Visible light responsive composite photocatalyst and its preparation method and use

A visible light and composite light technology, applied in the field of photocatalysis, can solve the problems of different catalyst reduction performance and photocatalytic oxidation performance, expensive catalyst preparation cost, low solar energy utilization rate, etc., to achieve a wide range of applications, high cost performance, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

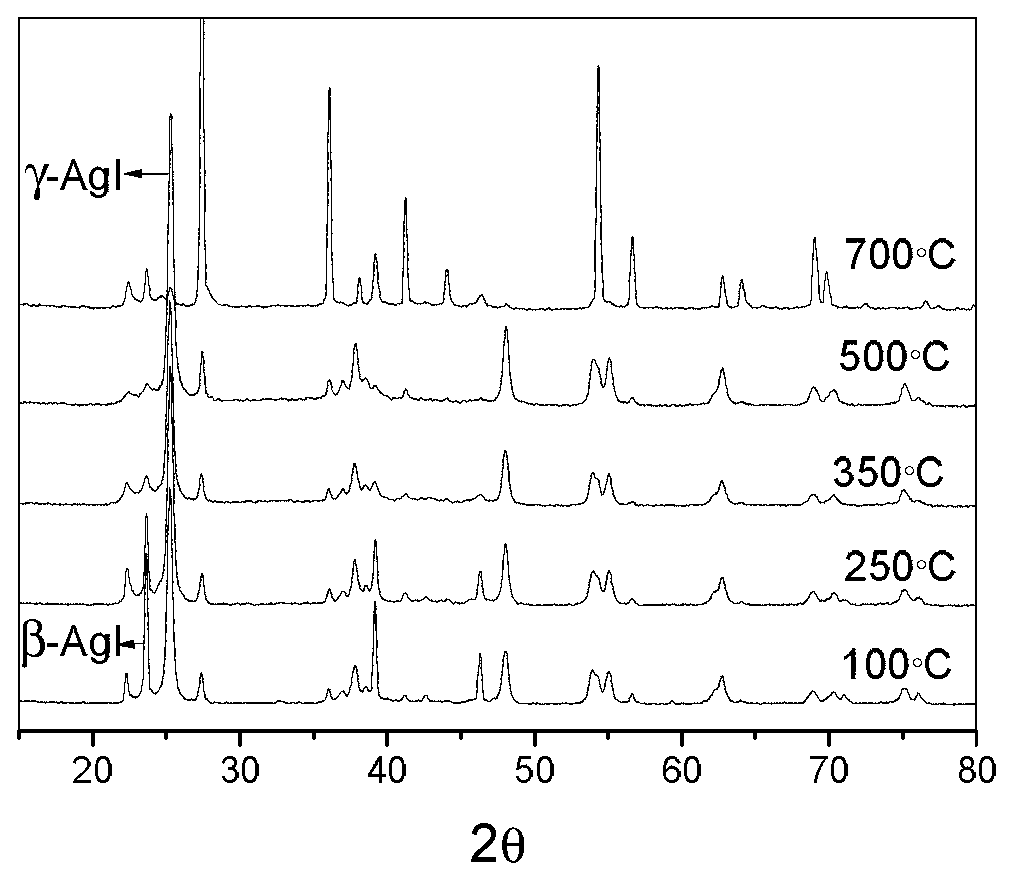

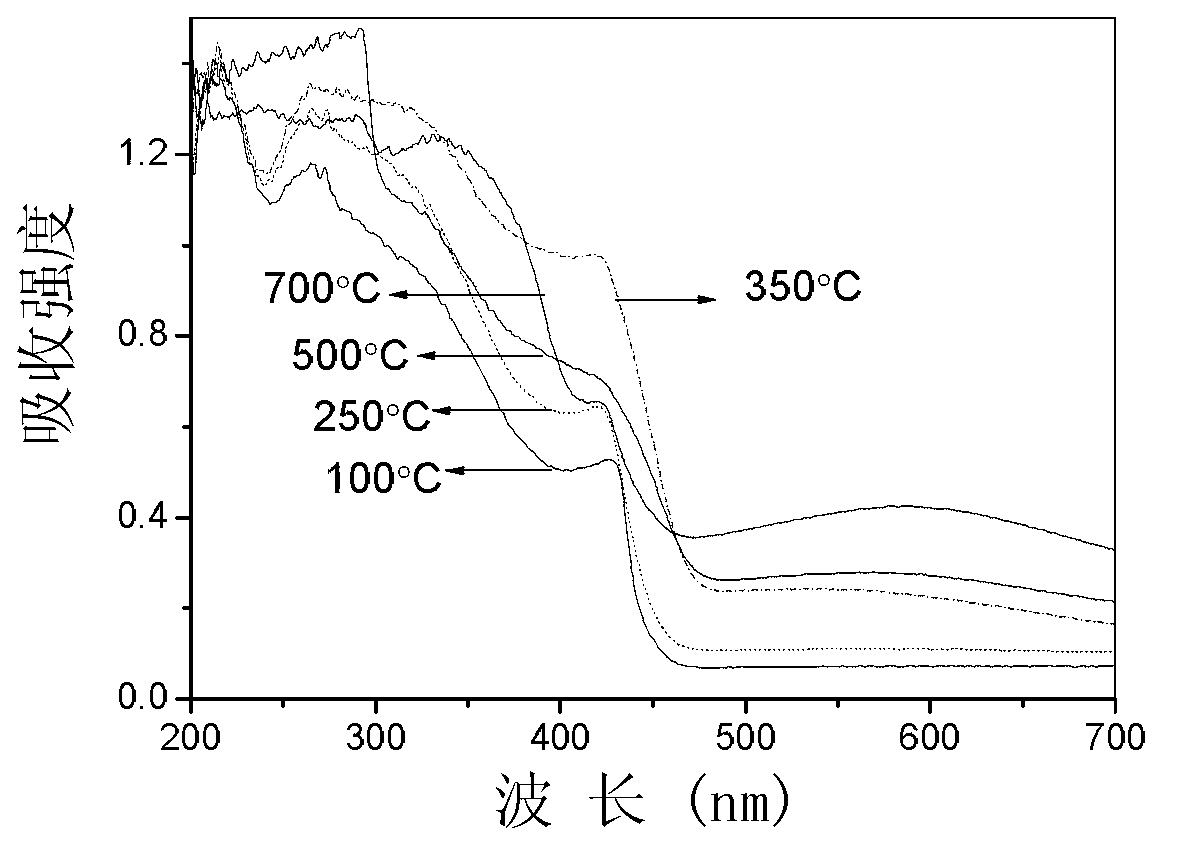

[0040] Accurately weigh 1.000g of commercial P25 TiO 2 and 0.1025g KI, dispersed in 100mL deionized water, ultrasonically dispersed for 10 minutes. Slowly add AgNO dropwise under magnetic stirring 3 Silver ammonia solution (AgNO 3 : KI molar ratio is 1: 1), stirred for 1 hour, and a bright yellow milky precipitate was obtained. Then filter and dry at 100°C in a blast drying oven to obtain AgI / TiO containing AgI of 5% (molar ratio) 2 . The prepared 5%AgI / TiO 2 Calcined at 250°C, 350°C, 500°C and 700°C for 2 hours to obtain AgI / TiO after heat treatment at different temperatures 2 composite photocatalyst.

[0041] AgI / TiO heat-treated at different temperatures 2 Carry out X-ray diffraction characterization, the specific results are shown in figure 1 , it can be seen from the figure that with the increase of the catalyst preparation temperature, the proportion of β-AgI is greatly increased, and the AgI / TiO prepared at low temperature 2 Coexist in two phases of β-AgI and γ...

Embodiment 2

[0045] Accurately weigh 1.000g of commercial P25 TiO 2 and different quality KI, control KI and TiO 2 The molar ratio is between 1% and 15%. Disperse it in 100mL deionized water and ultrasonically disperse for 10 minutes. Slowly drop a certain concentration of AgNO under magnetic stirring 3 Silver ammonia solution (AgNO 3 : KI molar ratio is 1: 1), stirred for 1 hour, obtained light yellow to bright yellow milky precipitate. Then filter, dry at 100°C in a blast drying oven, and then calcinate at 350°C in a muffle furnace for 2 hours to obtain β-AgI / TiO containing 1% to 15% (molar ratio) AgI 2 -350.

[0046] Accurately weigh 1.000g of commercial P25 TiO 2 And different quality KI, KBr, control K 总 with TiO 2 The molar ratio of KI to KBr is 0.05:1, and the molar ratio of KI to KBr is between 0.11 and 1.50. It is dispersed in 100 mL of deionized water and ultrasonically dispersed for 10 minutes. Slowly drop a certain concentration of AgNO under magnetic stirring 3 Silver...

Embodiment 3

[0048] Add 50mL and 0.5mL of simulated hexavalent chromium-containing wastewater containing potassium dichromate concentration of 20mg / L (calculated by chromium mass) into six glass reactors, respectively. -4 mol / L EDTA, add 50 mg (100°C, 250°C, 350°C, 500°C, 700°C) calcined AgI / TiO 2 Visible light photocatalyst (prepared in Example 1), use perchloric acid to adjust the pH value of the simulated wastewater containing hexavalent chromium to 2, magnetically stir and disperse the catalyst in the dark for 30min, the artificial light source used is a 50W xenon lamp, and configure a 420nm cut-off filter film, turn on the light source and irradiate with weak visible light for 60 minutes.

[0049] Under the irradiation of weak visible light, AgI with excellent visible light response and TiO with electron transport properties 2 Composite made AgI / TiO 2 Reduction of hexavalent chromium Cr(VI) which is soluble, easy to migrate and highly toxic in water to trivalent chromium Cr(III) whi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap