Fullerene compound and preparation method thereof

A fullerene complex and fullerene technology, applied in the field of compounds, can solve the problems of poor biocompatibility of fullerenes, and achieve the effects of avoiding the addition of toxic reagents, maintaining biological properties, and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

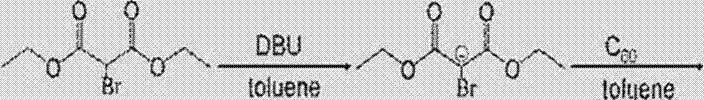

[0036] Preparation of fullerene ester derivatives:

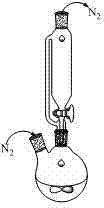

[0037] The reactor is a round bottom flask and a constant pressure funnel; first in the round bottom flask, 20mg C 60 Dissolve in 10mL toluene to obtain the first mixed solution, then add 14.2mL diethyl bromomalonate to the first mixed solution, stir for 30min; add 13ul DBU (i.e. 1,8-diazepine Bicyclo[5.4.0]undec-7-ene), and add 10ml of toluene to dilute to obtain the second mixed solution, then feed nitrogen into the reactor, such as figure 1 As shown, nitrogen enters from the round-bottomed flask and is discharged from the constant-pressure funnel. After nitrogen gas is introduced for 20 minutes, the constant-pressure funnel is opened and the second mixed solution is slowly added dropwise to the round-bottomed flask below. After the addition, continue to react for two The reaction product was obtained in 1 hour, and the fullerene ester derivatives with different addition numbers were separated after the reaction product w...

Embodiment 2

[0039] Preparation of fullerene complexes:

[0040] 0.5mgC 60 Monoaddition ester derivatives (i.e. fullerene ester derivatives are C 60 Mono-addition product) and 5g PVP (polyvinylpyrrolidone) were dissolved in 100ml ethanol, stirred for 12 hours, evaporated to dryness, redissolved the dried solid in water, heated to evaporate residual ethanol, and dried the obtained product For fullerene complexes. It can be understood that the fullerene di-addition ester derivatives and fullerene tri-addition ester derivatives can be compounded in the same way, or these mixtures with different addition numbers can be compounded together.

Embodiment 3

[0042] 50mgC60 Monoaddition ester derivatives (i.e. fullerene ester derivatives are C 60 Mono-addition product) and 5g PVP (polyvinylpyrrolidone) were dissolved in 100ml ethanol, stirred for 12 hours, evaporated to dryness, redissolved the dried solid in water, heated to evaporate residual ethanol, and dried the obtained product For fullerene complexes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com