Direct buried type all-welded insulation ball valve

A thermal insulation ball valve, full welding technology, applied in the direction of thermal insulation, valve device, pipeline protection, etc., can solve the problems of high welding cost of the interlayer, unfavorable maintenance and maintenance, and increased installation cost, so as to facilitate maintenance and maintenance and reduce friction coefficient, the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

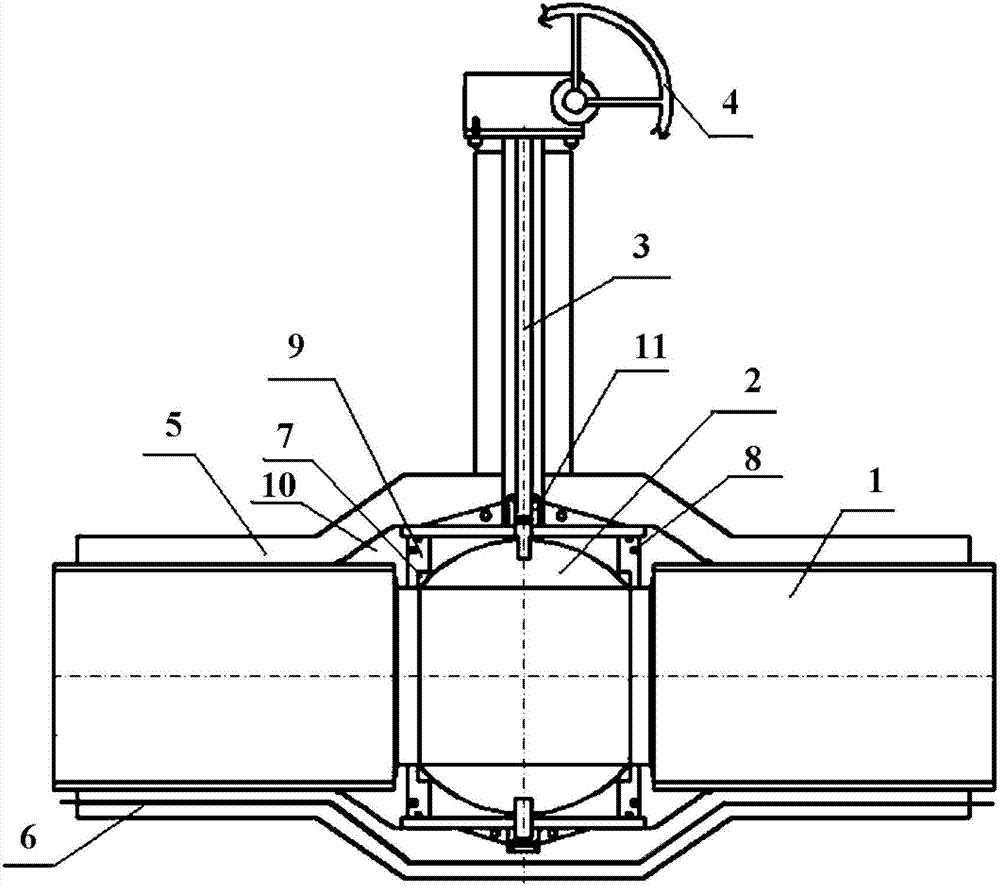

[0022] like figure 1 As shown, the present invention provides a direct-buried fully welded thermal insulation ball valve, which includes a valve body 1 with a fluid passage inside, a stainless steel ball 2 with a hole inside placed in the center of the fluid passage, a valve stem 3 connected to the upper end of the stainless steel ball, and Connect the handle 4 on the upper end of the valve stem. The valve body consists of a seamless steel pipe layer, a foam polyurethane layer 5 and a plastic plate layer from the inside to the outside. The polyurethane foam layer 5 has three copper wires 6 connected to the leakage alarm device; there is a stainless steel ball on the periphery. Valve seat 7, the periphery of valve seat 7 has valve seat support 9, and described valve seat support 9 is supported by spring 8 and is connected with a valve cover 10, and the bottom end of stainless steel ball 2 is connected with described valve body by fixed shaft; Valve stem 3 is Extend the rod, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com