Double-component organic silica gel for packaging of large power IGBT (insulated bipolar translator) and preparation method thereof

A two-component, high-power technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of high volatile content and low dielectric strength, and achieve low volatile content, good stability, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

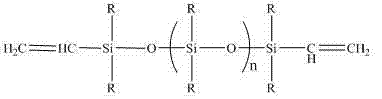

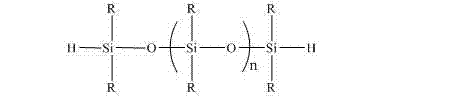

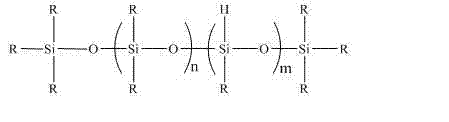

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh 1000g of vinyl-terminated silicone oil with a viscosity of 800mpa.s and a mass fraction of vinyl of 0.35%, and 2.0g of a complex of chloroplatinic acid-vinylsiloxane with a concentration of 5000ppm, and add them to the planetary mixer. Under the conditions of 1000r / min and 5-20r / min revolution, stir at room temperature for 0.5-1h to obtain component A, pack and place it for use; accurately weigh 850g of vinyl-terminated silicone oil with a viscosity of 800mpa.s and a vinyl mass fraction of 0.35%. 193g of a chain extender with a viscosity of 30cst, 7.5g of a crosslinking agent with a viscosity of 65cst, 2.0g of 1-ethynylcyclohexanol, and 0.5g of dibutylhydroxytoluene were added to the planetary mixer in turn, and the rotation speed was 200~1000r / min, revolution speed 5-20r / min, stirring at room temperature for 0.5-1h, to obtain component B, packaged and placed for use.

[0026] Among them, the terminal vinyl silicone oil is molecularly distilled for 3 h...

Embodiment 2

[0031] Accurately weigh 1000g of vinyl-terminated silicone oil with a viscosity of 1000mpa.s and a mass fraction of vinyl of 0.3%, and 2.0g of a complex of chloroplatinic acid-vinylsiloxane with a concentration of 5000ppm, and add them to the planetary mixer. Under the conditions of 1000r / min and 5-20r / min revolution, stir at room temperature for 0.5-1h to obtain component A, pack and place it for use; accurately weigh 700g of vinyl silicone oil with a viscosity of 1000mpa.s and a vinyl mass fraction of 0.3%. Add 290g of chain extender with a viscosity of 40cst, 10.2g of crosslinking agent with a viscosity of 65cst, 2.0g of 1-ethynylcyclohexanol, and 0.5g of dibutylhydroxytoluene into the planetary mixer in turn, and at a rotation speed of 200~1000r / min and a revolution speed of 5-20r / min, stir at room temperature for 0.5-1h to obtain component B, which is packaged and placed for use.

[0032] Among them, the terminal vinyl silicone oil is molecularly distilled for 3 hours at...

Embodiment 3

[0037] Accurately weigh 1000g of vinyl-terminated silicone oil with a viscosity of 1000mpa.s and a vinyl mass fraction of 0.30%, and 2.0g of a chloroplatinic acid-vinylsiloxane complex with a concentration of 5000ppm, and add them to the planetary mixer. Under the conditions of 1000r / min and 5-20r / min revolution, stir at room temperature for 0.5-1h to obtain component A, pack and place it for use; accurately weigh 800g of vinyl-terminated silicone oil with a viscosity of 1000mpa.s and a vinyl mass fraction of 0.30%. , 194g of chain extender with a viscosity of 50cst, 6.0g of a crosslinking agent with a viscosity of 65cst, 2.0g of 1-ethynylcyclohexanol, and 0.5g of dibutylhydroxytoluene were added to the planetary mixer in sequence, and the rotation speed was 200~1000r / min, revolution speed 5-20r / min, stirring at room temperature for 0.5-1h, to obtain component B, packaged and placed for use.

[0038] Among them, the terminal vinyl silicone oil is molecularly distilled for 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com