Ethoprophos product and method for preparing ethoprophos

A technology of profenaphos and its products, which is applied in the field of pesticides, can solve the problems of low purity, strong odor, and large environmental pollution, and achieves the effects of simple process operation and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

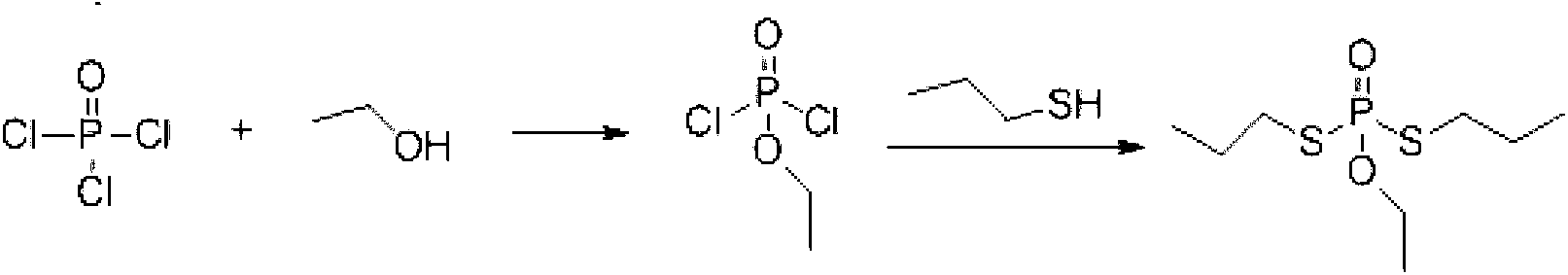

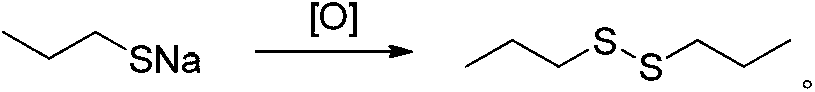

Method used

Image

Examples

Embodiment 1

[0035] Put 600g of phosphorus oxychloride into a 1000ml three-necked reaction bottle, install a stirring, rectifying tower, dropping funnel, and thermometer, then lower the temperature to below 2 degrees Celsius, and slowly add 100g dropwise under slight negative pressure and vigorous stirring Absolute ethanol, control the reaction temperature below 3 degrees Celsius. After the ethanol was added dropwise, the insulation was continued for 12 hours, and after rectification and recovery of phosphorus oxychloride, 336 g of dichloro compounds with a content of more than 99% by weight were obtained at a temperature not higher than 100 degrees Celsius.

Embodiment 2

[0037] Put 600g of phosphorus oxychloride into a 1000ml three-necked reaction bottle, install a stirring, rectifying tower, dropping funnel, and thermometer, then lower the temperature to below 0 degrees Celsius, and slowly add 100g dropwise under slight negative pressure and vigorous stirring Absolute ethanol, control the reaction temperature below 10 degrees Celsius. After the ethanol was added dropwise, the insulation was continued for 6 hours, and after phosphorus oxychloride was recovered by rectification, 317g of dichloro compounds with a content of more than 99% by weight were obtained at a temperature not higher than 80 degrees Celsius.

Embodiment 3

[0039] After adding 60ml of toluene into a 250ml three-necked bottle, add 7g of sodium hydroxide and 0.38g of additives in turn, raise the temperature to 65 degrees Celsius, slowly add 25g of propanethiol dropwise, keep warm for three hours, then lower the temperature to 0~5 degrees Celsius, dropwise add Dichloro compound 10g, naturally warming up to room temperature, insulation for 5 hours. After adding 5% hydrochloric acid aqueous solution to adjust the pH to 6, after stirring for 30 minutes, the water layer was separated, and the organic layer was washed to neutral with water. The solvent was removed under vacuum. Obtained 14 g of protonphos products with a small amount of remaining propanethiol, the content of which was greater than 98% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com