Equipment and technology of calcium oxide producing with calcium sulfate

A technology of calcium oxide and calcium sulfate, which is applied in the fields of calcium/strontium/barium oxide/hydroxide, chemical industry, sustainable manufacturing/processing, etc. It can solve the problems of affecting the reaction rate and waste heat waste at low temperature of equipment, etc., and achieves reduction Effects of energy consumption, efficient recycling, and waste avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

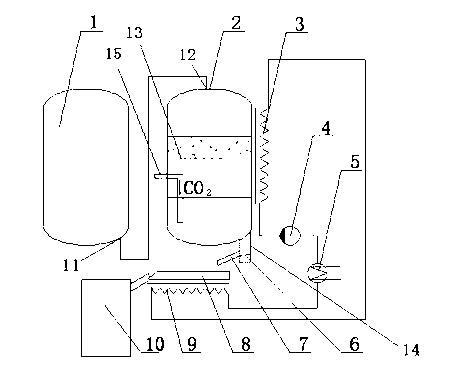

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] The equipment for producing calcium oxide with calcium sulfate of the present embodiment comprises a calcining kiln 1, a digestion chamber 2, and a secondary calcining kiln 10, and the calcining kiln 1 communicates with the feed inlet 12 at the top of the digestion chamber 2 through the bottom outlet I11, The digestion chamber 2 is divided into two layers, separated by a 3000-mesh filter I13 in the middle; the side wall of the digestion chamber 2 is also provided with a carbon dioxide inlet pipe 15 leading to the bottom of the digestion chamber 2, and the bottom of the digestion chamber 2 is provided with a filter. II6 and the outlet II14 of the separation bucket 7, the filter screen II6 is an inclined structure, and the angle with the horizontal line is 45 degrees, the lower end of the filter screen II6 is equal to the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com