Composite laminate with improved shock strength, as well as preparation method and use thereof

A technology of impact strength and composite layer, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, applications, etc., can solve the problems of constant thickness and weight, and achieve the effect of improving impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] The present invention also provides a method of making a composite laminate having improved impact strength, said method comprising:

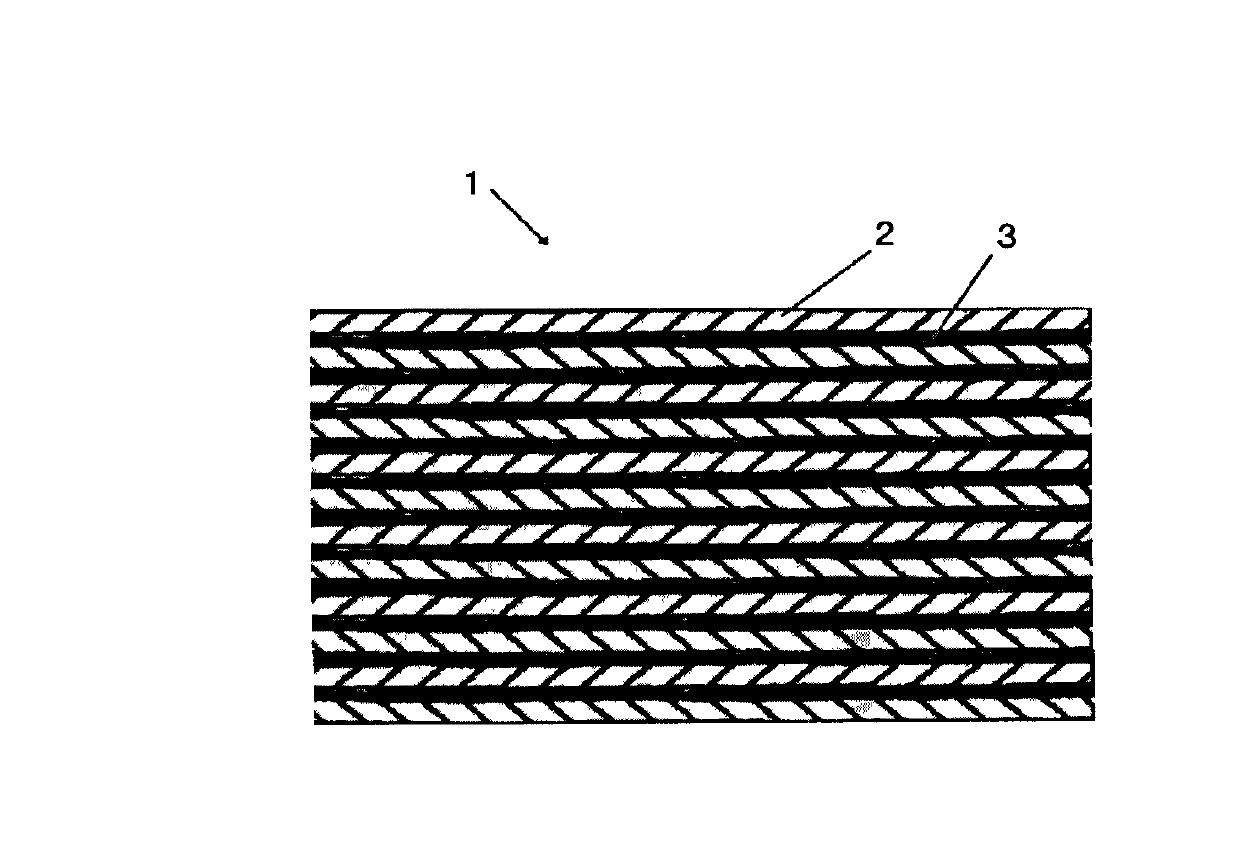

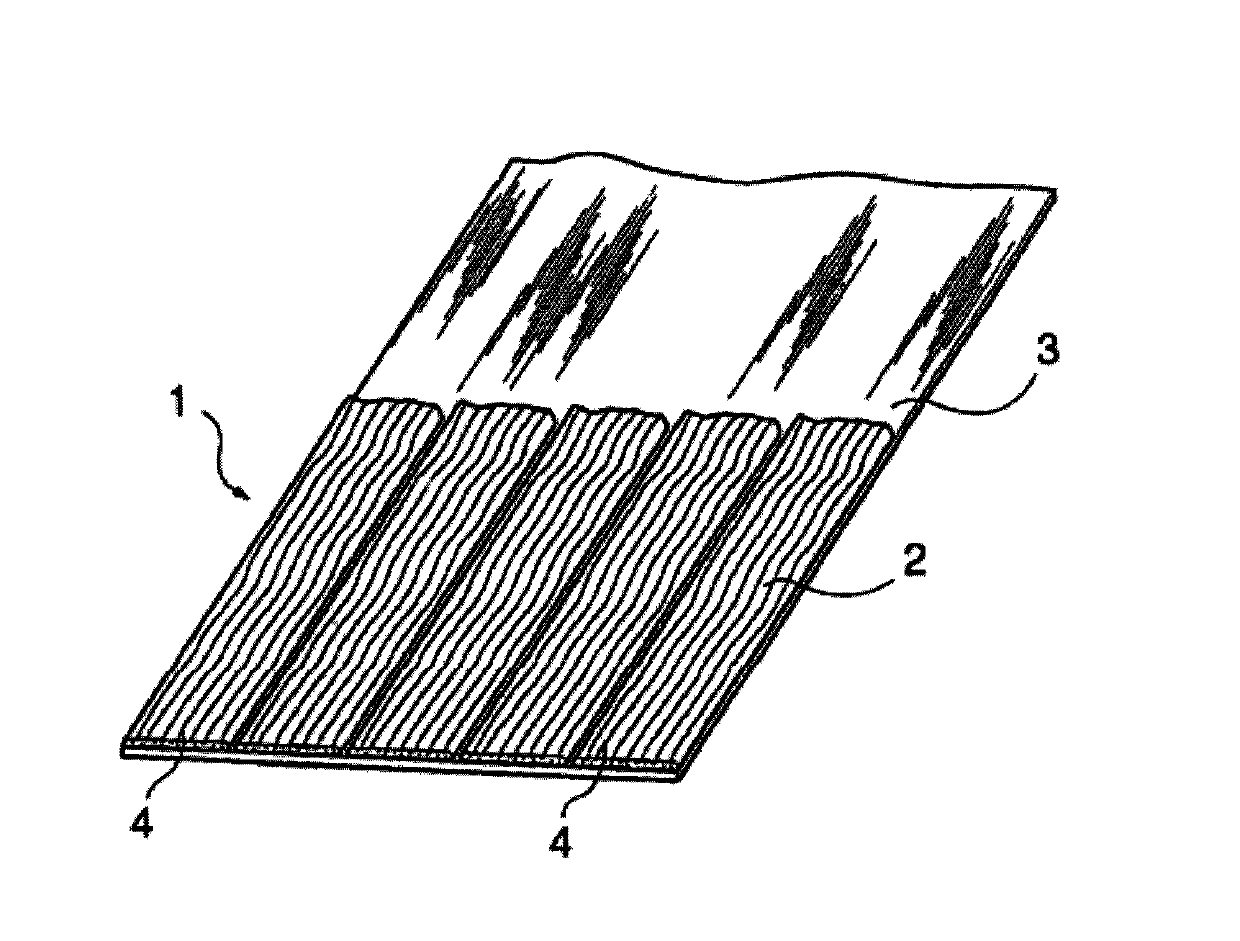

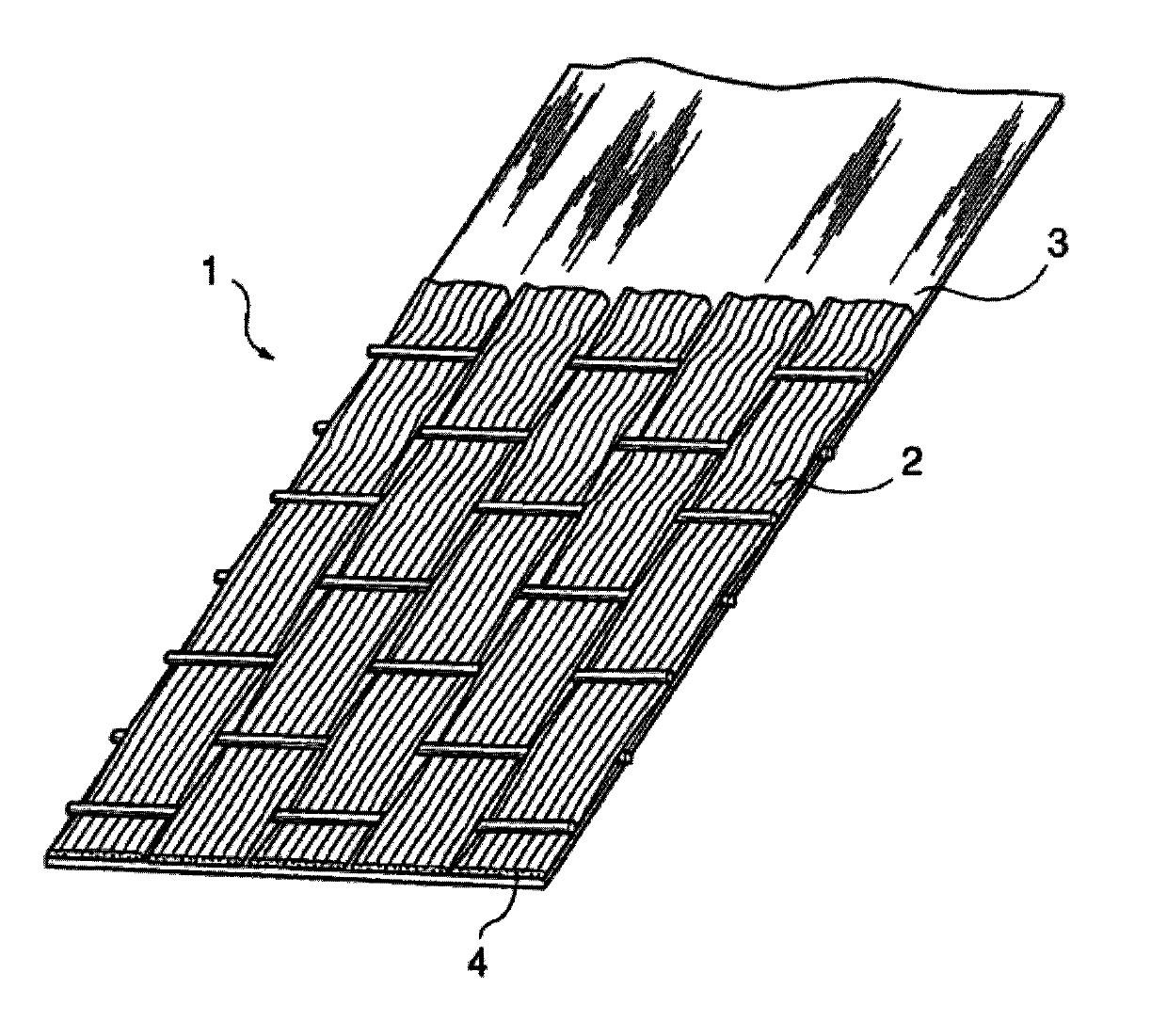

[0088] (i) provide multi-layer carbon fiber fabric layer (a) and multi-layer non-woven thin felt (b), wherein said carbon fiber fabric is woven two-way cloth or unidirectional cloth, and said non-woven thin felt is made of para-aromatic Composition of family polyamide;

[0089] (ii) impregnating said carbon fiber fabric layer (a) with impregnating epoxy resin system to obtain impregnated carbon fiber fabric layer (A);

[0090] (iii) placing at least one impregnated carbon fiber fabric layer (A) as the first outer surface layer;

[0091] (iv) placing at least one layer of non-woven thin mat (b) and at least one layer of impregnated carbon fiber fabric (A) in an alternating manner until the composite laminate has a total thickness of 0.5-30mm and its second outer surface The facing layer is also an impregnated carbon fiber fabric layer (...

Embodiment

[0105] The present invention is further described below in the form of examples, but the materials, methods and examples of the present invention are only illustrative, not restrictive.

[0106] Material:

[0107] a) Unidirectional carbon fiber cloth prepreg

[0108] Purchased from Wuxi Tianniao Composite Material Company, the weight per unit area is 185g / m 2 , containing 120g / m 2 Carbon fiber unidirectional cloth, the bulk density of the carbon fiber cloth is 1.80g / cm 3 , with a thickness of 0.067mm and impregnated with an epoxy resin system. The recommended curing conditions for this prepreg are: 130°C, over 30 minutes;

[0109] b) Non-woven thin mat of para-aramid

[0110] use Staple fibers, chemically prepared into non-woven thin mats, with a weight per unit area of 15 g / m 2 , the bulk density of the non-woven felt is 1.44g / cm 3 , the thickness is 0.01mm.

[0111] c) Nylon non-woven thin felt

[0112] Nylon short fibers (Wuxi Belt Tape Co., Ltd.) are used to p...

Embodiment 1

[0118] Example 1: Preparation of Composite Laminates of the Invention

[0119] Set the weight per unit area to 185g / m 2 The unidirectional carbon fiber cloth prepreg is cut into a sheet of 300mm×300mm; at the same time, the weight per unit area is 15g / m 2 of The non-woven thin mat is also cut into a sheet of 300mm×300mm; first place a layer of prepreg (that is, the impregnated carbon fiber fabric layer) as the first outer surface layer, and place a layer of non-woven thin mat and One ply of prepreg such that between every two plies of prepreg there is a layer Non-woven thin mat, in which the prepreg sheets are stacked in the same fiber direction (warp direction), so that 12 layers of prepreg sheets and 11 layers are shared Non-woven thin mats were prepared together by A composite laminate preform composed of non-woven thin mat and carbon fiber reinforced polymer, the preform is placed on a flat aluminum mold, and then the mold is transferred to a hot press that has bee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com