Method for producing Al-Mn-Zn-Sc aluminum alloy foil for automobile radiating fin by continuous roll casting

A scandium aluminum alloy and heat sink technology, which is applied in the field of aluminum alloy foil processing, can solve the problems of difficult control of plate shape, low yield rate, and high cost, and achieve the effects of uniform thickness, high yield rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Typical Example 1: 0.06mm thick aluminum-manganese-zinc-scandium alloy automotive heat sink aluminum foil

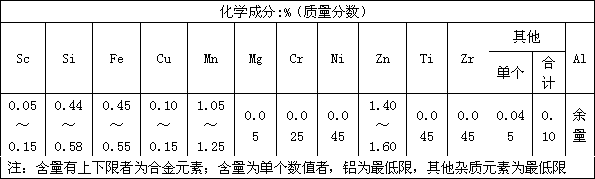

[0067] The specific chemical composition mass fraction of the aluminum alloy foil for automobile radiators is:

[0068] Sc: 0.06, Si: 0.44%, Fe: 0.46%, Cu: 0.11%, Mn: 1.06%, Mg: 0.05%,, Zn: 1.47%, Cr≤0.017, Ni, ≤0.014, Ti, ≤0.012, Zr : ≤0.026, the balance is Al.

[0069] a. The production process of cast-rolled coils is: Furnace preparation→furnace material preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining) → Degassing and slag removal in the degassing box → Filtration and slag removal by double-channel and double-stage ceramic filter plates in the filter box → Cast and rolled into 7.0mm continuous cast-rolled plates, and then rolled into cast-rolled coils (ie: cast-rolled plates and strips), Among them, the regulations on waste in the preparation of ...

Embodiment 2

[0073] Typical Example 2: 0.10mm thickness aluminum-manganese-zinc-scandium alloy automotive heat sink aluminum foil

[0074] The specific chemical composition mass fraction of the aluminum alloy foil for automobile radiators is:

[0075] Sc: 0.09, Si: 0.47%, Fe: 0.51%, Cu: 0.13%, Mn: 1.11%, Mg: 0.05%, Zn: 1.53%, Cr≤0.016, Ni, ≤0.018, Ti, ≤0.014, Zr: ≤0.031, the balance is Al.

[0076] a. The production process of cast-rolled coils is: Furnace preparation→furnace material preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining) → Degassing and slag removal in the degassing box → Filtration and slag removal by double-channel and double-stage ceramic filter plates in the filter box → Cast and rolled into 7.0mm continuous cast-rolled plates, and then rolled into cast-rolled coils (ie: cast-rolled plates and strips), Among them, the regulations on waste in the preparation o...

Embodiment 3

[0080] Typical Example 3: 0.14mm thick aluminum-manganese-zinc-scandium alloy automotive heat sink aluminum foil

[0081] The specific chemical composition mass fraction of the aluminum alloy foil for automobile radiators is:

[0082] Sc: 0.11, Si: 0.50%, Fe: 0.53%, Cu: 0.14%, Mn: 1.15%, Mg: 0.05%, Zn: 1.51%, Cr≤0.013, Ni, ≤0.016, Ti, ≤0.018, Zr: ≤0.28, the balance is Al.

[0083] a. The production process of cast-rolled coils is: Furnace preparation→furnace material preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining) → Degassing and slag removal in the degassing box → Filtration and slag removal by double-channel and double-stage ceramic filter plates in the filter box → Cast and rolled into 7.0mm continuous cast-rolled plates, and then rolled into cast-rolled coils (ie: cast-rolled plates and strips), Among them, the regulations on waste in the preparation of fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com