Heat treatment equipment for welding seam of numerical control steel weldment

A technology of heat treatment equipment and steel structure, applied in the direction of heat treatment equipment, heat treatment furnace, heat treatment process control, etc., can solve the problems of low efficiency, high labor intensity, high operator requirements, etc., to reduce manufacturing costs, facilitate operation, and ensure comprehensive The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

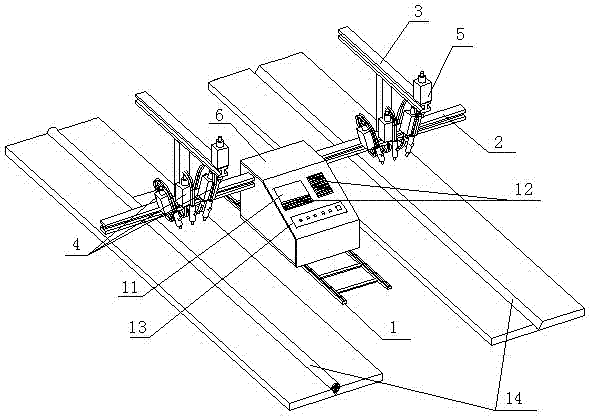

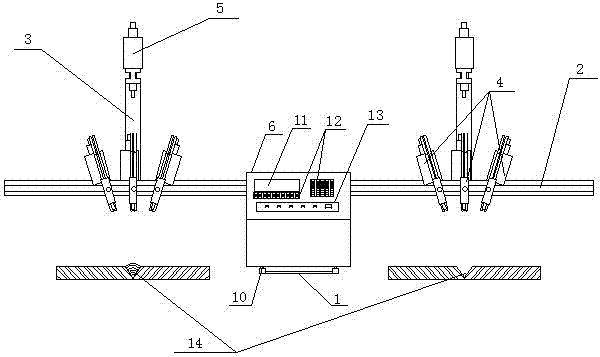

[0016] See figure 1 , figure 2 , numerically controlled steel structure weldment welding seam heat treatment equipment, including a walking track 1, a controller slidingly arranged on the walking track 1, and two adjusting beams connected to the controller;

[0017] Each adjusting crossbeam all comprises a horizontal crossbeam 2 and a T-shaped frame 3 connected to the top of the horizontal crossbeam 2, the horizontal part of the T-shaped frame 3 is perpendicular to the horizontal crossbeam 2, and the horizontal crossbeam 2 is provided with three flame heaters 4, each The nozzles of each flame heater 4 are aimed at the weld seam, and the T-shaped frame 3 horizontal part is provided with an infrared temperature sensing head 5;

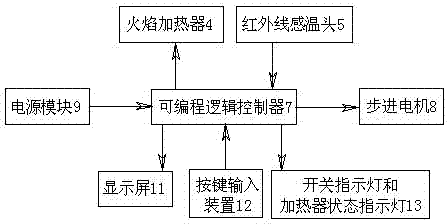

[0018] The controller includes a housing 6, a programmable logic controller 7 arranged inside the housing, a stepper motor 8 and a power module 9 respectively connected to the programmable logic controller 7 arranged inside the housing, and a power mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com