Bidirectional stretching polypropylene film for hot binding compounding, and its preparation method

A biaxially stretched film and polypropylene technology, applied in the direction of film/sheet adhesive, adhesive type, grafted polymer adhesive, etc., can solve the problem of low laminating speed and achieve the goal of overcoming two The effects of secondary processing, high stiffness, and excellent thermal lamination performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

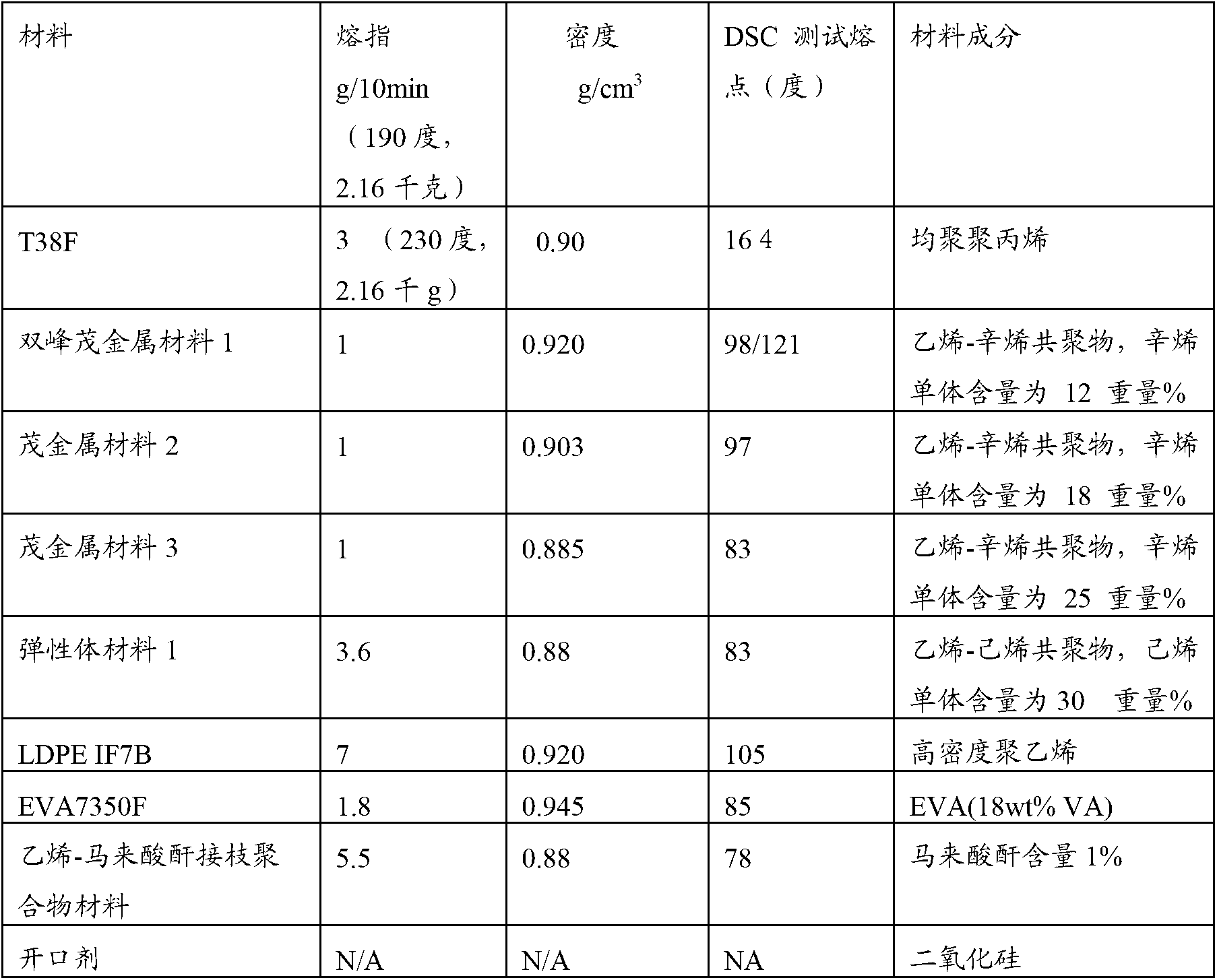

[0081] The 20-micron BOPP thermal lamination protective film is produced on a 5-layer co-extruded double-bubble biaxial stretching equipment, and its structure is shown in the table below.

[0082]

[0083] Processing technology and parameters

[0084]

[0085] The functional layer of the polypropylene biaxially oriented film of Example 1 is measured by differential scanning calorimetry (DSC), and the melting peak area on the DSC curve with a melting point lower than 90 degrees accounts for about 90% of the total area of the DSC curve.

Embodiment 2

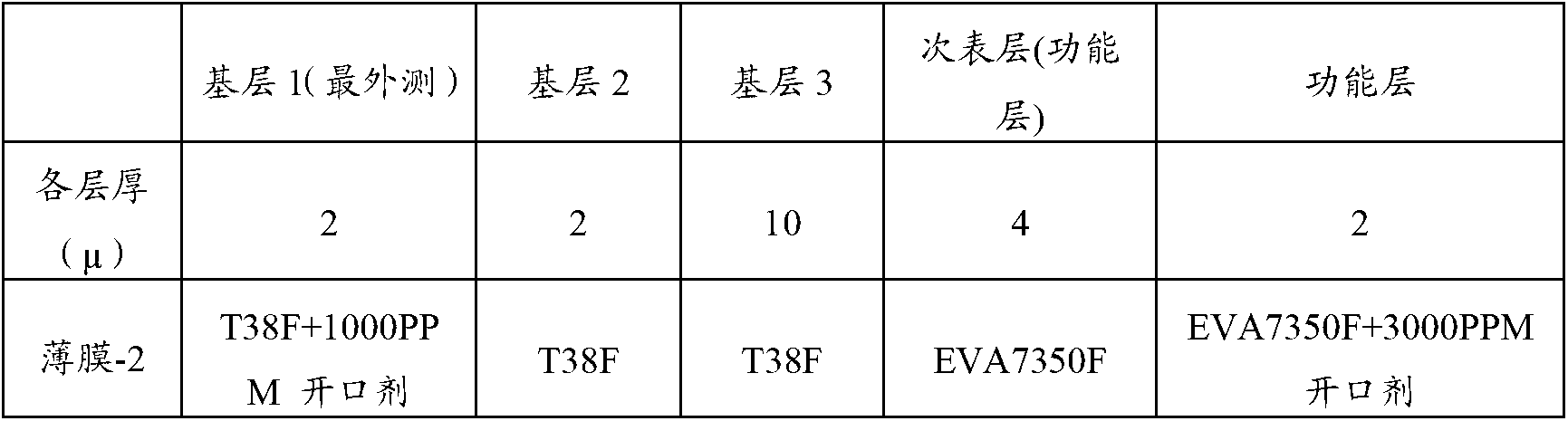

[0087] A 20-micron BOPP thermal lamination protective film is produced on a 5-layer co-extrusion double bubble process (Double Bubble Process) biaxial stretching equipment, and its structure is shown in the table below.

[0088]

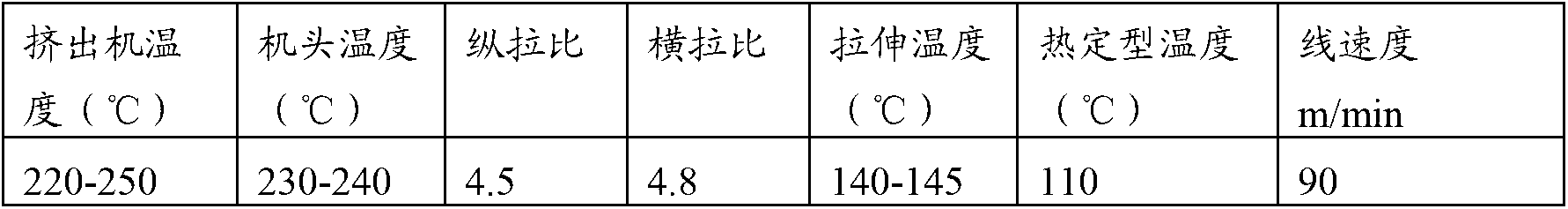

[0089] Processing technology and parameters

[0090]

[0091] The functional layer of the polypropylene biaxially oriented film in Example 2 is measured by differential scanning calorimetry (DSC), and the melting peak area on the DSC curve with a melting point lower than 90 degrees accounts for about 75% of the total area of the DSC curve.

Embodiment 3

[0093] The BOPP thermal lamination protective film is produced on the 5-layer co-extruded double-bubble biaxial stretching equipment, and its structure is shown in the table below.

[0094]

[0095] Processing technology and parameters

[0096]

[0097] The functional layer of the polypropylene biaxially oriented film in Example 3 was measured by differential scanning calorimetry (DSC), and the melting peak area on the DSC curve with a melting point lower than 90 degrees accounted for about 72% of the total area of the DSC curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com