Device and technology employed to hydrogen peroxide purification

A hydrogen peroxide and process technology, applied in the field of equipment and process, can solve the problems of resin clogging and high energy consumption, and achieve the effect of improving quality, high degree of automation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

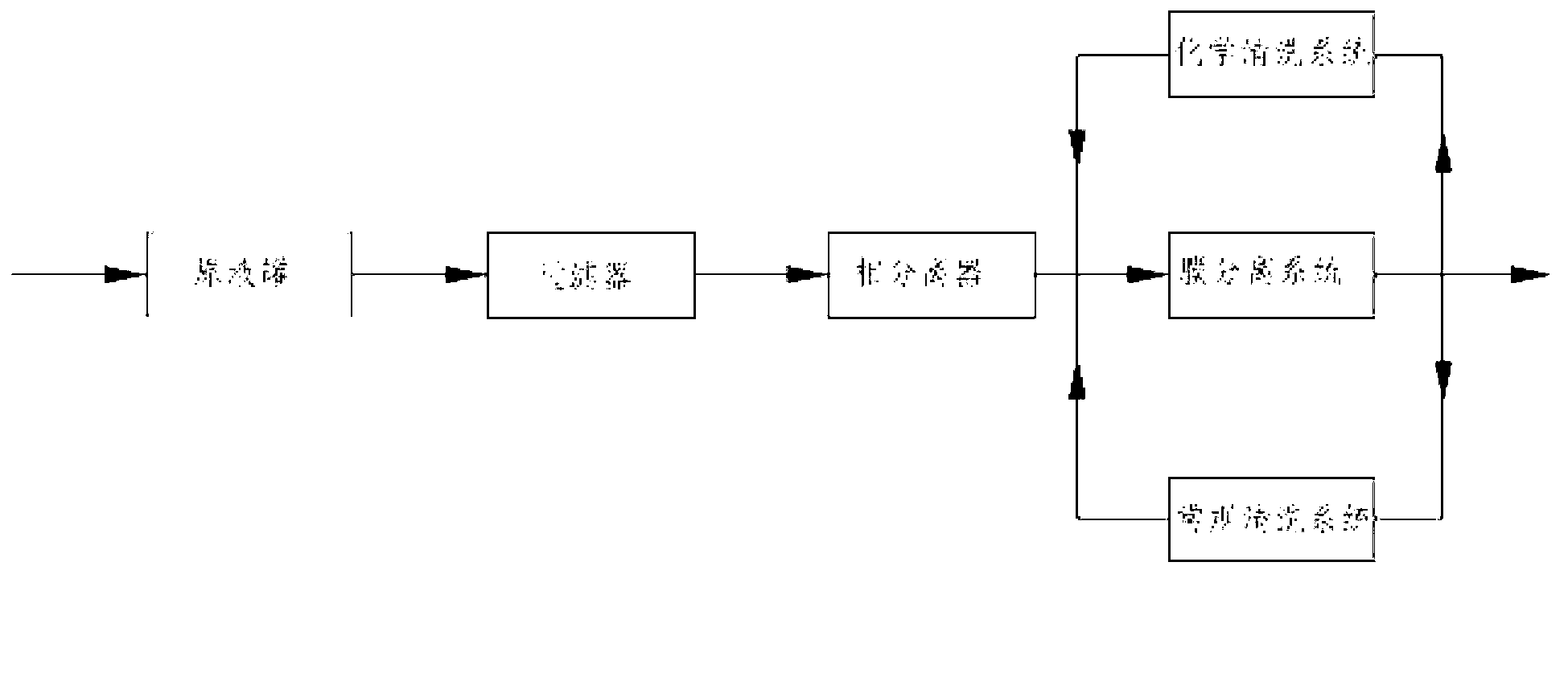

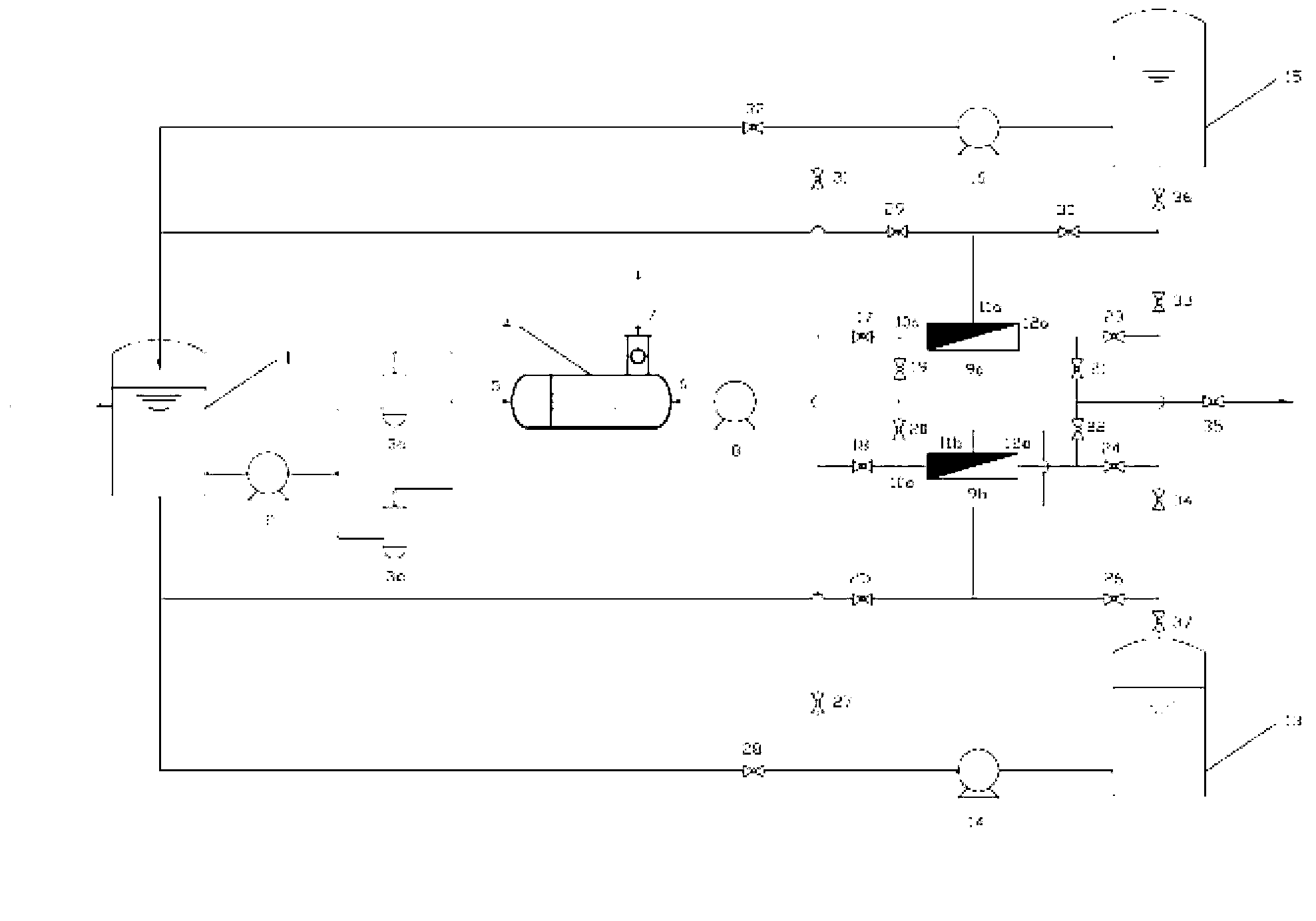

[0031] figure 1 It is a block diagram of a device and a process flow for purifying hydrogen peroxide according to the present invention. Such as figure 1 As shown: the process provided by the present invention is completed by the following steps: (a) industrial-grade hydrogen peroxide enters the raw liquid tank first; (b) the mixed liquid in the raw liquid tank enters the filter after being pressurized by the pump for pretreatment; (c) after pretreatment The hydrogen peroxide enters the phase separator to separate the undissolved organic phase and the hydrogen peroxide. After separation, the light phase organic matter is discharged from the system, and the hydrogen peroxide solution of the heavy phase saturated organic matter enters the subsequent membrane separation system; (d) In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com