Recovery method for hydrogen sulfide gas in conveying process

A recovery method and technology in the transportation process, which is applied in the field of hydrogen sulfide, can solve the problems of non-reporting, misreporting or misreporting, and achieve the effects of reducing pollution, less one-time investment, and avoiding safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

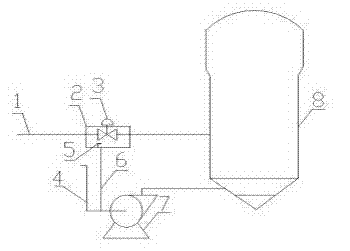

[0014] Take this method as an example in Wengfu Group Co., Ltd. 2×400,000 tons / year pyrite acid production plant: between the hydrogen sulfide pipeline 1 and the inlet pipe 4 of the roasting fan, connect the pipe 6 from the inlet pipe 4 of the roasting fan , add a sealing box 2 at the valve 3 and the place where it is easy to leak, introduce the pipeline from the inlet 4 of the roasting fan into the bottom of the valve 3 in the box of the sealing box 2 or the place where it is easy to leak, and place hydrogen sulfide at the mouth of the box in the box 2 Detector 5, sealing box 2 design inspection door, operating hand wheel is arranged outside sealing box 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com