Potentiometric titration determination method of cemented sand gravel cement content

A technology of cemented sand and gravel, which is applied in the direction of chemical analysis by titration, can solve the problems of cumbersome test steps, many influencing factors, and inconvenient on-site tests, and achieve the effect of reducing safety hazards and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, the mensuration of gelled sand gravel cement content

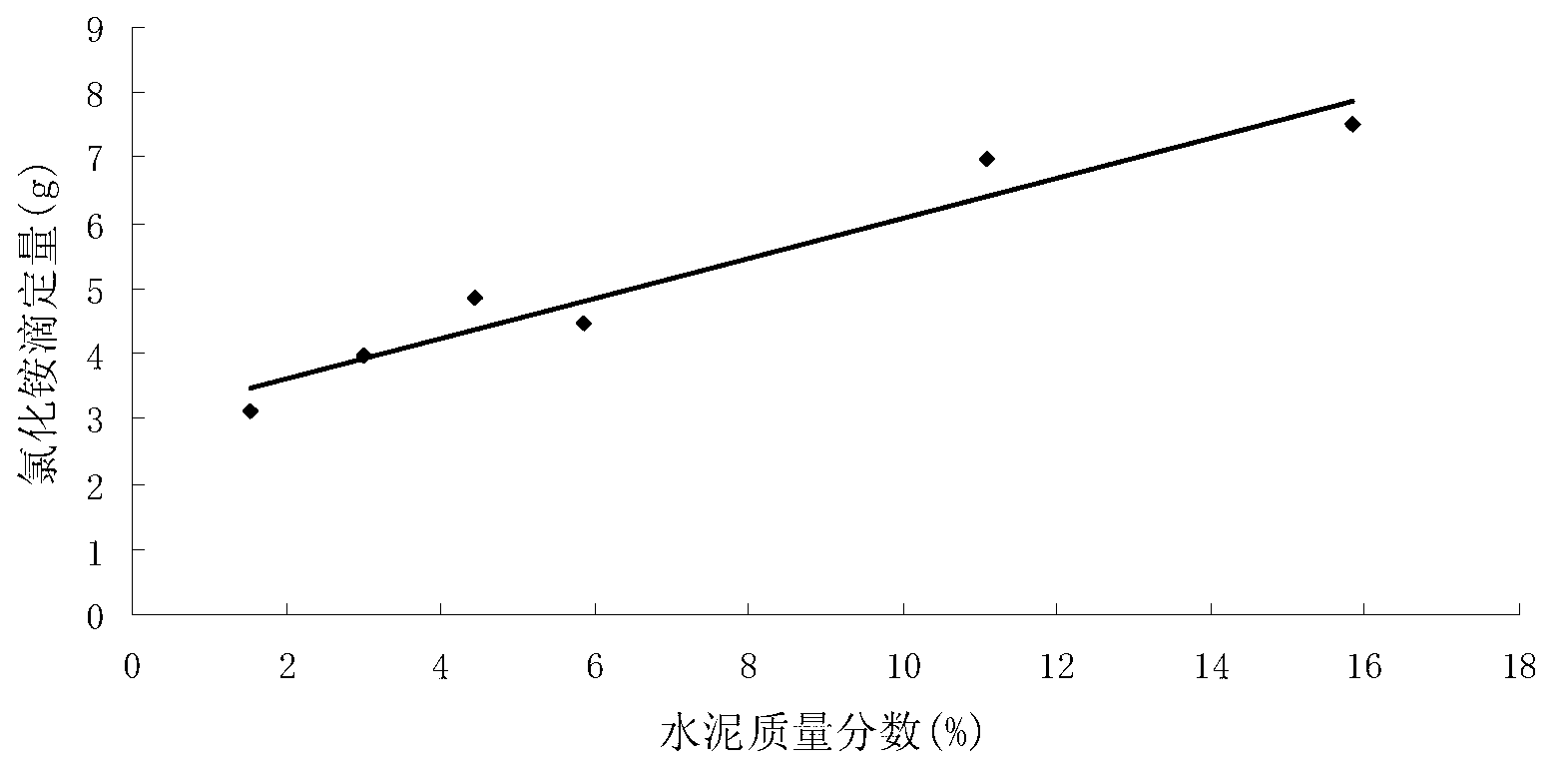

[0019] (1) Drawing of determination standard curve

[0020] Prepare 500g of standard cementitious sand and gravel / cement mixtures with different cement contents (mass percentages are 1.52%, 3%, 4.44%, 5.85%, 11.10% and 15.84%); Add 2L of water to the gravel / cement mixture to dilute to obtain a standard mortar mixture, and stir thoroughly; add phenolphthalein indicator (0.5% concentration) to the 30g clear solution of each standard mortar solution obtained above, and then use NH 4 Cl aqueous solution (10% by mass) was titrated to colorless, and the NH 4 Cl aqueous solution was titrated to a colorless titration, and NH 4 The titration of Cl aqueous solution is plotted to obtain standard curve to the cement content in different standard setting sand gravel / cement mixtures, and the obtained standard curve is as follows figure 1 shown.

[0021] The linear correlation coefficient of the drawn standard c...

Embodiment 2

[0025] Embodiment 2, the mensuration of gelled sand gravel cement content

[0026] (1) Drawing of determination standard curve

[0027] Prepare 500g of standard gelled sand and gravel / cement mixtures with different cement contents (mass percentages are 1.48%, 2.94%, 4.34%, 5.72%, 10.88% and 15.54%); Add 2L of water to the gravel / cement mixture for dilution to obtain a standard mortar mixture, and stir thoroughly; add a phenolphthalein indicator (0.5% concentration) to the 30 g clear liquid of each standard mortar mixture obtained above, and then use NH 4 Cl aqueous solution (10% by mass) was titrated to colorless, and the NH 4 Cl aqueous solution was titrated to a colorless titration, and NH 4 The titration of Cl aqueous solution is plotted to obtain standard curve to the cement content in different standard setting sand gravel / cement mixtures, and the obtained standard curve is the same as figure 1 similar.

[0028] The linear correlation coefficient of the drawn standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com