Etching and baking equipment and operation method thereof

A baking equipment and reaction furnace technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of inability to etch epitaxial substrates, influence of baking temperature, large installation and use space of purification workshop and other issues, to reduce the frequency of equipment maintenance and cleaning, save installation space and use space, and achieve the effect of small equipment size and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

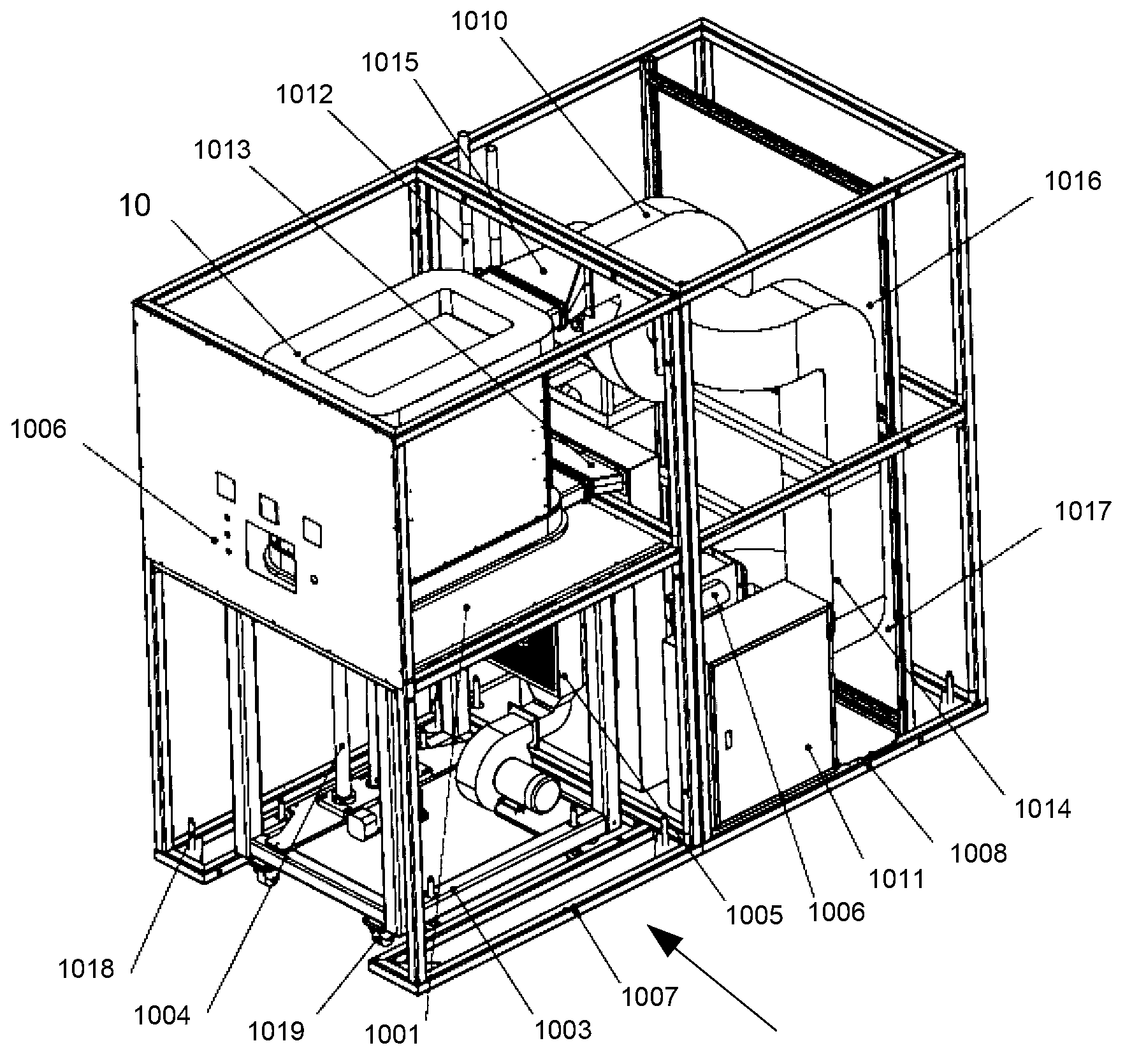

[0032] See figure 1 , which shows a perspective view of the chlorine or chloride etching and baking equipment of the present invention, from which the overall layout of the etching and baking equipment can be clearly seen.

[0033] An operation panel 1006 is arranged on the upper front of the etching and baking equipment, and several control buttons, indicator lights, touch screens and other devices are arranged on the operation panel 1006 . In order to facilitate the user's operation, the installation height of these devices can be set to be roughly level with the height of the user's line of sight. The etching and baking equipment is composed of two external frames 1007 and 1008 arranged in front and back, that is, the first external frame 1007 and the second external frame 1008, wherein the first external frame 1007 mainly accommodates the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com