Quick-frozen sweet potato conditioning product with roasted sweet potato flavor and processing method thereof

A processing method and technology for roasting sweet potatoes, applied in the directions of food preparation, application, food science, etc., can solve the problems of inability to adjust the nutrition and flavor of sweet potatoes, low yield, inability to improve nutrition and flavor, etc. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

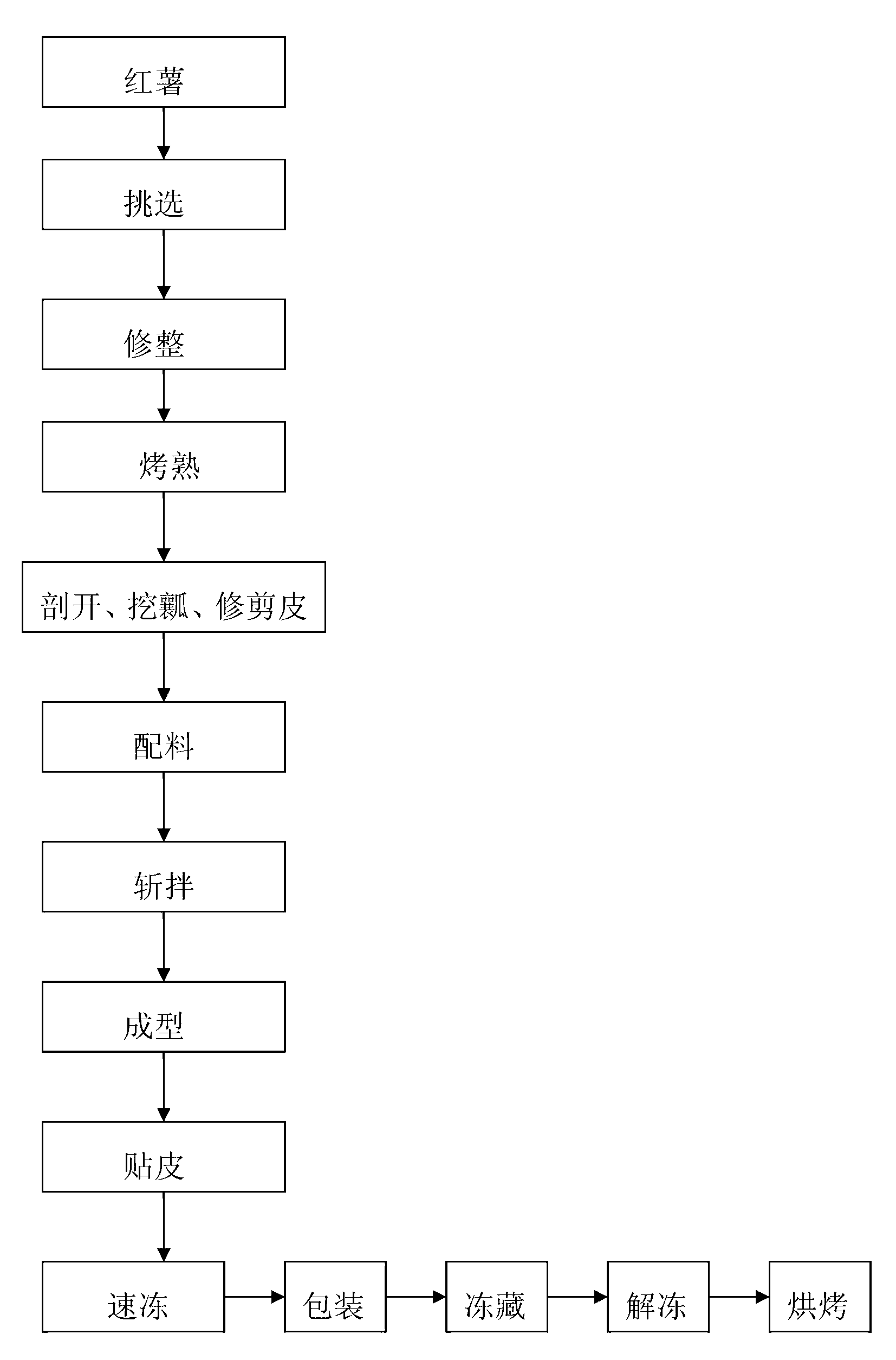

Image

Examples

Embodiment 1

[0050] A. Selection: manual selection of sweet potatoes suitable for roasting and processing, removing rotten and sweet potatoes with a diameter of less than 3cm;

[0051] B. Cleaning: Use a fruit and vegetable cleaning machine with a cleaning brush to clean the selected sweet potatoes for 2 minutes;

[0052] C. Trimming: Manually use a trimming knife to trim and clean the spots and rotten spots on the skin of the sweet potato, remove the root hairs, and remove the two ends of the sweet potato;

[0053] D. Roasting: Put the trimmed sweet potatoes into a roaster with a power of 3KW, and bake for 0.5 hours at a temperature of 160°C;

[0054] E. Cut open, dig out the flesh, and trim the skin: cut the cooked sweet potato from the middle with a knife, dig out the sweet potato meat, and put it in a clean container for later use; and trim the sweet potato skin from which the sweet potato meat has been removed shape (use a certain mold to trim out a certain shape when trimming the swee...

Embodiment 2

[0065] A. Selection: manual selection of sweet potatoes suitable for roasting and processing, removing rotten and sweet potatoes with a diameter of less than 3cm;

[0066] B. Cleaning: Use a fruit and vegetable cleaning machine with a cleaning brush to clean the selected sweet potatoes for 2.5 minutes;

[0067] C. Trimming: Manually use a trimming knife to trim and clean the spots and rotten spots on the skin of the sweet potato, remove the root hairs, and remove the two ends of the sweet potato;

[0068] D. Roasting: Put the trimmed sweet potatoes into a roaster with a power of 4KW, and bake at a temperature of 220°C for 0.75 hours;

[0069] E. Cut open, dig out the flesh, and trim the skin: cut the cooked sweet potato from the middle with a knife, dig out the sweet potato meat, and put it in a clean container for later use; and trim the sweet potato skin from which the sweet potato meat has been removed shape;

[0070] F. Ingredients: weighed according to the mass percenta...

Embodiment 3

[0080] A. Selection: manual selection of sweet potatoes suitable for roasting and processing, removing rotten and sweet potatoes with a diameter of less than 3cm;

[0081] B. Cleaning: Use a fruit and vegetable cleaning machine with a cleaning brush to clean the selected sweet potatoes for 5 minutes;

[0082] C. Trimming: Manually use a trimming knife to trim and clean the spots and rotten spots on the skin of the sweet potato, remove the root hairs, and remove the two ends of the sweet potato;

[0083] D. Roasting: Put the trimmed sweet potatoes into a roaster with a power of 5KW, and bake for 2 hours at a temperature of 280°C;

[0084] E. Cut open, dig out the flesh, and trim the skin: cut the cooked sweet potato from the middle with a knife, dig out the sweet potato meat, and put it in a clean container for later use; and trim the sweet potato skin from which the sweet potato meat has been removed shape;

[0085] F. Ingredients: weighed according to the mass percentage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com