Preparation method and laminated structure of tensile strain Ge film

A stacked structure and thin-film technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of limiting the further application of strained Ge thin films, increasing the cost of buffer layers, and the small tensile stress of Ge thin films, so as to reduce the thickness , reduce cost, and reduce the effect of threading dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

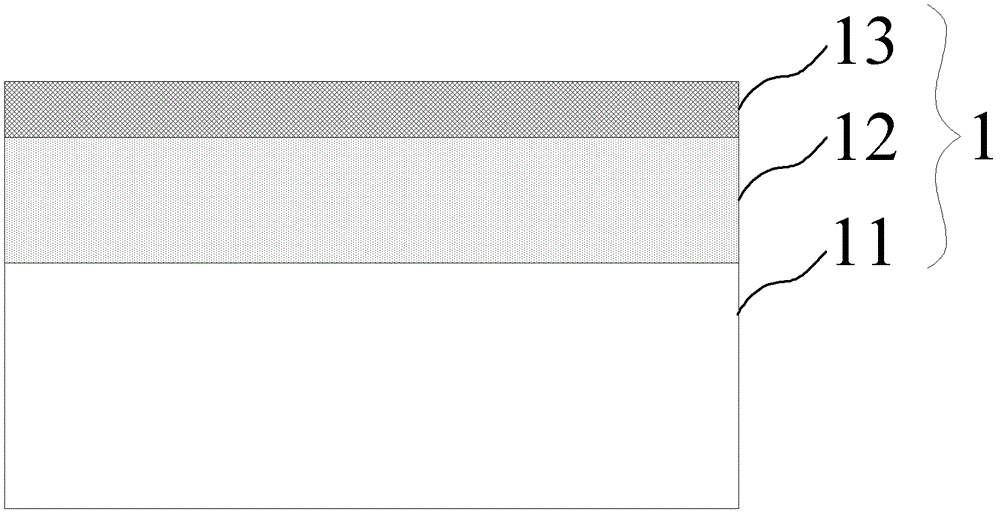

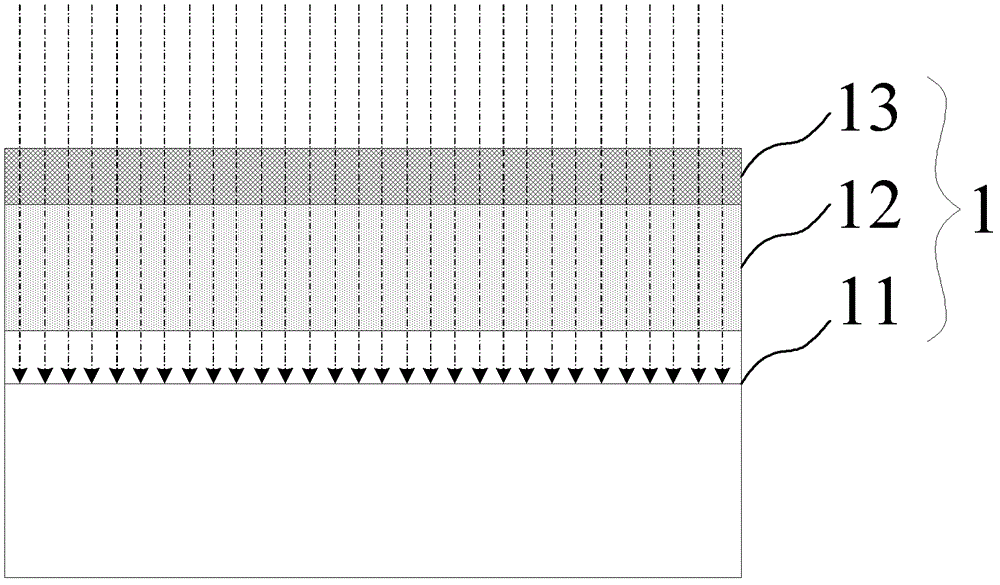

[0022] As shown in the figure, the present invention provides a method for preparing a tensile strained Ge thin film, at least comprising the following steps:

[0023] see figure 1 , providing a GaAs substrate 11 on which In x Ga 1-x As layer 12 and top Ge thin film 13, the In x Ga 1-x The In composition x in the As layer 12 is 0x Ga 1-x The thickness of the As layer 12 does not exceed the critical thickness of its growth on the GaAs substrate 11, so that the thickness of the top Ge film 13 does not exceed its growth on the In x Ga 1-x The critical thickness on the As layer 12 is used to prepare samples of Ge thin films. In this embodiment, In is epitaxially grown on the GaAs substrate 11 by molecular beam epitaxy (MBE) or metal organic compound chemical vapor deposition (MOCVD). x Ga 1-x As layer 12 and top Ge film 13; the In x Ga 1-x The thickness of the As layer is less than 1nm-1um. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com