Novel metamaterial

A metamaterial, a new type of technology, applied in the field of materials, which can solve problems such as inability to change the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

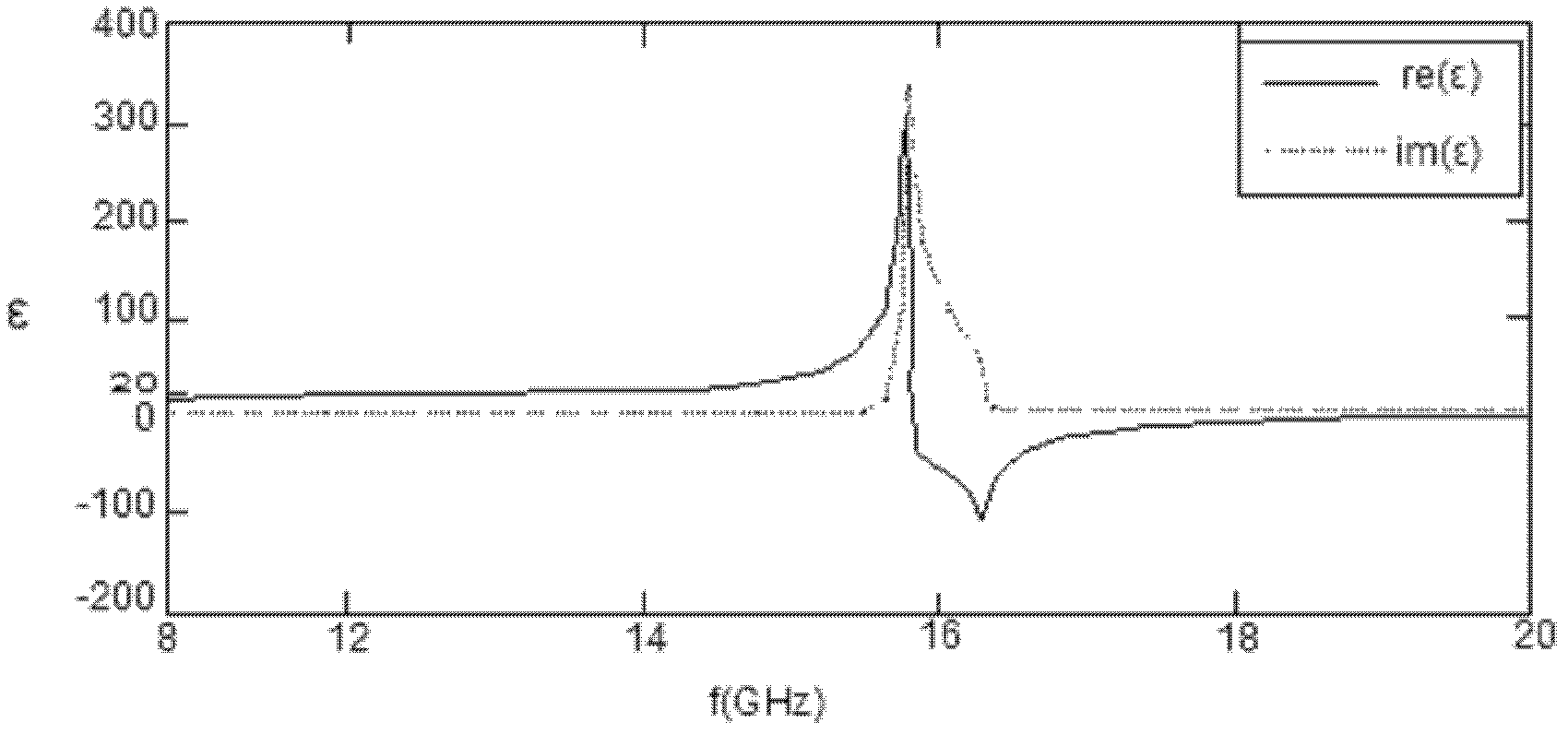

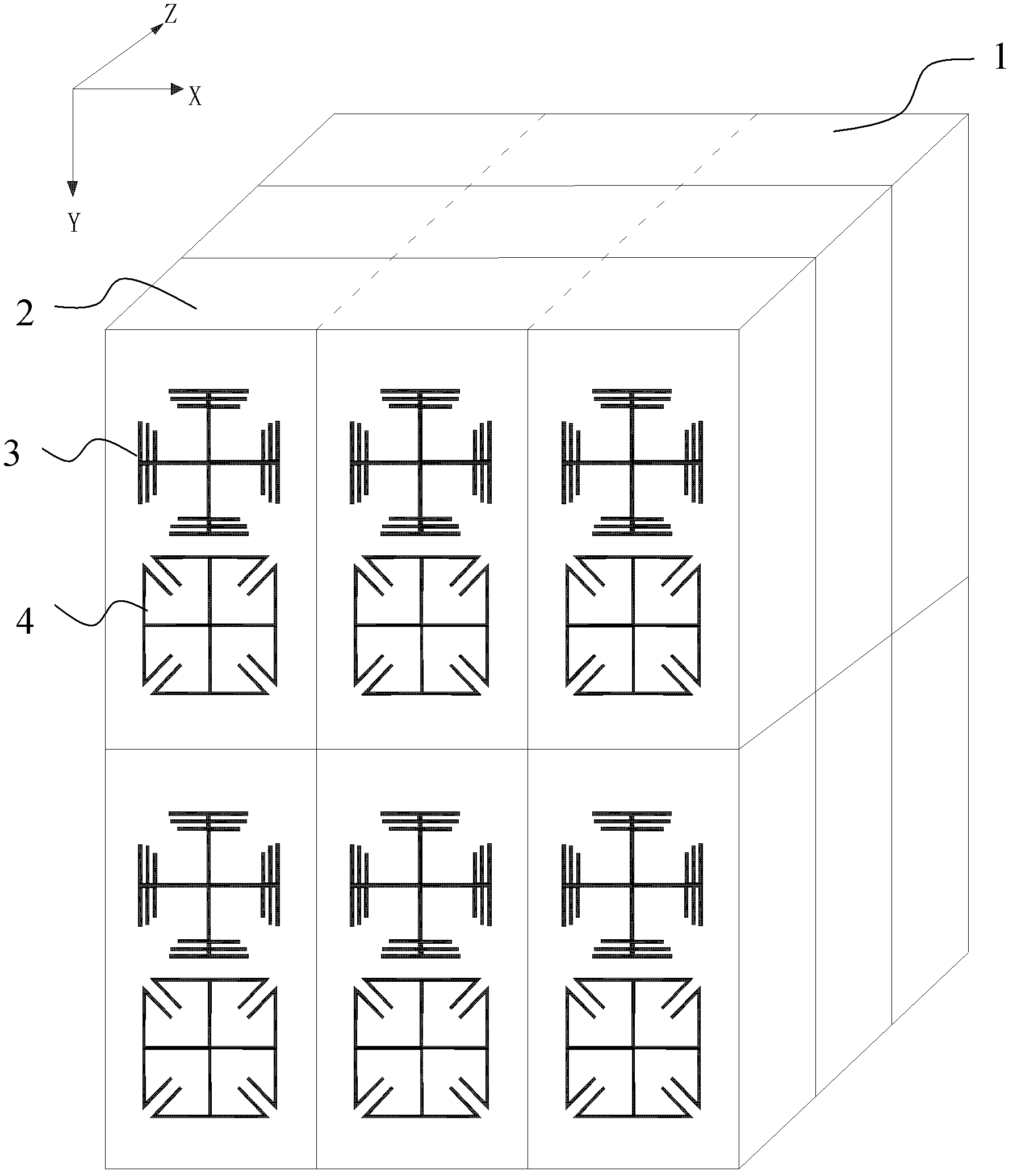

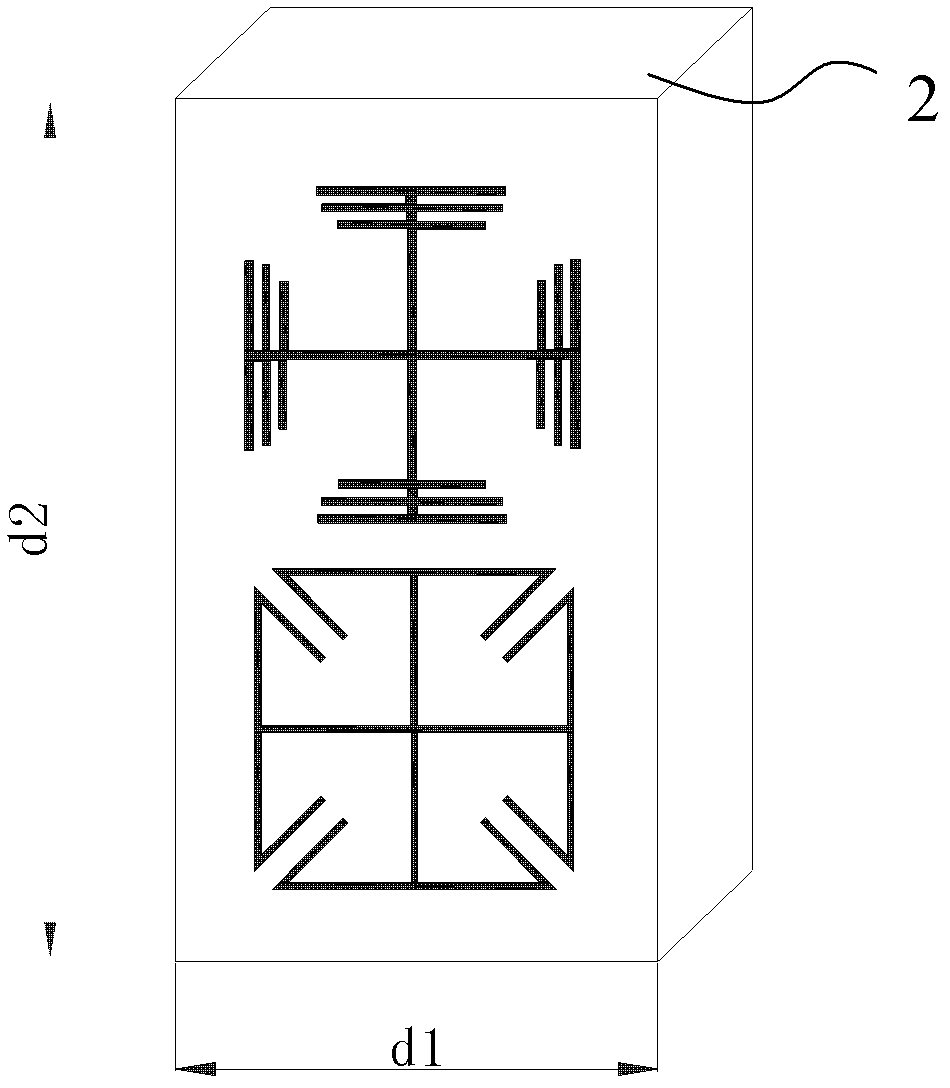

[0032] When artificial microstructures such as Figure 5 As shown, a1=2.8 mm, a2=2.4 mm, a3=2 mm, a4=3 mm, a5=0.1 mm, the artificial microstructure 4 is as Figure 4 As shown, c1=c2=2.89 mm, c3=0.184 mm, c4=0.75 mm, such as image 3 For the substrate unit shown, d1=4 mm, d2=8 mm, the simulation diagram obtained by using the above parameters is as follows Figure 6 shown by Figure 6 The solid line in the figure shows that the dielectric constant characteristic of this material has the characteristics of multi-resonance, and the dielectric constant remains unchanged and is 20 in the frequency band (0GHz~8GHz). It can be seen that this material has a wide frequency and high dielectric Constant characteristics, given by Figure 6 It can also be seen that the dielectric constant gradually increases from zero in a certain frequency band (11.7GHz to 13.3GHz), and it can be seen from the dotted line that the imaginary part of the corresponding dielectric constant is close to zero ...

Embodiment 2

[0034] The difference from Embodiment 1 lies in the size of the first artificial microstructure 3, and the artificial microstructure 3 after the size increase is as follows: Figure 7 As shown, a1=3.6 mm, a2=3.2 mm, a3=2.8 mm, a4=3.8 mm, a5=0.1 mm, the artificial microstructure 4 is as Figure 4 As shown, c1=c2=2.89 mm, c3=0.184 mm, c4=0.75 mm, such as image 3 For the substrate unit shown, d1=4 mm, d2=8 mm, the simulation diagram obtained by using the above parameters is as follows Figure 8 shown by Figure 8The solid line in the figure shows that the dielectric constant characteristic of the material has the characteristics of multi-resonance, and the dielectric constant is constant in the frequency band (1GHz-7GHz) and is 20. It can be seen that the material has a broadband high dielectric constant The dielectric constant gradually increases from zero in a certain frequency band (11.7GHz to 15GHz), and it can be seen from the dotted line that the imaginary part of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com