Barn solar direct heating device and solar auxiliary direct heating barn

A technology for heating devices and solar thermal collectors, which is applied in solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve problems such as high cost, increased power consumption, and loss, so as to reduce the cost of popularization and application, and reduce pollutants Emission, the effect of increasing the baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

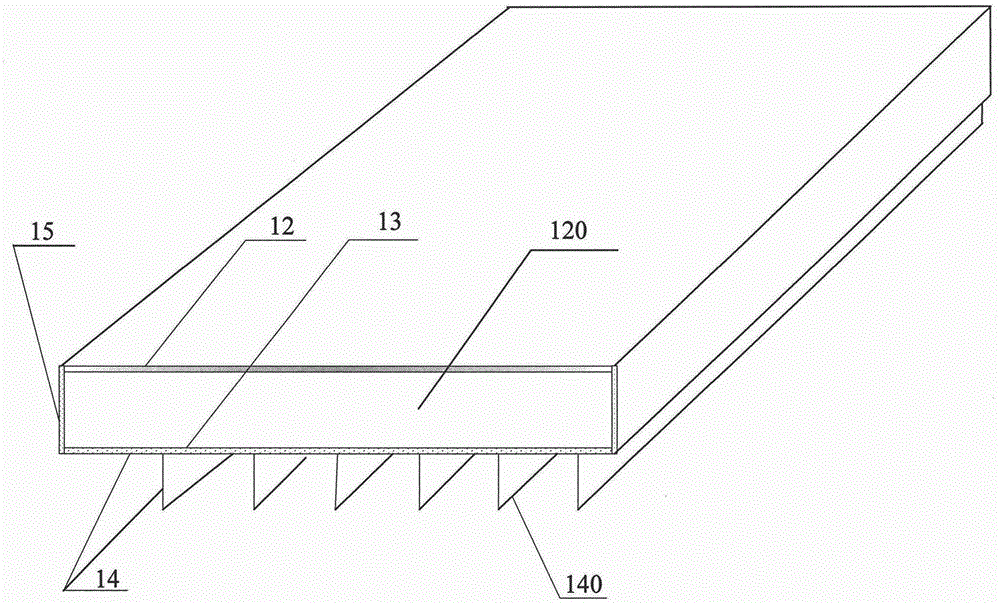

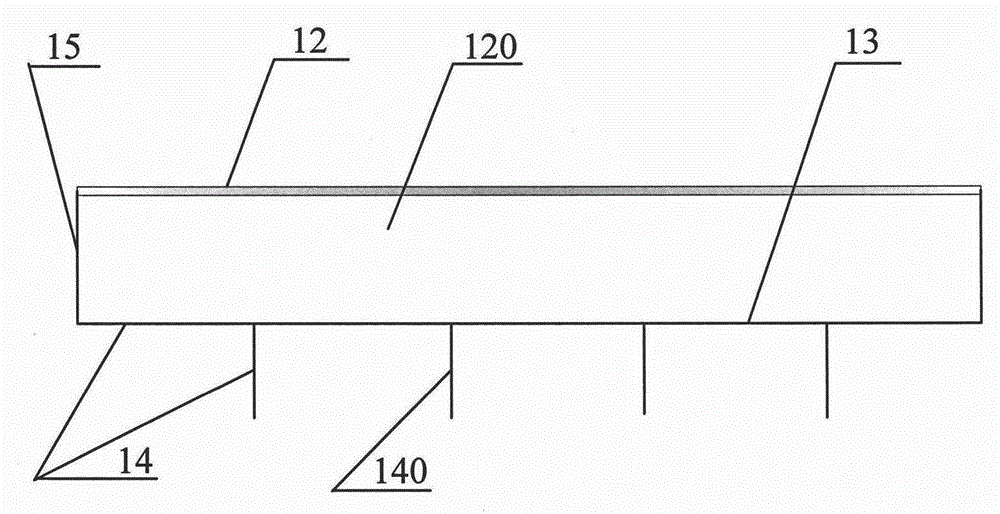

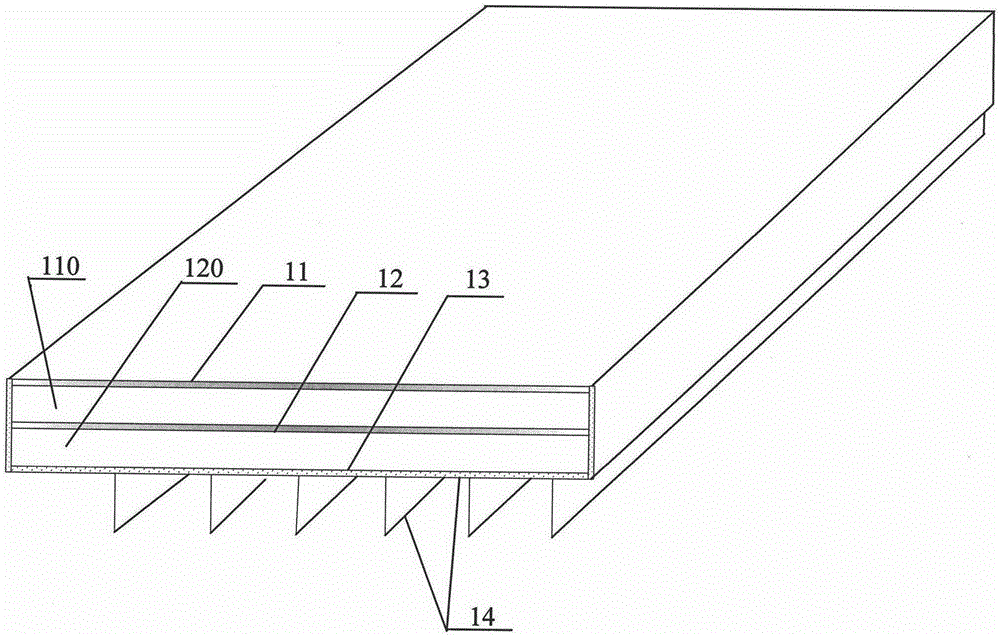

[0035] The first embodiment of the solar direct heating device for the barn of the present invention is as follows: figure 1 , figure 2 and Figure 5 shown.

[0036] The solar direct heating device for the barn of the present invention comprises a light-transmitting plate 11, a hollow light-transmitting insulation layer 110, a solar heat collecting plate 13, a heat dissipation component 14 and a frame 15, etc., the light-transmitting plate 11 is positioned at the sunny side, the light-transmitting plate 11, The solar thermal collector plate 13 and the frame 15 are airtightly enclosed to form a hollow light-transmitting thermal insulation layer 110; the solar thermal collector plate 13 includes a metal substrate 130 and a heat-absorbing coating 131, and the sun-facing surface of the metal substrate 130 is covered with a heat-absorbing coating 131. The other side of the heat-absorbing coating 131 of the metal substrate 130 directly faces the baking chamber 21 and is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com