Preparation method of manganous-manganic oxide

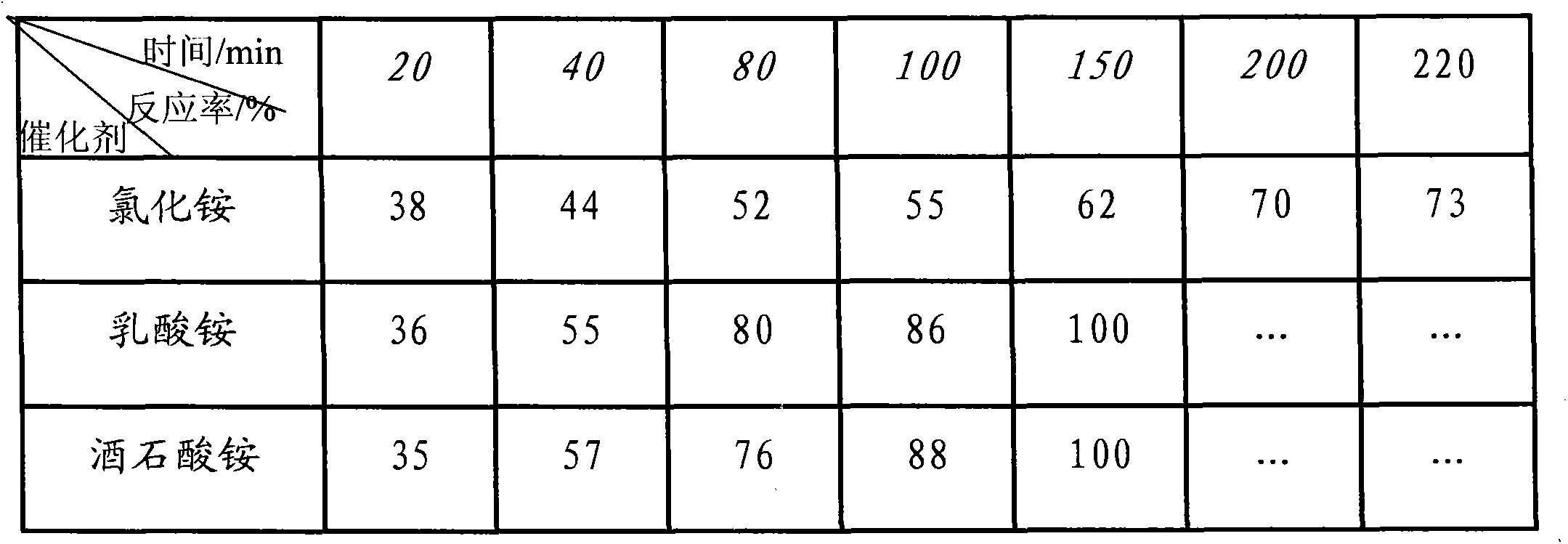

A technology of manganese tetroxide and manganese powder, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of slow manganese hydrolysis, influence of purity, chlorine and sulfur residues, etc., to accelerate the hydrolysis reaction, accelerate the complexation, shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

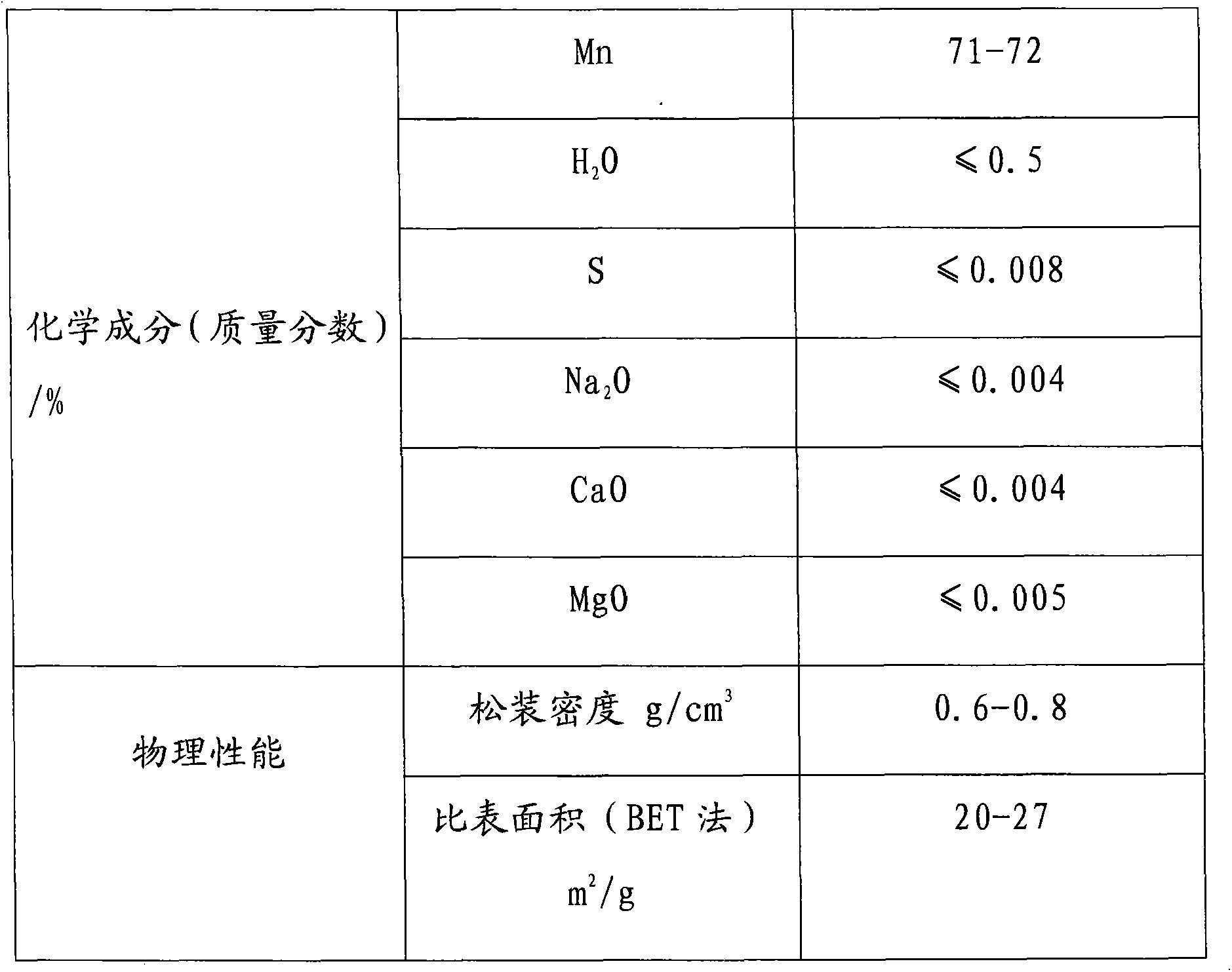

Embodiment 1

[0033] Example 1: The first step reaction conditions: take manganese powder with particle size less than 50 μm, ammonium lactate concentration 10g / L, temperature 40°C, stirring speed 300rpm / min, react for 5h, all manganese hydroxides are generated; the second step Reaction conditions: At a temperature of 60°C, a sufficient amount of air is introduced to oxidize, the stirring speed is 300rpm / min, and the reaction is completed in 4 hours. After washing and drying, trimanganese tetraoxide is obtained. The product index is: the manganese content is 71.6%, Na 2 O0.0045%, CaO0.0025%, MgO0.0045%, S0.007%, the specific surface area measured by BET method is 25.4m 2 / g; after adding 10-20% of the amount of ammonium ortholactate to the above-mentioned filtrate, it can be recycled.

Embodiment 2

[0034] Example 2: The first step reaction conditions: take manganese powder with a particle size of less than 50 μm, the concentration of ammonium succinate is 20g / L, the temperature is 50°C, the stirring speed is 400rpm / min, and the reaction is 6h, all of which are precursors of trimanganese tetraoxide body; the second step reaction conditions: at a temperature of 50°C, pass in a sufficient amount of air to oxidize, the air is dispersed into small bubbles through the air distributor, the stirring speed is 400rpm / min, the reaction is completed for 6h, and the trimanganese tetraoxide is obtained after washing and drying , its product index is: manganese content is 71.8%, Na 2 O0.0048%, CaO0.0035%, MgO0.0044%, S0.006%, the specific surface area measured by BET method is 26.5m 2 / g; the above-mentioned filtrate is recycled after adding 10-20% of the amount of ammonium orthosuccinate.

Embodiment 3

[0035] Example 3: Take manganese powder with a particle size of less than 50 μm, ammonium lactate concentration 20g / L, temperature 30°C, stirring speed 300rpm / min, react for 3h, and all produce trimanganese tetraoxide precursors; the second step reaction conditions: at temperature At 70°C, a sufficient amount of air is introduced to oxidize, the air is diffused into small bubbles through the air distributor, the stirring speed is 500rpm / min, and the reaction is completed in 4.5h. After washing and drying, trimanganese tetraoxide is obtained. The product index is: the manganese content is 71.9%, Na 2 00.0040%, CaO0.0046%, MgO0.0033%, S0.006%, the specific surface area measured by BET method is 24.8m 2 / g; after adding 10-20% of the amount of ammonium ortholactate to the above-mentioned filtrate, it can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com