Erbium-based amorphous composite magnetic cold storage material, preparation method thereof, and cryogenic refrigerator

A technology of cold storage material and composite magnetism, applied in the fields of low temperature physics and material science, can solve problems such as unsatisfactory effects, and achieve the effects of superior processing capability, simple preparation method and strong oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the technical solution of the present invention, the preparation method of the above-mentioned erbium-based amorphous composite magnetic cold storage material comprises the following steps:

[0037] 1) Proportioning of raw materials: elements Er, T, Al, and X according to (Er 0.75 T 0.25 ) a Al b x c For batching, where 75≤a≤85, 15≤b≤25, 0≤c≤5, and a+b+c=100, element T is Ni or Co, element X is selected from Gd, Tb, Dy, Ho One or more of , Tm, Cu, Y, Ag;

[0038] Among them, the purity of all Er, Co, Ni, Al, Gd, Tb, Dy, Ho, Tm, Cu, Y, Ag elements is not less than 99.9wt%;

[0039] 2) Preparation of the master alloy: placing the components obtained in the aforementioned steps of batching in an electric arc furnace in an argon atmosphere adsorbed by titanium, melting (preferably more than 4 times) to mix them uniformly, and obtaining the master alloy ingot after cooling;

[0040] 3) Suction casting: using conventional metal mold casting method, re-melting the mas...

Embodiment 1

[0043] Embodiment 1, erbium-based amorphous alloy composite material (Er 0.75 Ni 0.25 ) 80 Al 17 Gd 3 preparation of

[0044] After the four components of Er, Ni, Al and Gd with a raw material purity of more than 99.9wt% (weight percent) are prepared in a molar ratio of 60:20:17:3, in an electric arc furnace with an argon atmosphere adsorbed by titanium Mix and smelt 5 times to make it evenly mixed, and obtain the master alloy ingot of Er-Ni-A1-Gd quaternary alloy after cooling; then use the conventional metal mold casting method to remelt the ingot, and use the electric arc furnace The suction casting device, the master alloy melt is sucked into the water-cooled copper mold, and the composition can be obtained as (Er 0.75 Ni 0.25 ) 80 Al 17 Gd 3 , An erbium-based amorphous composite magnetic regenerator material with a diameter of 1 mm.

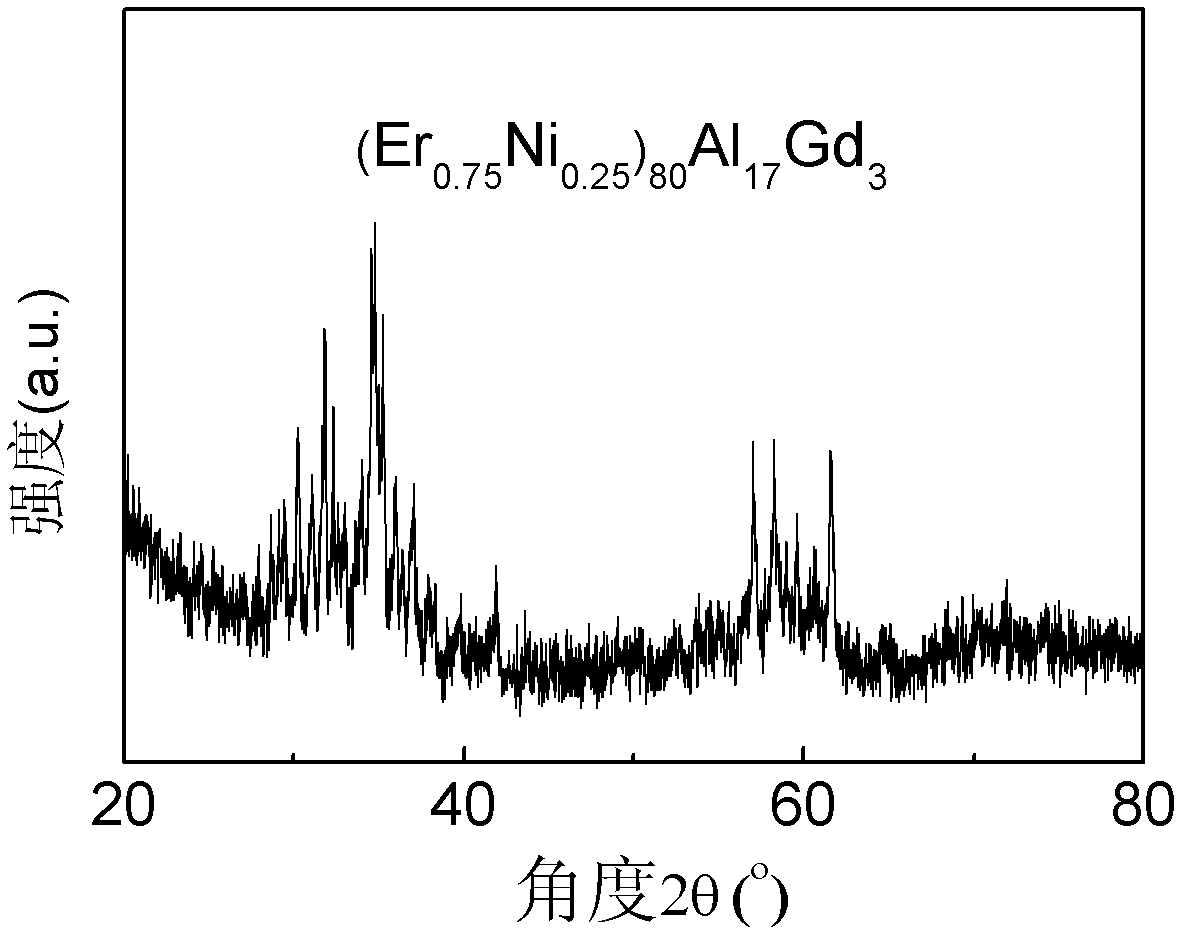

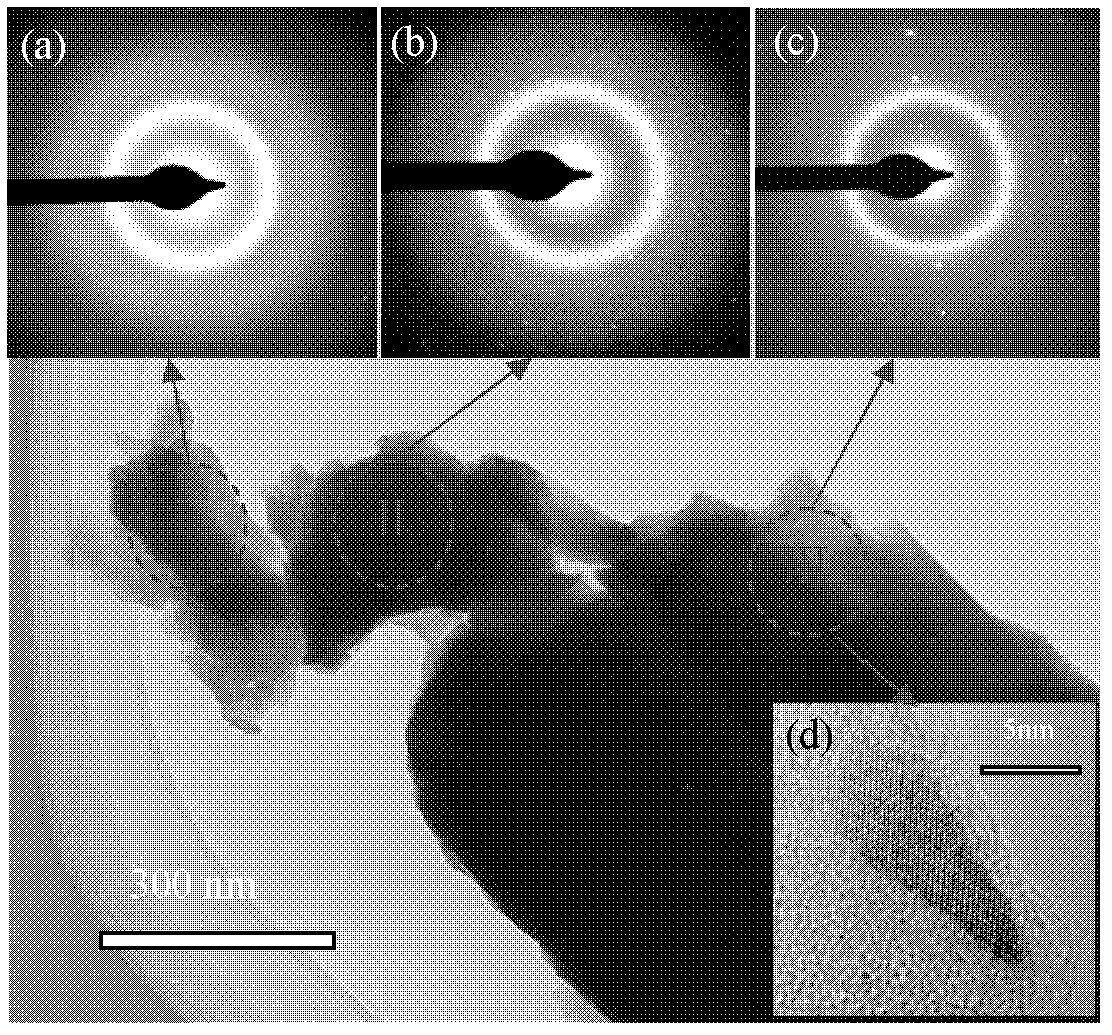

[0045] figure 1 It is the erbium-based amorphous composite magnetic cold storage material (Er 0.75 Ni 0.25 ) 80 Al 17 Gd 3 ...

Embodiment 2~4

[0050] Embodiment 2~4, erbium-based amorphous composite magnetic cold storage material (Er 0.75 Ni 0.25 ) 80 Al 20-x Gd x Preparation of (x=0,1,2)

[0051] Similar to the preparation method of Example 1, an erbium-based amorphous composite magnetic cold storage material (Er 0.75 Ni 0.25 ) 80 Al 20 , (Er 0.75 Ni 0.25 ) 80 Al 19 Gd 1 and (Er 0.75 Ni 0.25 ) 80 Al 18 Gd 2 .

[0052] Figure 5 is the X-ray diffraction pattern of this series of erbium-based amorphous composite magnetic regenerator materials, it can be seen that the alloy (Er 0.75 Ni 0.25 ) 80 Al 20 , (Er 0.75 Ni 0.25 ) 80 Al 19 Gd 1 and (Er 0.75 Ni 0.25 ) 80 Al 18 Gd 2 with (Er 0.75 Ni 0.25 ) 80 Al 17 Gd 3 The structure of the same amorphous alloy composite.

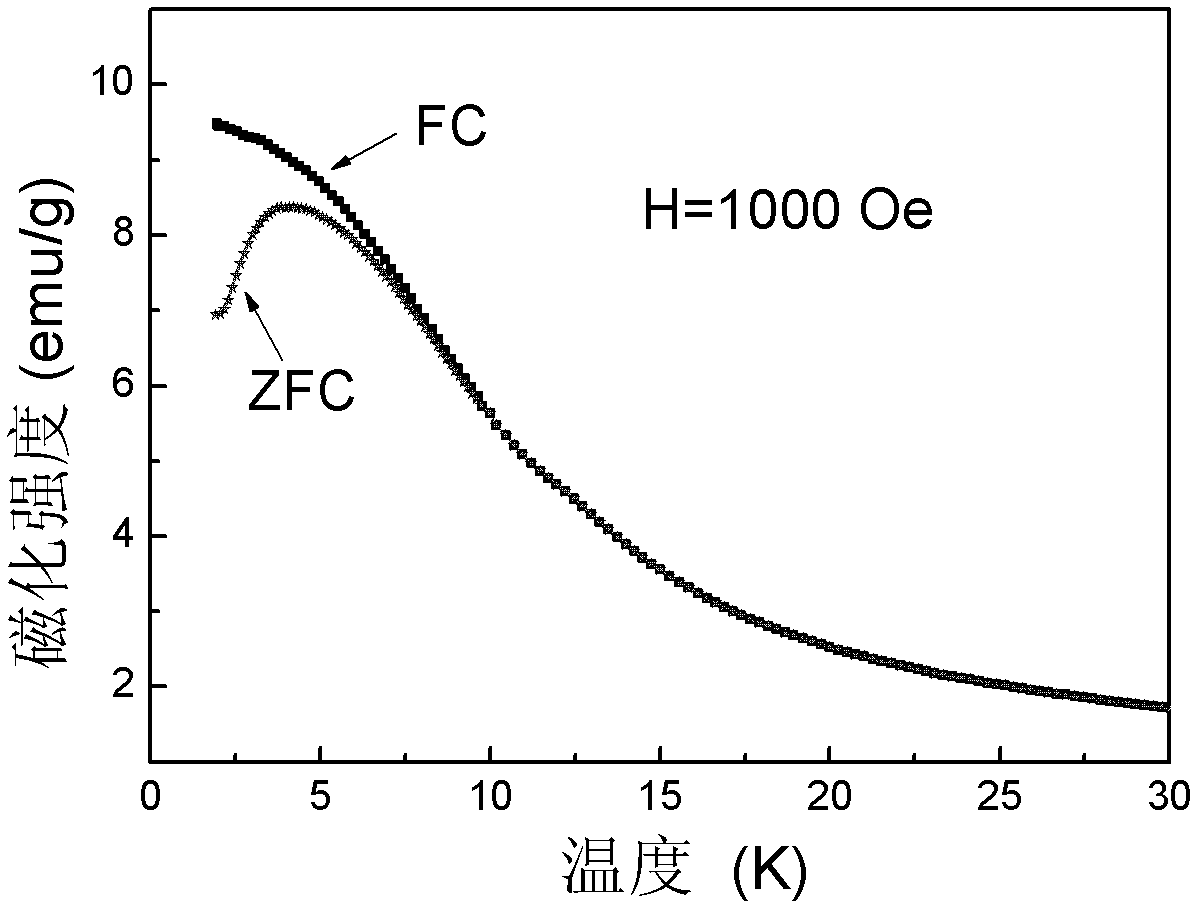

[0053] Figure 6 Shown is (Er prepared by embodiment 2 0.75 Ni 0.25 ) 80 Al 20 and (Er prepared in Example 1 0.75 Ni 0.25 ) 80 Al 17 Gd 3 From the curve of magnetization versus temperature, it can be seen that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com