Preparation method of sesame oil

A technology of sesame oil and sesame oil, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of high cost, poor oil quality, low production efficiency, etc., and achieve the effect of improving efficacy, improving economic benefits, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

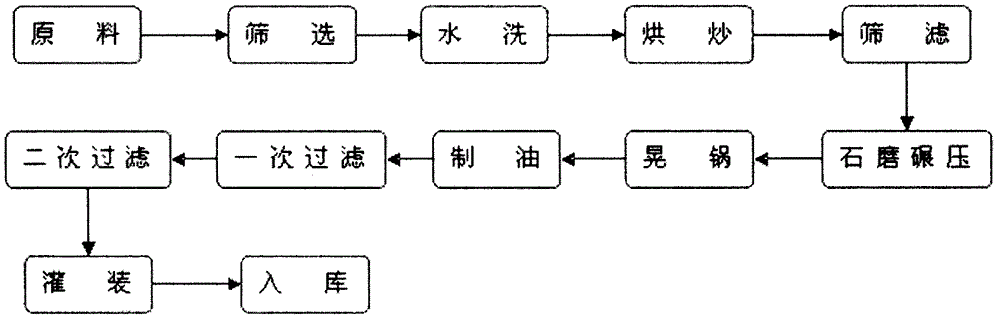

Method used

Image

Examples

Embodiment 1

[0022] After the sesame seeds are screened and washed, they are fried by shaking the pan until they are half mature, and then they are rolled by a stone mill with a speed of 20 rpm. Put these pastes into the shaking pot, add hot water at 90°C for blending, and carry out uninterrupted and regular shaking, keep the shaking speed of the shaking pot at 35 rpm, because the density of sesame oil is small, it is easy to mix with it The impurities are separated and floated on the top, and then the sesame oil is separated from the impurities, and the sesame oil is filtered to remove the impurities and foreign matter in it, then precipitated, filtered, and after two times of filtration, the finished sesame oil is formed and packaged. The sesame oil produced by the above process has an acid value of 1.6mg / g, a peroxide value of 0.1mmol / kg, and aflatoxin B 1 <10ug / kg, does not contain benzo(a)pyrene, does not contain residual solvent, total arsenic (calculated as As) is 0.01mg / kg, lead co...

Embodiment 2

[0024] After the sesame seeds are screened and washed, they are fried by shaking the pot until they are seven mature, and then they are rolled by a stone mill with a speed of 25 rpm. Put these pastes into the shaking pot, add hot water at 85°C for blending, and carry out uninterrupted and regular shaking, keep the shaking speed of the shaking pot at 30 rpm, because the density of sesame oil is small, it is easy to mix with it The impurities are separated and floated on the top, and then the sesame oil is separated from the impurities, and the sesame oil is filtered to remove the impurities and foreign matter in it, then precipitated, filtered, and after two times of filtration, the finished sesame oil is formed and packaged. The sesame oil produced by the above process has an acid value of 1.6mg / g, a peroxide value of 0.1mmol / kg, and aflatoxin B 1 <10ug / kg, does not contain benzo(a)pyrene, does not contain residual solvent, total arsenic (calculated as As) is 0.01mg / kg, lead c...

Embodiment 3

[0026] After the sesame seeds are screened and washed, they are fried by shaking the pot until they are seven mature, and then they are rolled by a stone mill with a speed of 20 rpm. Put these pastes into the shaking pot, add 80°C hot water for blending, and carry out regular shaking without interruption, keep the shaking speed of the shaking pot at 35 rpm, because the density of sesame oil is small, it is easy to mix with it The impurities are separated and floated on the top, and then the sesame oil is separated from the impurities, and the sesame oil is filtered to remove the impurities and foreign matter in it, then precipitated, filtered, and after two times of filtration, the finished sesame oil is formed and packaged. The sesame oil produced by the above process has an acid value of 1.6mg / g, a peroxide value of 0.1mmol / kg, and aflatoxin B 1 <10ug / kg, does not contain benzo(a)pyrene, does not contain residual solvent, total arsenic (calculated as As) is 0.01mg / kg, lead c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com