Cast-rolling production method of lead alloy plate

A production method and technology of lead alloy, applied in the direction of metal rolling, etc., can solve the problems of multiple independent processes, unreasonable, large energy consumption and waste of materials, etc., and achieve the effects of reducing energy consumption, saving materials, and shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

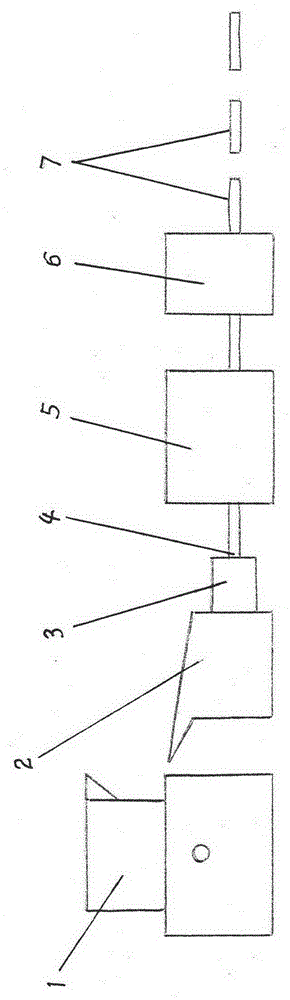

[0013] Embodiment 1: the cast-rolling production method of lead alloy plate

[0014] The casting and rolling production method of the lead alloy sheet material, the lead alloy percentage composition is 99.85% of lead, 0.1% of silver, 0.04% of calcium and 0.01% of strontium.

[0015] The production method process is as follows: first step, put lead, silver, calcium and strontium into melting furnace 1 according to the proportion of components for melting; second step, pour the smelted lead alloy into holding furnace 2, the temperature Keep it within 400°C±10°C; the third step is to reflow the lead alloy into the crystallizer 3, and the temperature is controlled within 250°C±50°C; the fourth step is to pass the crystallized lead alloy material through the nozzle 4 Introduce the casting-rolling machine 5, the casting-rolling speed is 0.10 m / min; the fifth step, introduce the cast-rolled lead alloy plate into the shearing machine 6, and cut out the lead alloy plate 7 that meets th...

Embodiment 2

[0017] Embodiment 2: the cast-rolling production method of lead alloy plate

[0018] The casting and rolling production method of the lead alloy sheet material, the lead alloy percentage composition is 98.85% of lead, 0.9% of silver, 0.15% of calcium and 0.1% of strontium.

[0019] The production method process is as follows: first step, put lead, silver, calcium and strontium into melting furnace 1 according to the proportion of components for melting; second step, pour the smelted lead alloy into holding furnace 2, the temperature Keep it within 400°C±10°C; the third step is to reflow the lead alloy into the crystallizer 3, and the temperature is controlled within 250°C±50°C; the fourth step is to pass the crystallized lead alloy material through the nozzle 4 Introduce the casting-rolling machine 5 with a casting-rolling speed of 0.50 m / min; the fifth step is to introduce the cast-rolled lead alloy plate into the shearing machine 6 to cut out the lead alloy plate 7 that meet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com