Quantitative analysis method of nitrocellulose component in propellant

A quantitative analysis, nitrocellulose technology, applied in the direction of material inspection products, fuel oil testing, etc., can solve the problems of large error in analysis results, slow speed, and many operation steps, and achieve the effect of rapid measurement and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Content determination of nitrocellulose component in XX main charge:

[0033] 1) Use a spatula to process the XX main charge sample into flower flakes, the thickness of which is less than 2mm, accurately weigh 1g and place it in a No. 3 filter cup with constant weight, extract with ether for 2 hours, and the extraction temperature is 58°C;

[0034] 2) Dry the No. 3 filter cup in a drying oven at 100°C±5°C for 1 hour, then place it in a desiccator to cool naturally for 30 minutes, weigh it, and record the mass;

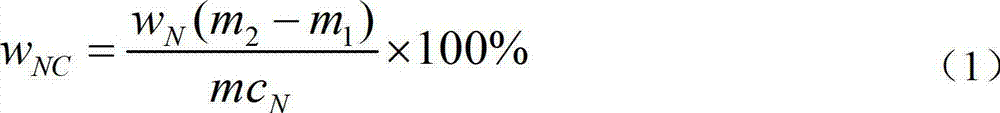

[0035] 3) The insoluble matter is directly quantified by an elemental analyzer with a large sample volume, sample volume: 80 mg, combustion method: secondary combustion; calculate the content of nitrocellulose in the main charge of XX according to formula (1), And compared with the results of the subtraction method, the specific data are shown in Table 1.

[0036] Content of nitrocellulose components in table 1XX main charge

[0037] Sam...

Embodiment 2

[0038] Embodiment 2: Determination of nitrocellulose component content in XX endurance drug:

[0039] 1) Use a spatula to process the sample of XX endurance drug into flakes, the thickness of which is less than 2mm, accurately weigh 1g and place it in the No. 3 filter cup with constant weight, extract with isopropyl ether for 2 hours, and the extraction temperature is 70°C;

[0040] 2) After drying No. 3 filter cup in a drying oven at 100°C for 1 hour, place it in a desiccator to cool naturally for 30 minutes, weigh it, and record the mass;

[0041] 3) The insoluble matter is directly quantified by an elemental analyzer with a large sample volume, sample volume: 100mg, combustion method: secondary combustion; use formula (1) to calculate the content of nitrocellulose in XX battery life medicine, And compared with the results of the subtraction method, the specific data are shown in Table 2.

[0042] Content of nitrocellulose components in table 2XX continuation medicine

[0...

Embodiment 3

[0045] Content of nitrocellulose in XX propellant containing ammonium perchlorate

[0046] 1) Use a spatula to process the XX ammonium perchlorate-containing propellant sample into flakes, the thickness of which is less than 2mm. Accurately weigh 1g and place it in a No. 3 filter cup with constant weight, and mix it with isopropyl ether and diethyl ether Solvent extraction for 2 hours, the extraction temperature is 60°C, and the volume ratio of diethyl ether to isopropyl ether is 2:1;

[0047] 2) Transfer all the ether and isopropyl ether insolubles in No. 3 filter cup to a beaker, add 30mL warm water, soak for 40min, and keep the water temperature at 50°C;

[0048] 3) Transfer all the insoluble matter in the beaker after soaking in water to the original No. 3 filter cup, wash it with water 4 times, drain it, dry it in a drying oven at 100°C±5°C for 1 hour, and then cool it naturally in a desiccator 30min, weigh and record the mass;

[0049]4) The insoluble matter is directl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com