High-speed high-strength brake pad

A high-strength, brake pad technology, applied in the direction of friction linings, mechanical equipment, brake parts, etc., can solve the problems of steel back deformation, large safety hazards, virtual welding, etc., to increase strength, eliminate welding deformation, and avoid easy The effect of dropping edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

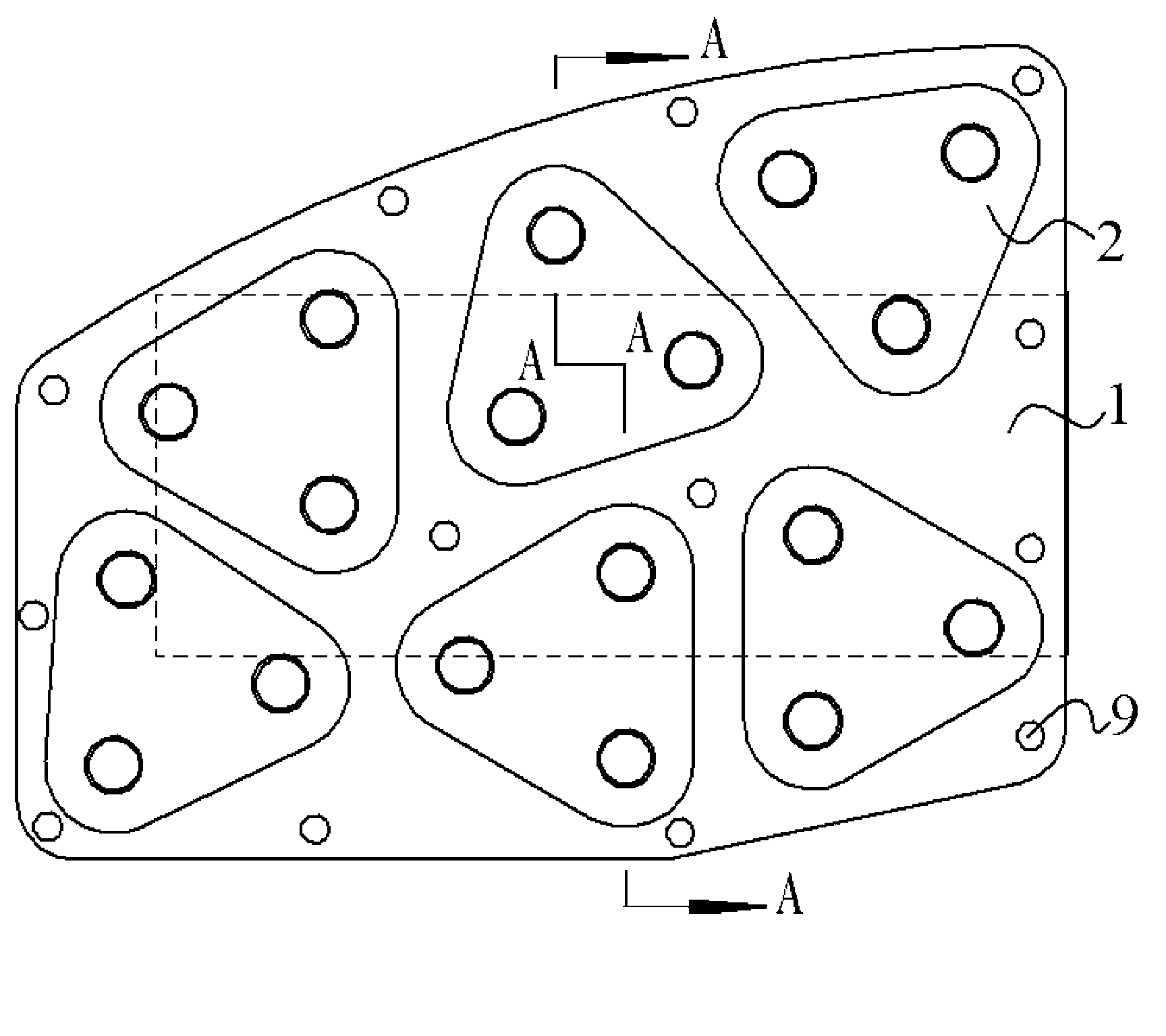

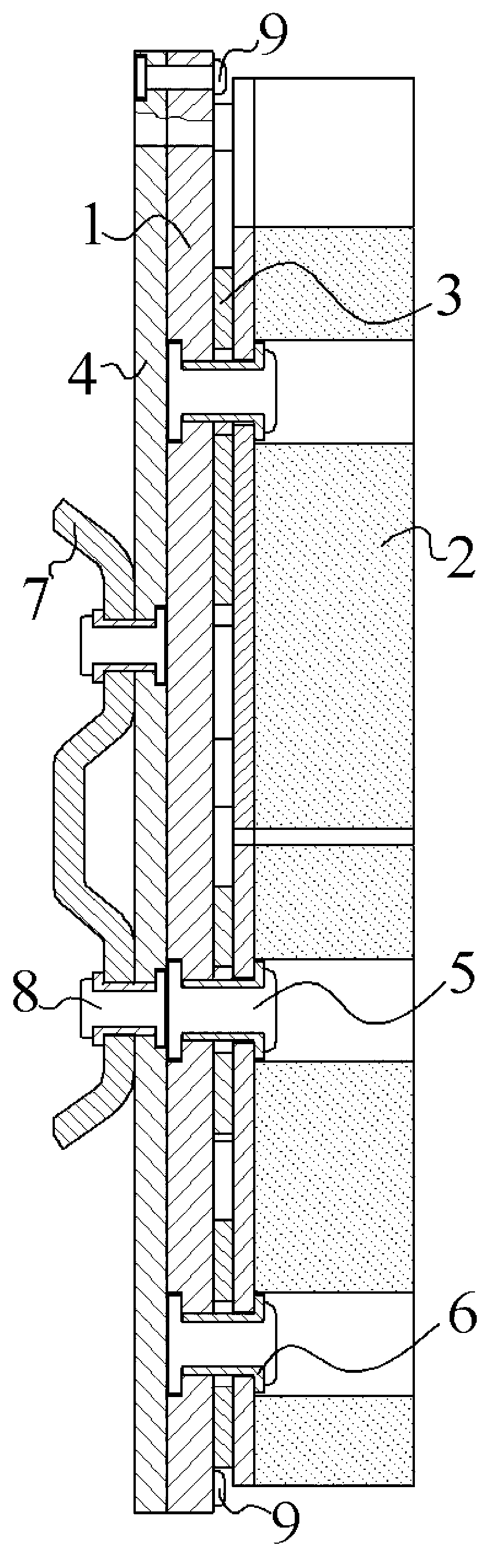

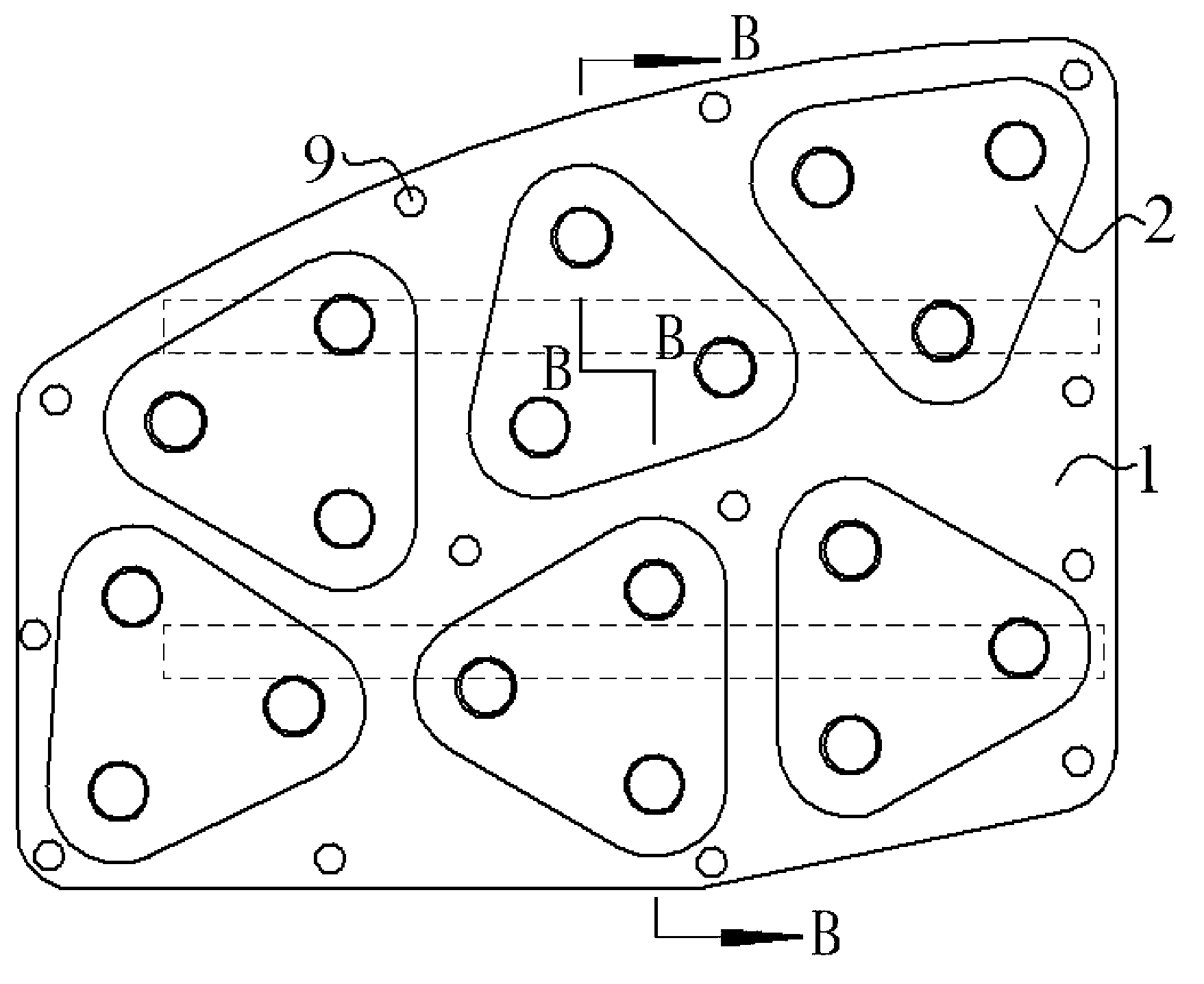

[0016] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1~Figure 4 As shown, the high-speed high-strength brake pad mainly includes a steel back 1, a brake block 2 and a dovetail plate 7, the front of the steel back 1 is riveted with a brake block 2, the back of the steel back 1 is riveted with a connecting plate 4, and the connecting plate 4 is provided with Dovetail plate 7; the weight percentage of the material formula used in the brake block 2 is: copper powder 11, iron powder 51, tin powder 1, graphite 5, ferroboron 2, molybdenum disulfide 4, ferromanganese 3, aluminum oxide 5. Silicon carbide 13, silicon dioxide 5, the above-mentioned material formula is cold-pressed and sintered on the skeleton to make the brake block 2 according to the existing technology. figure 1 The dotted line in is the outline of the outer edge of the dovetail plate 7, and the number of brake blocks 2 depends on the area of the steel bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com