Manufacturing method for polymer light-emitting diode including electron transfer layer

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of light-emitting materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., and can solve the problems that the light-emitting performance of light-emitting diodes cannot meet the needs, the preparation process of flexible light-emitting diodes is complicated, and the cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Polymer Ia: 3-(N-isopropyl-4-methylcyclohexylcarboxamido)-7-phenylbenzo[b]thiophene-2-carboxylic acid

[0079]

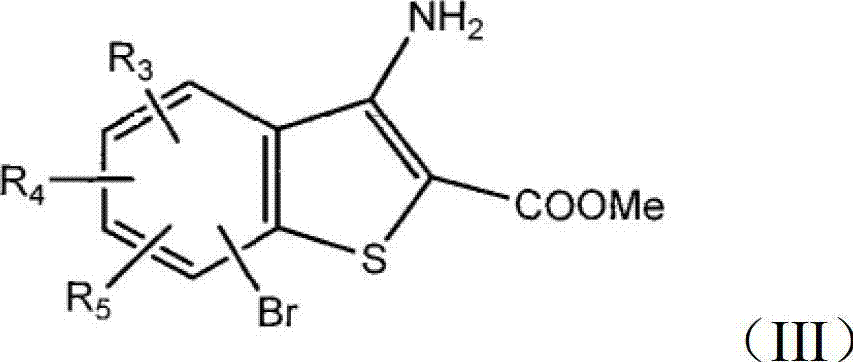

[0080] Firstly, intermediate IIIa: 3-amino-7-bromobenzo[b]thiophene-2-methyl carboxylate is synthesized, and the target polymer is synthesized from intermediate IIIa.

[0081]

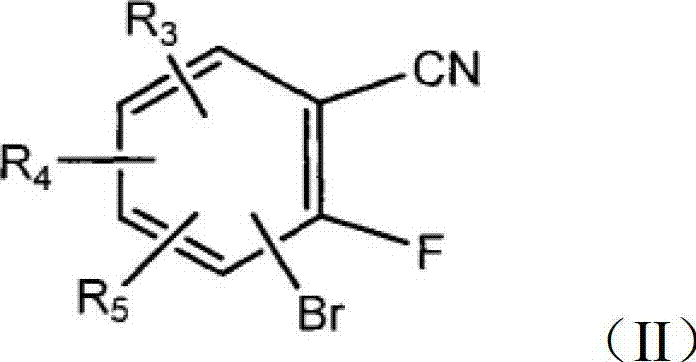

[0082] According to the synthetic route of the present invention, 3-bromo-2-fluorobenzonitrile (5.0g, 25.1mmol) was dissolved in 20.0ml DMF under the protection of nitrogen, and sodium carbonate (5.3g, 50.0mmol) was added and cooled to 0℃. Under stirring conditions, methyl thioglycolate (2.9 g, 27.5 mmol) was added dropwise, and the reaction solution was raised to room temperature and stirred overnight. After adding water, a white solid precipitated, filtered, washed the solid with water and petroleum ether, and dried to obtain a white powder (6.4 g) with a yield of 89.5%.

[0083] 1 H NMR(CDCl 3 , 300MHz) δ7.64-7.60(m, 2H), 7.29-7.24(m, 1H), 5.86(br, 2H), 3.90(s, 3H); ESI-MS m / z 284(M-H) -...

Embodiment 2

[0100] Polymer Ib: 3-(N-isopropyl-4-methylcyclohexylcarboxamido)-6-phenylbenzo[b]thiophene-2-carboxylic acid

[0101]

[0102] Synthesis of intermediate IIIb

[0103] Methyl 3-amino-6-bromobenzo[b]thiophene-2-carboxylate

[0104]

[0105] According to the synthetic route of the present invention, 4-bromo-2-fluorobenzene cyanide (5.0g, 25.1mmol) was dissolved in 20.0ml DMF under the protection of nitrogen, sodium carbonate (5.3g, 50.0mmol) was added and cooled to 0°C, while stirring Methyl thioglycolate (2.9g, 27.5mmol) was added dropwise under the conditions of, and the reaction solution was raised to room temperature and stirred overnight. After adding water, a white solid precipitated, filtered, washed the solid with water and petroleum ether, and dried to obtain a white powder (6.0 g) with a yield of 83.9%.

[0106] 1 H NMR(CDCl 3 , 300MHz) δ 7.88 (s, 1H), 7.48 (s, 2H), 5.88 (s, 2H), 3.89 (s, 3H); ESI-MS m / z 284 (M + -H + ).

[0107] The following steps follow the method for prepar...

Embodiment 3

[0110] Polymer Ie: 3-(nitrogen-4-methylcyclohexylcarboxamido)-7-phenylbenzo[b]thiophene-2-carboxylic acid

[0111]

[0112] According to the method of preparing polymer Ia in Example 1, polymer Ie can be prepared.

[0113] 1 H NMR (DMSO-d6, 300MHz) δ9.99 (s, 1H), 7.82-7.79 (m, 3H), 7.67-7.59 (m, 5H), 2.51-2.48 (m, 1H), 2.08-2.04 (m , 2H), 1.88-1.84 (m, 2H), 1.66-1.44 (m, 3H), 1.12-1.07 (m, 2H), 1.00 (d, J=6.3 Hz, 3H);

[0114] ESI-MS m / z 392(M-H) - .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com