Device and method for recycling thermoset composite by utilizing fluidized bed

A composite material and fluidized bed technology, which is applied in the field of recycling and reuse of waste composite materials, can solve the problems of intermittent production, high energy consumption, high temperature and high pressure, etc., and achieve a large contact area, small performance damage, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

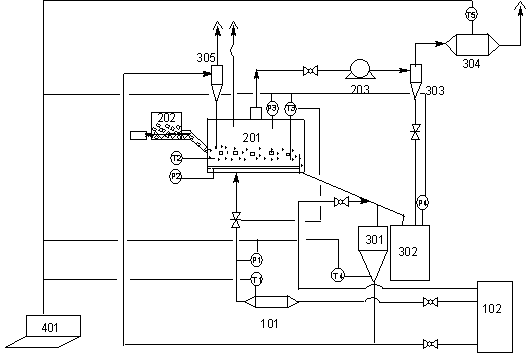

[0032] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Such as figure 1 As shown, the thermosetting composite recovery device of the present invention is provided with an air heater 101, a gas cylinder 102, a horizontal fluidized bed 201, a feeder 202, an induced draft fan 203, a quartz sand circulation storage tank 301, and a recovery fiber storage tank 302 , the second cyclone separator 303, the aftertreatment furnace heater 304, the first cyclone separator 305, the computer and data transmission system 401.

[0034] The fluidized bed used in the present invention is a horizontal fluidized bed 201, which is composed of a fluidized bed box body and a fluidized bed top cover, and a feed inlet and a discharge outlet are respectively arranged at both ends of its length; The feeder 202 is connected; the discharge port is located at one end of the bottom plate of the horizontal fluidized bed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com