Preparation method of papermaking filling materials

A technology of fillers and mixtures, applied in the field of compound preparation, can solve the problems of hindering the formation of particles and damage to paper strength, and achieve the effects of good stability, strong color retention and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

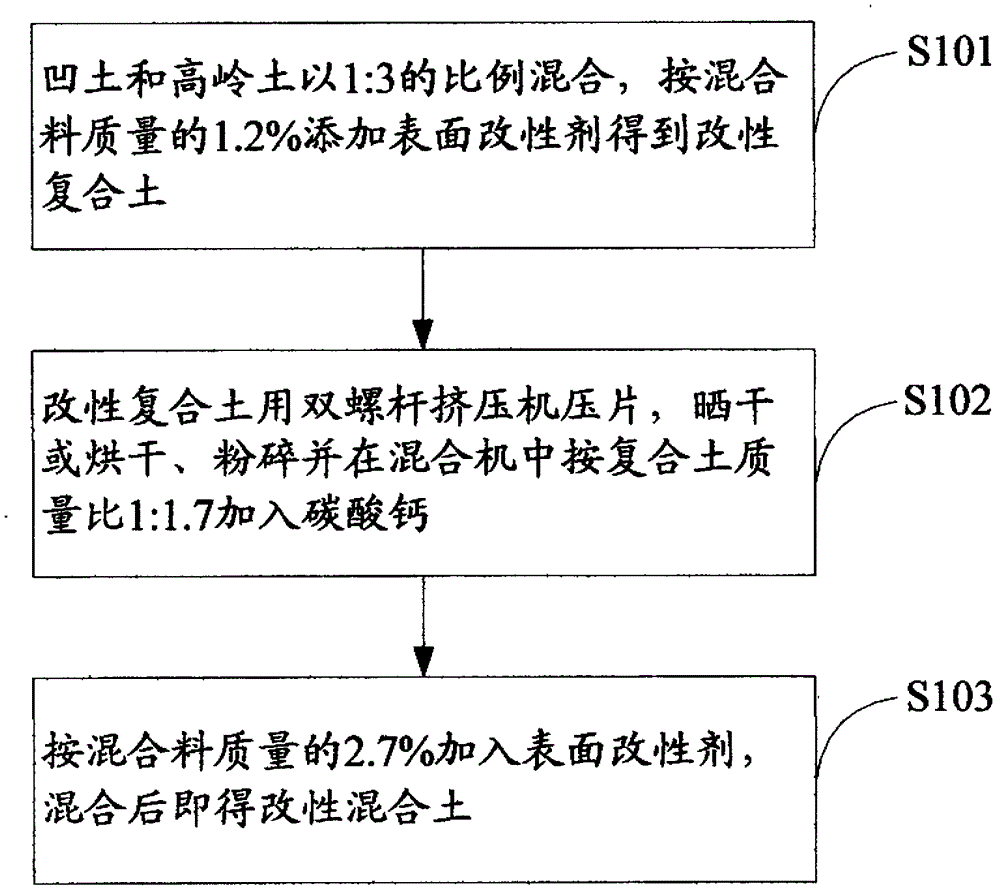

[0014] figure 1 The process flow of the method for preparing papermaking fillers provided by the embodiments of the present invention is shown, and the details are as follows:

[0015] The embodiments of the present invention provide a method for preparing paper-making fillers by using attapulgite, kaolin, calcium carbonate and surface modifiers as main fillers.

[0016] In the embodiment of the present invention, the main components of the filler are attapulgite, kaolin, calcium carbonate and surface modifier.

[0017] In step S101, attapulgite and kaolin are mixed in a ratio of 1:3, and a surface modifier is added according to 1.2% of the mass of the mixture to obtain a modified composite soil;

[0018] In step S102, the modified composite soil is pressed into tablets with a twin-screw extruder, dried or dried, pulverized, and calcium carbonate is added to the mixer at a mass ratio of 1:1.7 to the composite soil;

[0019] In the embodiment of the present invention, the mod...

Embodiment 1

[0024] 1. Attapulgite 10Kg, kaolin 30Kg, add titanate coupling agent 0.48Kg, stir at room temperature for 15 minutes to obtain modified composite soil;

[0025] 2. The modified composite soil is pressed into tablets with a twin-screw extruder, dried in the sun or dried until the water mass percentage is less than 4%, and crushed to 4.3 μm;

[0026] 3. Add 68.8Kg of calcium carbonate with a thickness of 4.3 μm and a whiteness > 82 to the mixer, mix it with the modified composite soil, and stir for 20 minutes;

[0027] 4. Add 2.9Kg of titanate coupling agent to the mixture, and mix at 70°C for 40 minutes to obtain about 112Kg of modified mixed soil.

Embodiment 2

[0029] 1. Attapulgite 15Kg, kaolin 45Kg, add aluminate coupling agent 0.72Kg, stir at room temperature for 15 minutes to obtain modified composite soil;

[0030] 2. The modified composite soil is pressed into tablets with a twin-screw extruder, dried in the sun or dried until the water mass percentage is less than 4%, and crushed to 4.3 μm;

[0031] 3. Add 103.2Kg of calcium carbonate with a thickness of 4.3 μm and a whiteness > 82 to the mixer, mix it with the modified composite soil, and stir for 20 minutes;

[0032] 4. Add 4.4Kg of aluminate coupling agent to the mixture, and mix at 70°C for 40 minutes to obtain about 168Kg of modified mixed soil.

[0033] Embodiments of the present invention can largely solve the problems associated with the use of finely divided fillers by adding coagulants to the formulation; making fillers of various size distributions by impeding the formation of particles or removing them from the product would create Provides optically more effectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com