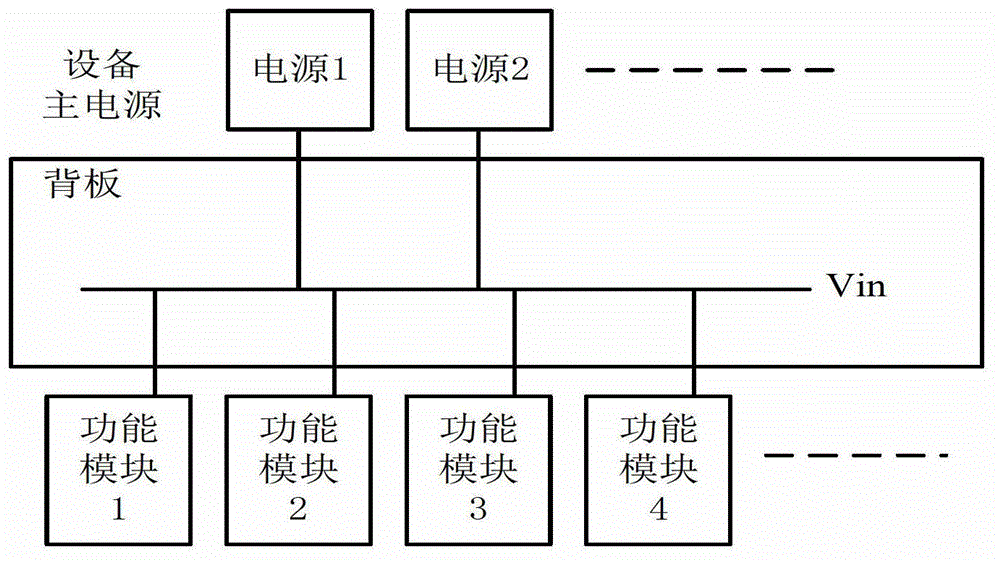

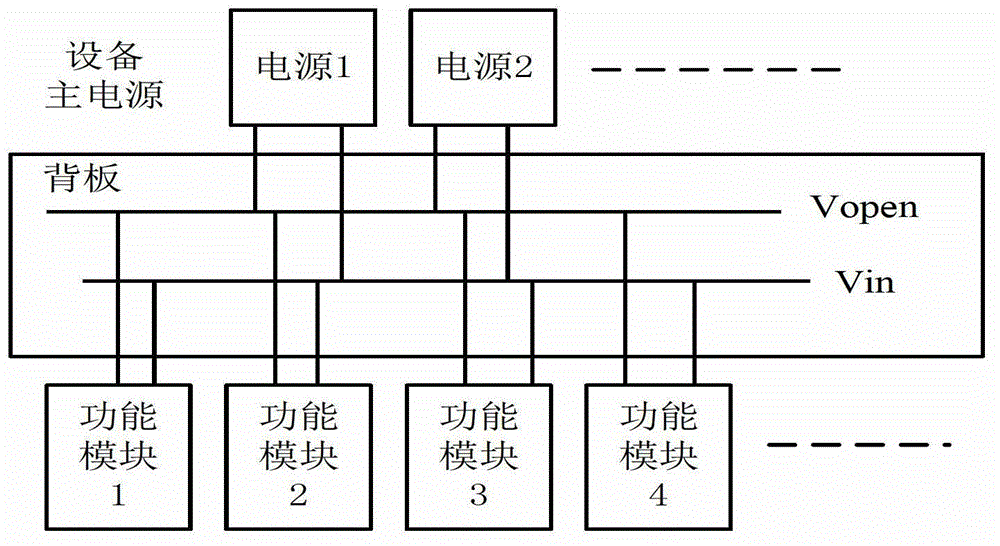

Concentrated power supply rack-mounted equipment function module hot plug control system

A technology for device functions and control systems, applied in the field of communications, can solve the problem of high cost of hot-swap control circuits, and achieve the effects of significant cost-effectiveness, simple circuit implementation, and reduced system costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

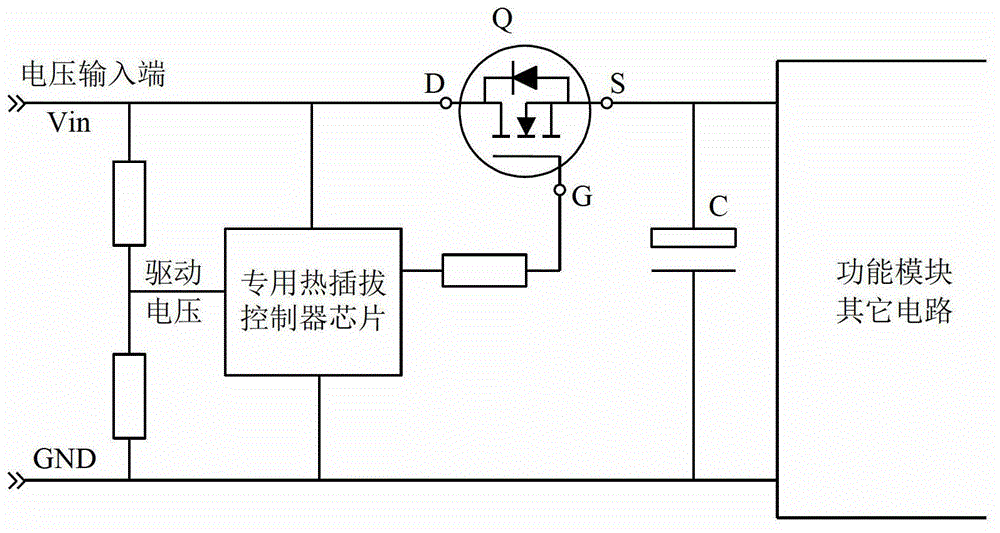

[0033] In this example, the function module hot swap control circuit structure is as follows Figure 4 As shown, the switching device adopts an N-channel CMOS field effect transistor Q, and the control circuit is composed of a first resistor R1, a second resistor R2, and a capacitor C1. One end of the first resistor R1 is connected to the driving voltage, the other end is connected to the second resistor R2, the other end of the second resistor R2 is grounded, the capacitor C1 is connected in parallel with the second resistor R2, and the connection point of the first resistor R1 and the second resistor R2 (ie, the capacitor C1 The non-grounded terminal of the switch device is connected to the gate of the field effect transistor Q as the control terminal of the switching device, and the drain and source of the field effect transistor Q are connected in series with the voltage input terminal. In this example, the resistors R1 and R2 can be ordinary metal film resistors, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com