Method for preparing polyurethane rubber granule mixture for pavement self-stress icebreaking

A technology of polyurethane rubber and mixture, which is applied in the field of rubber mixture, which can solve the problems of ice cracking, snow freezing on the road, and poor road performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

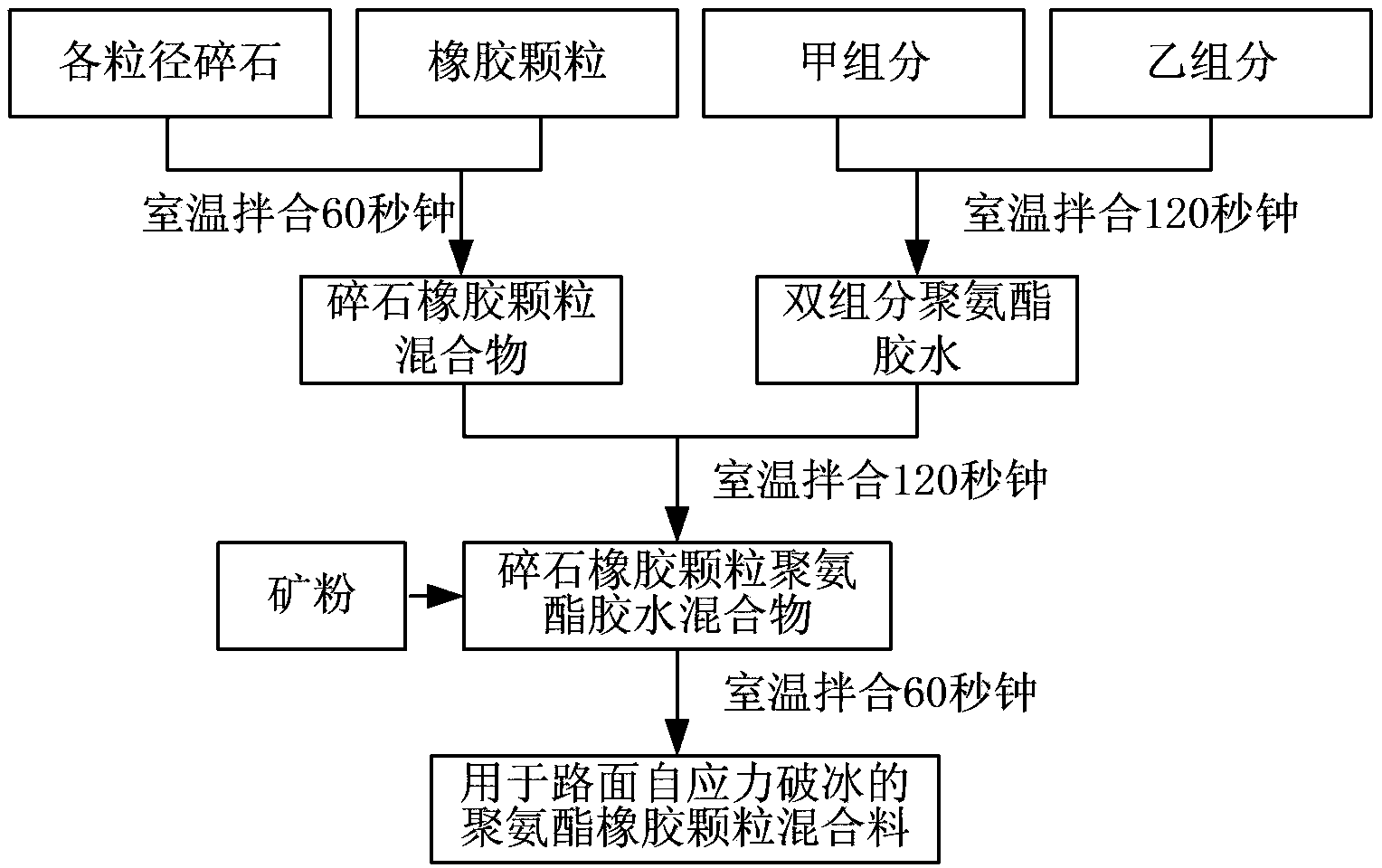

Method used

Image

Examples

Embodiment 1

[0084] The first step is to prepare two-component polyurethane glue

[0085] Ⅰ. Preparation of A component

[0086] The raw materials for preparing component A are shown in the table below,

[0087] raw material

Pure MDI

Liquefied MDI

Polyether diol

95

5

60

[0088] MDI in the above table is the abbreviation of diphenylmethane diisocyanate, the same below,

[0089] Dehydrate the polyether diol at 100°C and a vacuum of 0.08MPa for 1 hour to constant weight. After cooling to 40°C, add the melted measured pure MDI and liquefied MDI, and react at 75°C for 2 hours , analysis of the NCO content of the prepolymer reaches 12% that meets the requirements, thus obtaining the first component,

[0090] Ⅱ. Preparation of component B

[0091] The raw materials for preparing component B are shown in the table below,

[0092]

[0093] The composite polyether in the above table is prepared by adjusting the mass ratio, trihyd...

Embodiment 2

[0106] The first step is to prepare two-component polyurethane glue

[0107] Ⅰ. Preparation of A component

[0108] The raw materials for preparing component A are shown in the table below,

[0109] raw material

Pure MDI

Liquefied MDI

polyether triol

95

5

80

[0110] MDI in the above table is the abbreviation of diphenylmethane diisocyanate, the same below,

[0111] Dehydrate the polyether triol at 105°C and a vacuum of 0.08MPa for 1 hour to constant weight, cool to 45°C, then add the melted measured pure MDI and liquefied MDI, react at 78°C for 2.5 hours , analysis of the NCO content of the prepolymer reaches 12% that meets the requirements, thus obtaining the first component,

[0112] Ⅱ. Preparation of component B

[0113] The raw materials for preparing component B are shown in the table below,

[0114]

[0115] The composite polyether in the above table is prepared by adjusting the mass ratio, trihydroxy...

Embodiment 3

[0128] The first step is to prepare two-component polyurethane glue

[0129] Ⅰ. Preparation of A component

[0130] The raw materials for preparing component A are shown in the table below,

[0131] raw material

Pure MDI

Liquefied MDI

Polyether diol

95

5

100

[0132] MDI in the above table is the abbreviation of diphenylmethane diisocyanate, the same below,

[0133] Dehydrate the polyether diol at 110°C and a vacuum of 0.08MPa for 1 hour to constant weight. After cooling to 50°C, add the melted measured pure MDI and liquefied MDI, and react at 80°C for 3 hours , analysis of the NCO content of the prepolymer reaches 12% that meets the requirements, thus obtaining the first component,

[0134] Ⅱ. Preparation of component B

[0135] The raw materials for preparing component B are shown in the table below,

[0136]

[0137] The composite polyether in the above table is prepared by adjusting the mass ratio, trihy...

PUM

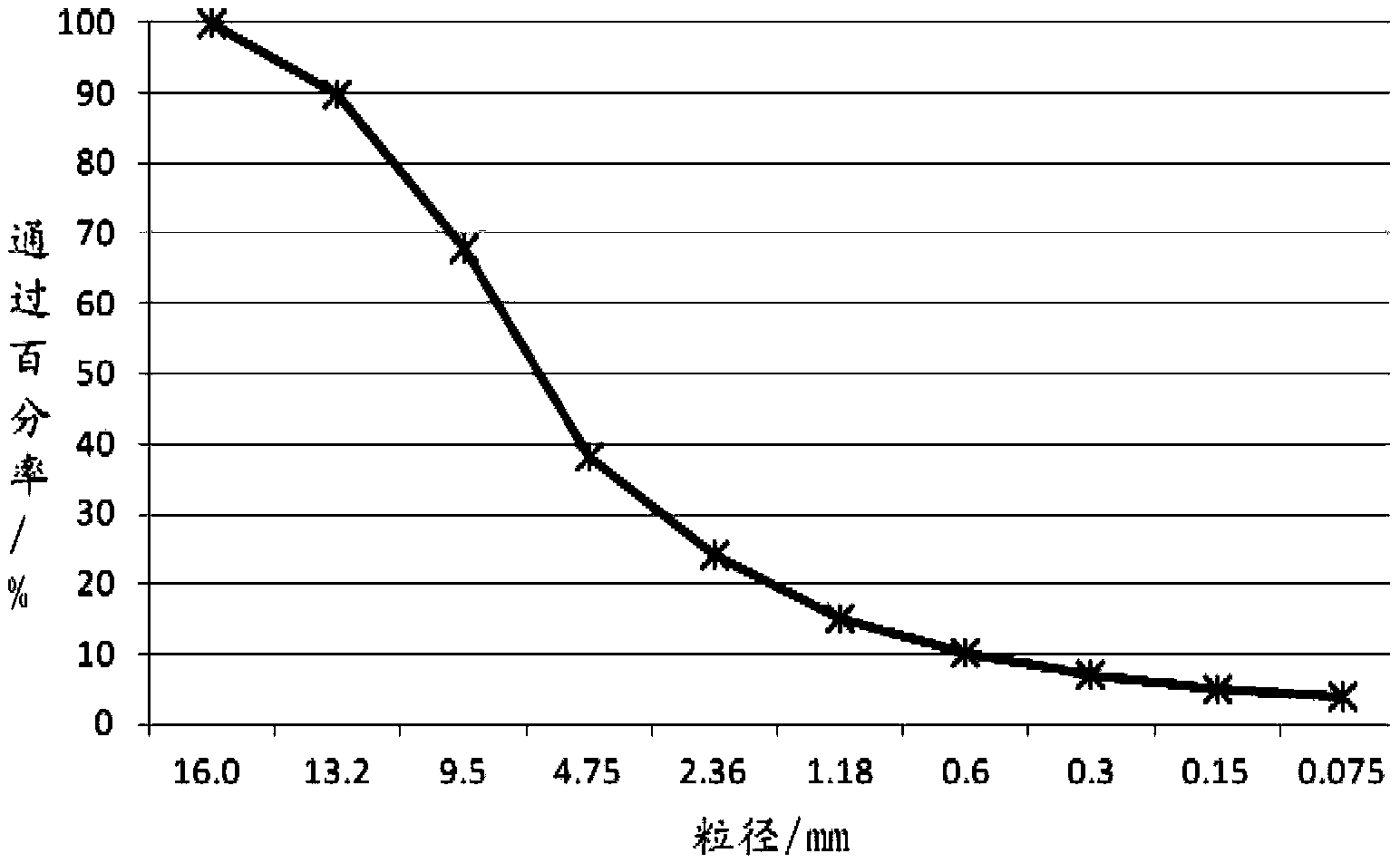

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com