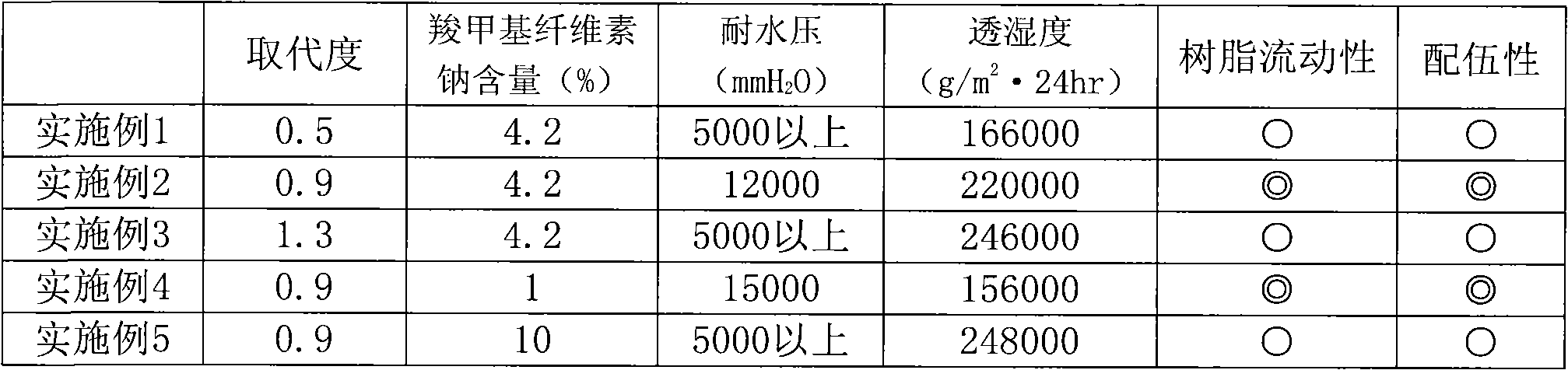

[0034] (2) Preparation of functional film

[0035] Through the coating machine, use the prepared resin liquid ① on the surface of the release paper or release cloth to coat evenly, and then dry and cure in a continuous drying oven (70°C-90°C-130°C-150°C) to obtain Functional film with a thickness of 25 μm. Its performance is shown in Table 1.

Embodiment 2

[0037] (1) preparation for liquid adjustment

[0038] First, dissolve 5g of sodium carboxymethylcellulose powder with a degree of substitution of 0.9 in 120g of water. After fully dissolving, mix and stir with 100g of water-based polyurethane resin. At the same time, add 0.5g of bridging agent and 0.5g of defoamer, and stir fully Finally, a coating resin liquid ② is formed.

[0039] (2) Preparation of functional film

[0040] Through a coating machine, use the prepared resin liquid ② on the surface of the release paper or release cloth to evenly coat, and then dry and cure in a continuous drying oven (70°C-90°C-130°C-150°C) to obtain Functional film with a thickness of 25 μm. Its performance is shown in Table 1.

Embodiment 3

[0042] (1) preparation for liquid adjustment

[0043] First, dissolve 5g of sodium carboxymethylcellulose powder with a degree of substitution of 1.3 in 120g of water. After fully dissolving, mix and stir with 100g of water-based polyurethane resin. At the same time, add 0.5g of bridging agent and 0.5g of defoamer, and stir fully Finally, a coating resin liquid ③ is formed.

[0044] (2) Preparation of functional film

[0045] Through the coating machine, use the prepared resin solution ③ on the surface of the release paper or release cloth to evenly coat, and then dry and cure in a continuous drying oven (70°C-90°C-130°C-150°C) to obtain Functional film with a thickness of 25 μm. Its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com