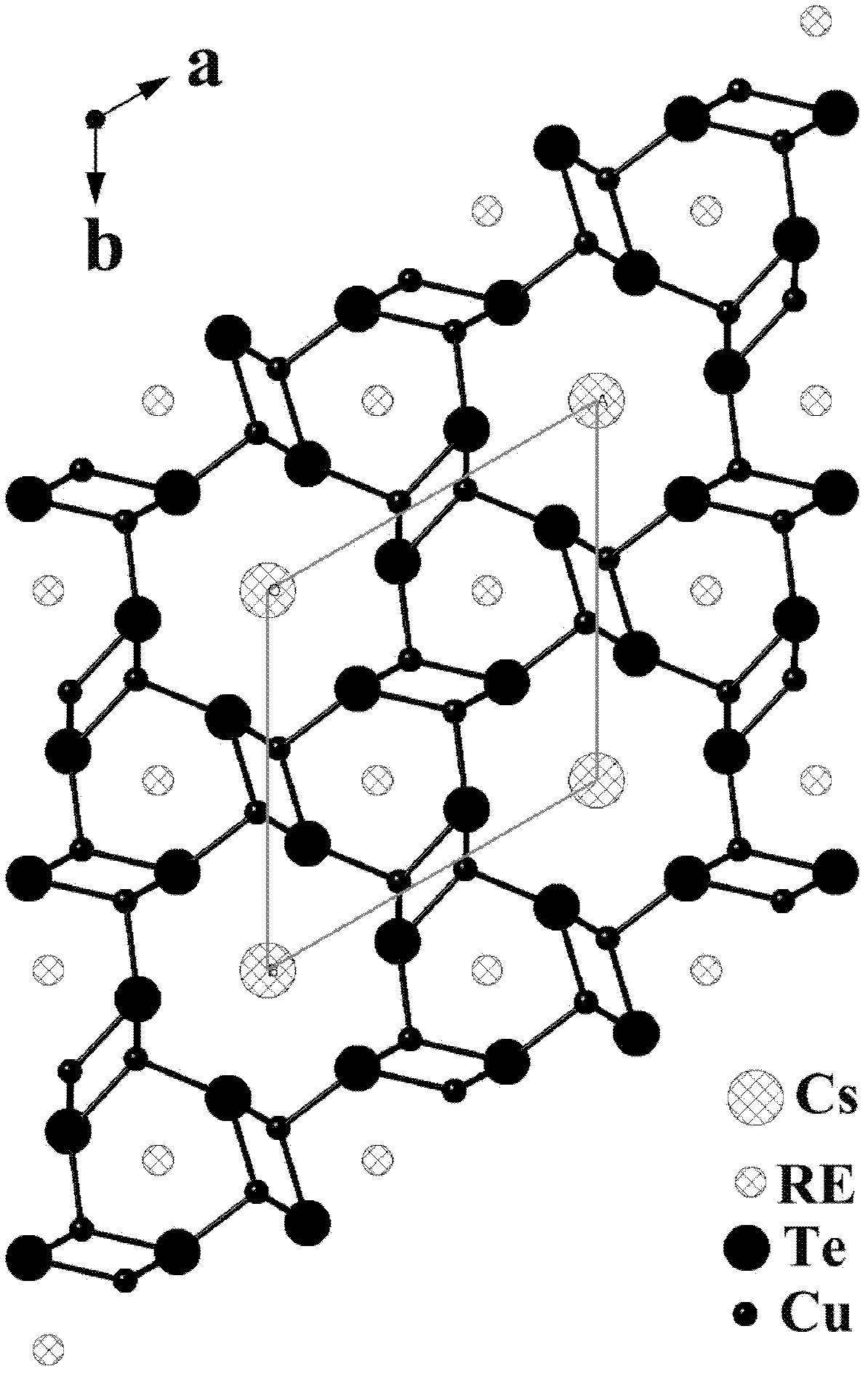

Thermoelectricity material and preparation method thereof

A thermoelectric material and hot spot technology, which is applied in the directions of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

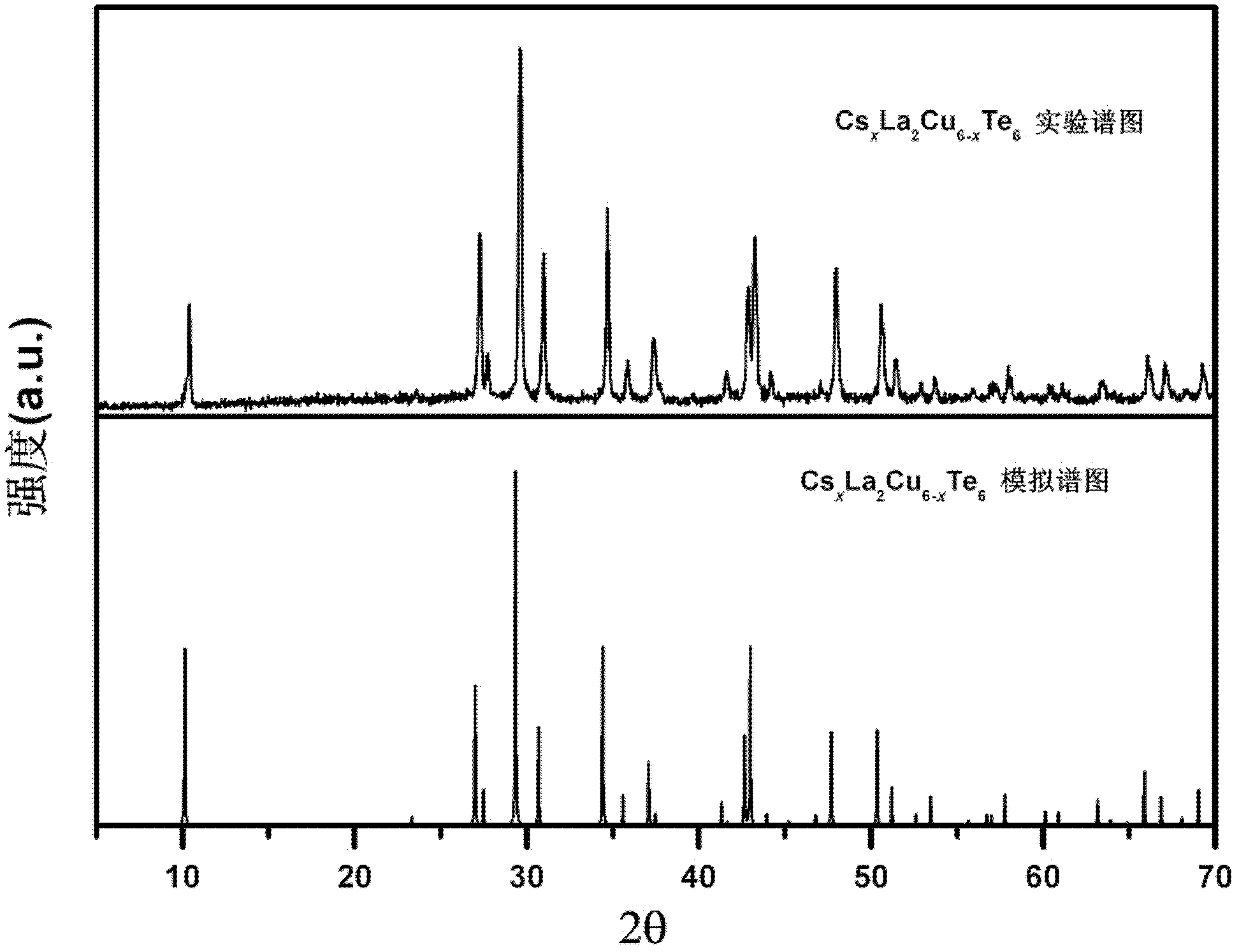

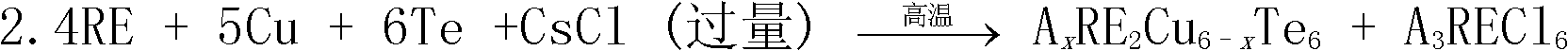

example 1

[0016] In the glove box operation, according to the ratio of the amount of substances CsCl: RE (La, Ce, Pr, Nd): Cu: Te = 3: 2.4: 5: 6, the total weight is about 10 grams, and the load is (φ11×13mm) Quartz tube, and then the quartz tube is melted and sealed under vacuum. Then the reactant is placed in a temperature-programmed tube furnace, and the heating program is as follows: from room temperature to 600°C at a rate of 75°C / hour, then to 950°C at a rate of 12°C / hour, and kept at 950°C for 50 hours, then Decrease to 600°C at a rate of 2°C / hour, close the furnace and allow it to cool naturally. Take out the quartz tube after cooling, and knock off the outer layer of quartz glass to obtain Cs x RE 2 Cu 6-x Te 6 Sinter the bars, crush the bars, wash with distilled water several times to remove CsCl and its Cs 3 RECl 6 After the by-products were removed, they were washed with anhydrous alcohol and then dried to obtain the pure target product.

example 2

[0018] Operated in a glove box, according to the ratio of the amount of substances CsCl: RE (La, Ce, Pr): Cu: Te = 2: 2.4: 5: 6, the total weight is about 18 grams, and put into (φ11×13mm) quartz tube , and then the quartz tube is melted and sealed under vacuum. Then the reactant is vertically placed in a temperature-programmed tube furnace, and the heating program is as follows: from room temperature to 600°C at a rate of 75°C / hour, then to 1000°C at a rate of 12°C / hour, and kept at 1000°C for 50 hours. Then the temperature was lowered to 600° C. at a rate of 10° C. / hour, and the furnace was closed to allow it to cool naturally. Take out the quartz tube after cooling, and knock off the outer layer of quartz glass to obtain Cs x RE 2 Cu 6-x Te 6 Sintered bar, the bottom 4-5mm of the quartz tube is mainly the target product Cs x RE 2 Cu 6-x Te 6 , the top 1mm of the quartz tube is mainly CsCl-Cs 3 RECl 6 eutectic mixture. The bottom 4-5mm sample was polished into a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com