Semiconductor template substrate, light-emitting element using a semiconductor template substrate, and a production method therefor

一种半导体、发光器件的技术,应用在半导体/固态器件制造、半导体器件、电气元件等方向,能够解决发光器件性能降低、高漏电流、发光器件芯片产量减少等问题,达到简化制造工艺的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

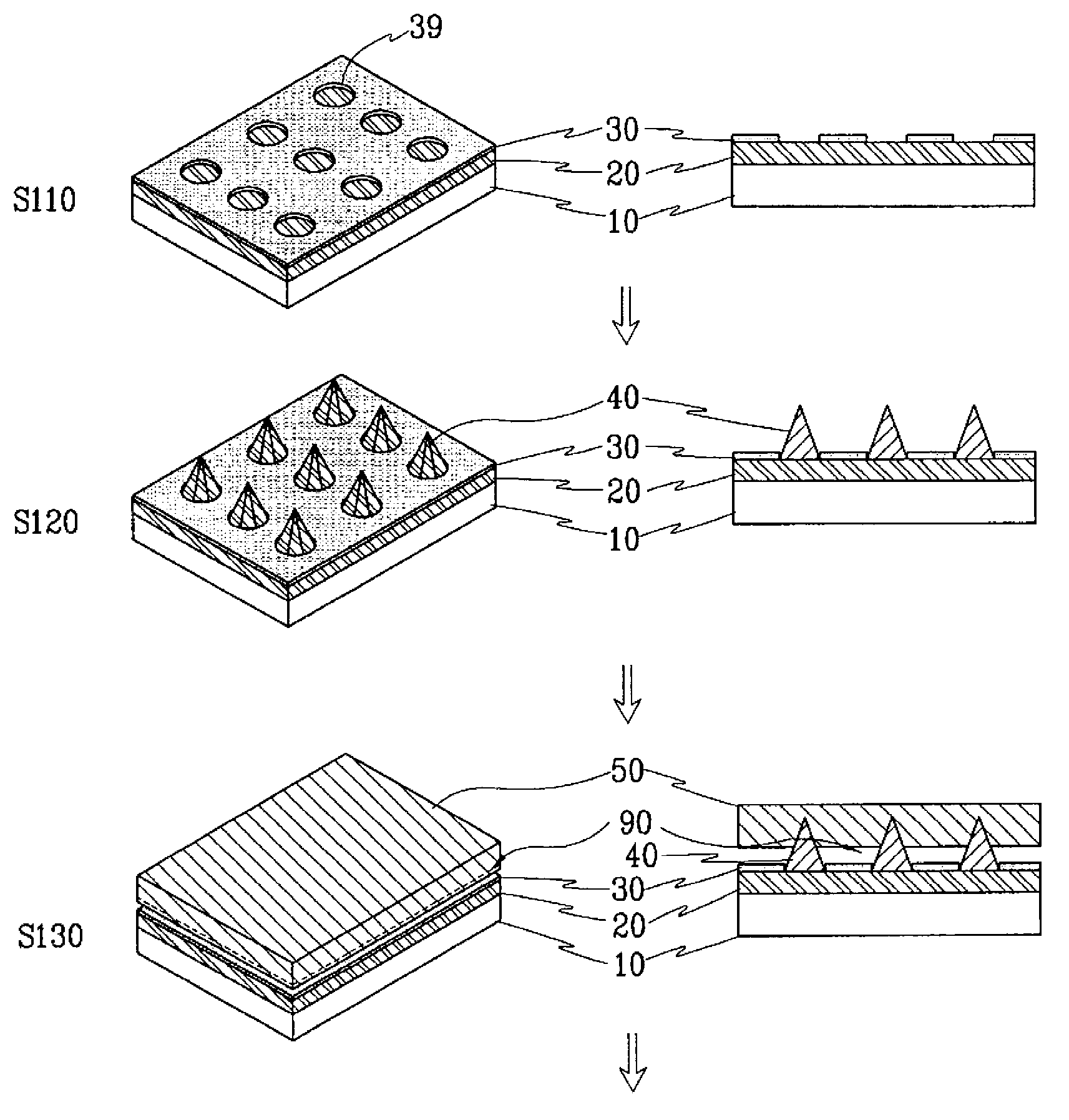

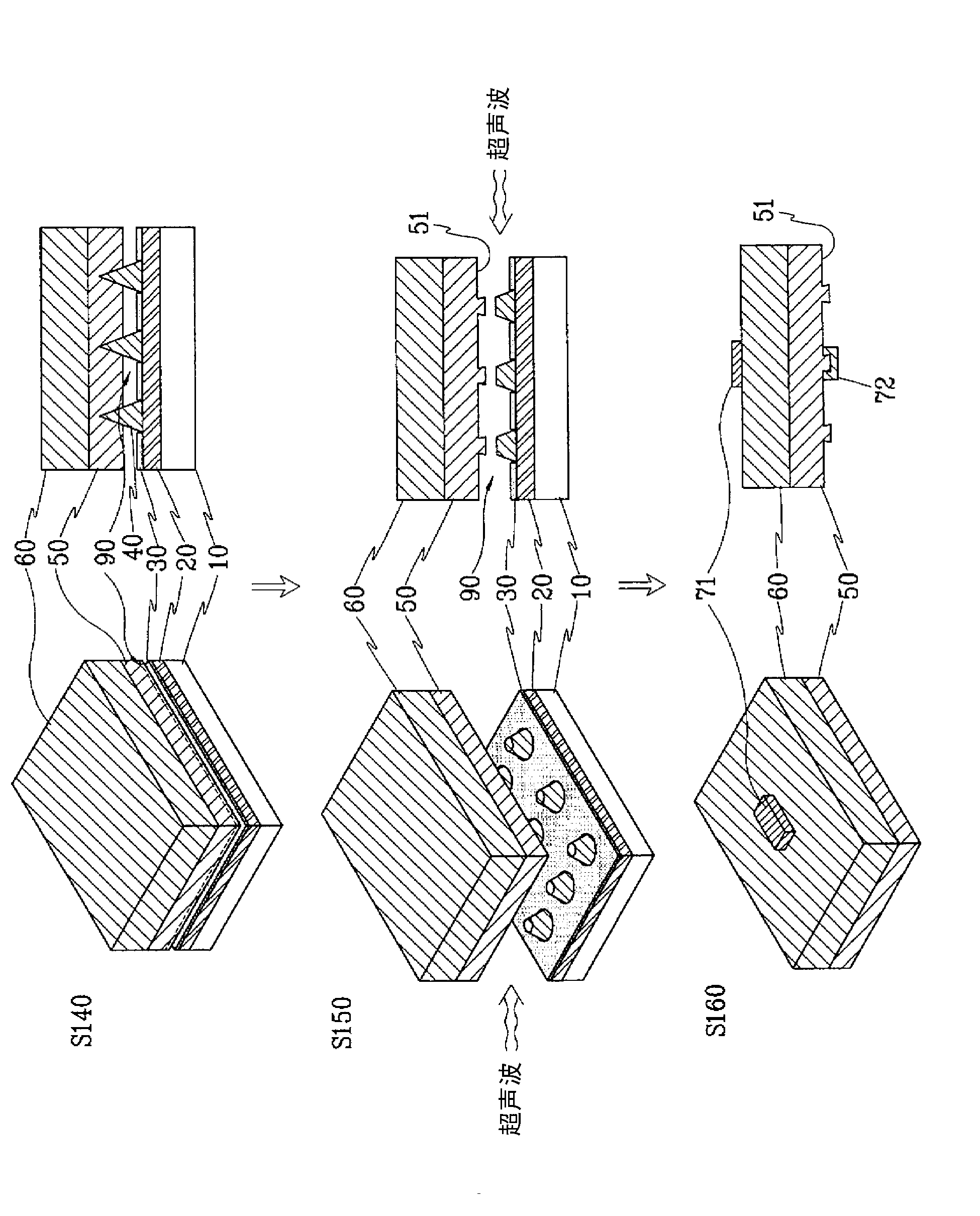

[0027] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those skilled in the art can easily implement the embodiments.

[0028] First, a semiconductor crystal manufacturing method according to an embodiment of the present invention will be described with reference to FIGS. 1A and 1B . For example, this embodiment is an embodiment in which n-type GaN crystals are grown using a sapphire substrate. However, materials used for the substrate and buffer layer, semiconductor layer, and light emitting stack structure are not limited thereto.

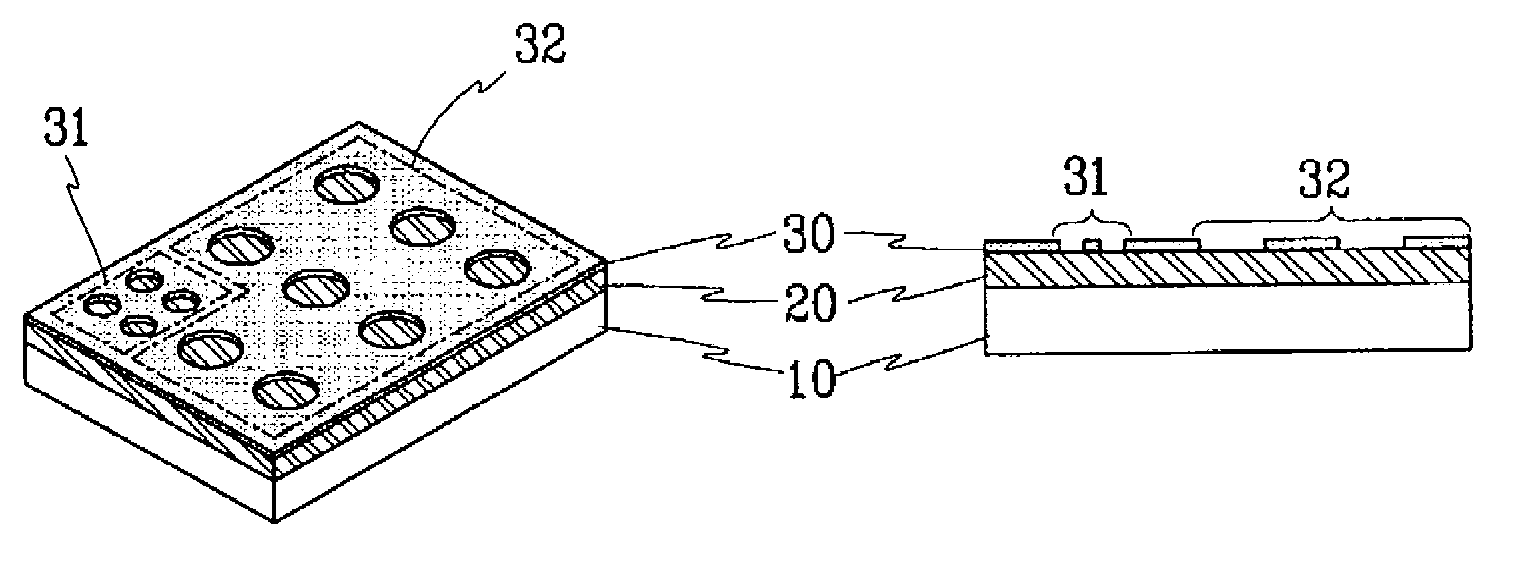

[0029] In operation S110 , a buffer layer 20 is formed on the insulating substrate 10 , and a mask layer 30 having a plurality of exposure patterns 39 is formed on the buffer layer 20 . In FIG. 1A , the exposure pattern 39 is shown in a circular shape. However, the exposure pattern 39 may be formed in a polygonal shape such as a quadrangle, a triangle, or a hexago...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com