Biomass smelting furnace

A biomass energy and smelting furnace technology, used in furnaces, crucible furnaces, furnace types, etc., can solve the problems of short resistance life, low production capacity, high unit power consumption, etc., to protect the service life and reduce heating costs. , the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

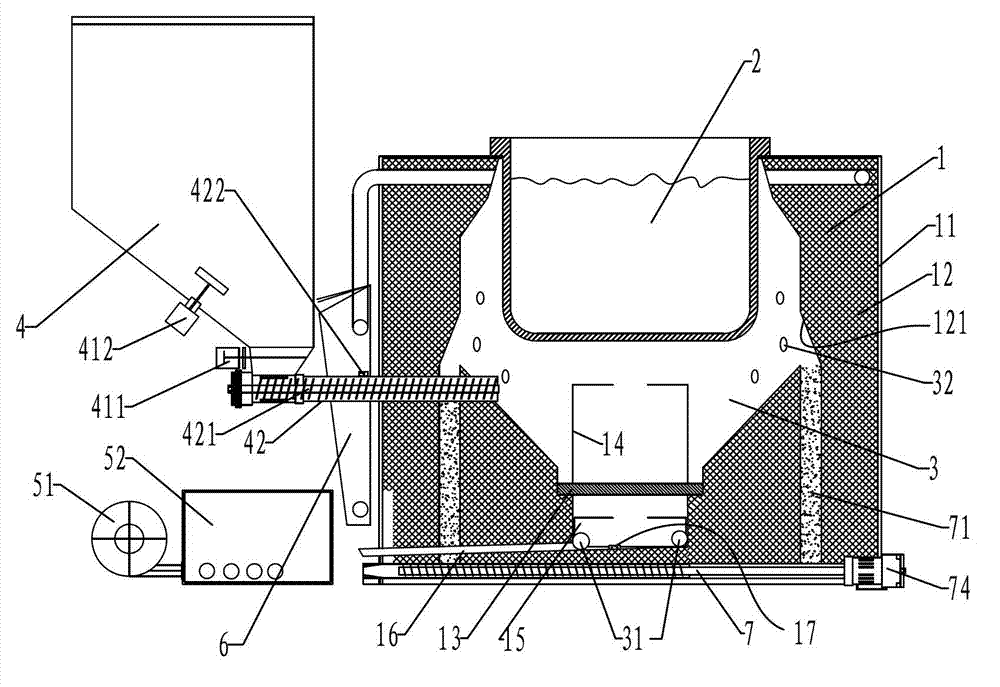

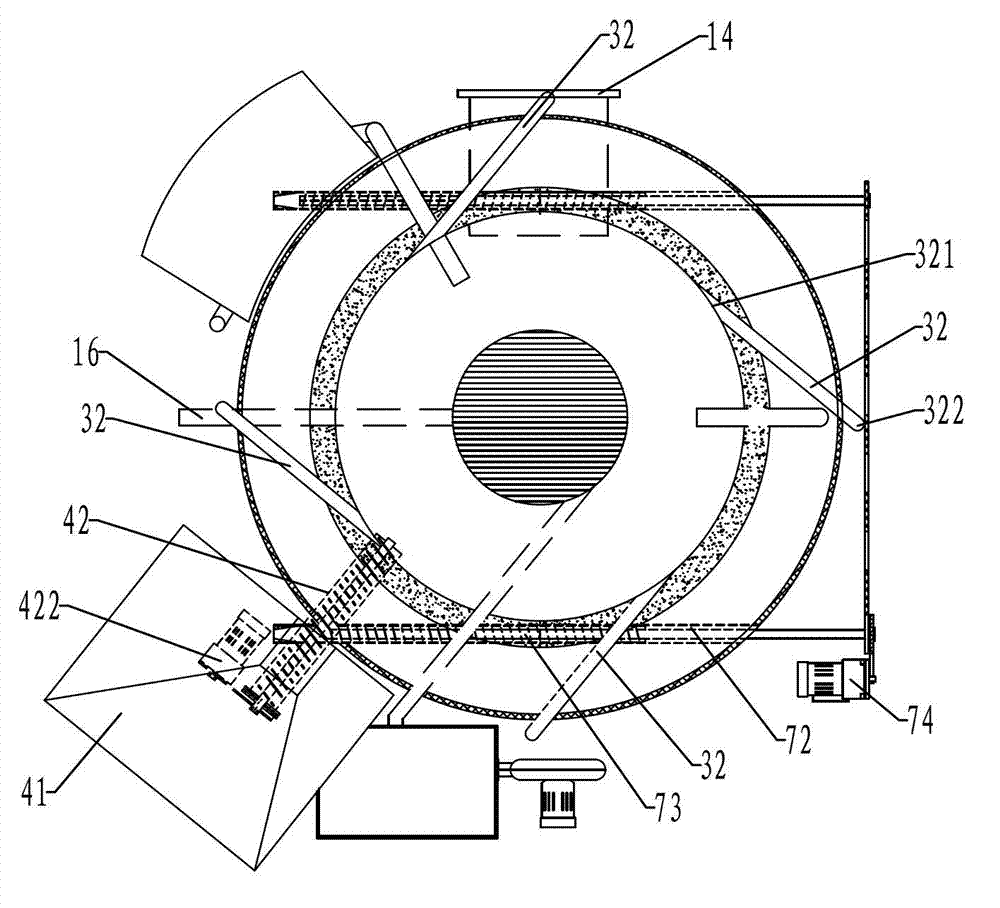

[0026] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

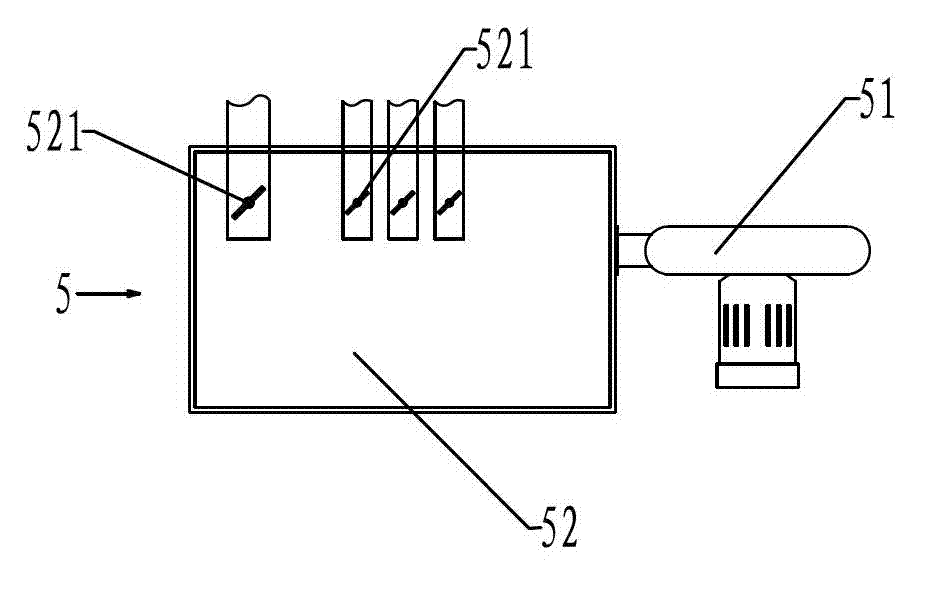

[0027] The biomass energy smelting furnace of this embodiment includes a furnace body 1, a smelting pot 2, a vaporization combustion chamber 3 surrounded by the furnace body, a feeding device 4 for providing biomass energy for the vaporization combustion chamber, an air blast device 5, waste heat The recycling device 6, the automatic ash discharge device 7 and the PLC intelligent control module, and the furnace body is mainly composed of hollow insulating bricks 12 and a shell 11.

[0028] The smelting furnace in this embodiment uses renewable biomass as fuel, and the cost is low. In order to solve the uneven heating caused by the heating of biomass fuel, the furnace body and melting pot will burst, the solution will leak, and the heating speed will be slow. For the problem of low thermal efficiency, the gasification combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com