a photolithography method

A technology of photolithography and photolithography pattern, which is applied in the field of photolithography, can solve the problem of photoresist drop and achieve the effect of improving the line width rough phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

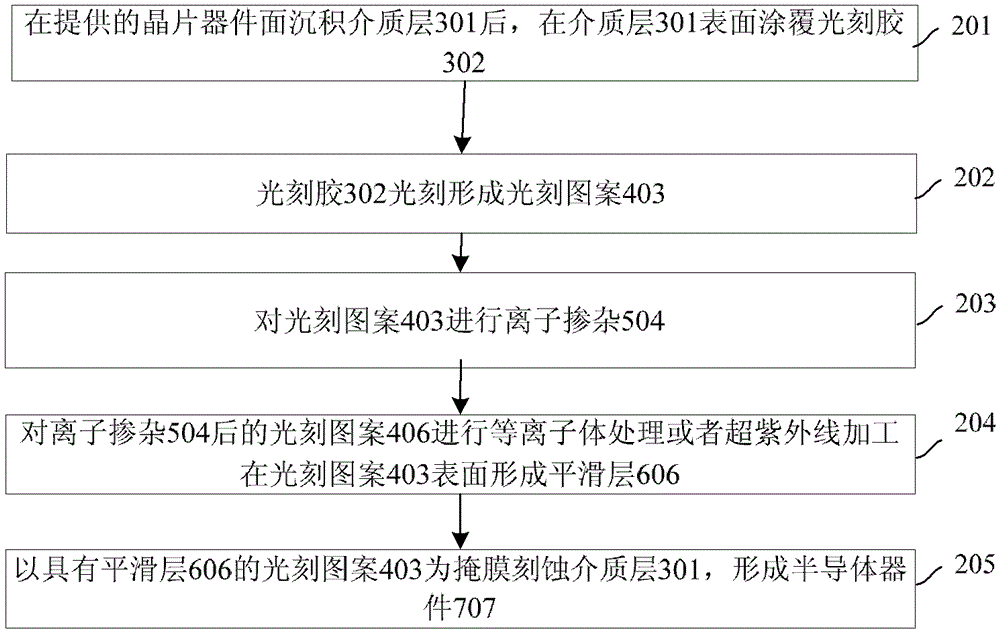

[0024] The photolithography method proposed by the present invention can effectively improve the line width roughness (LWR) phenomenon of the photolithographic pattern without reducing the resolution and sensitivity of the photoresist, thereby better controlling the etching of the dielectric layer to form a semiconductor Device CD.

[0025] Combine below Figure 3-7 The simplified cross-sectional schematic diagram of the structure of the photolithography and etching method proposed by the present invention is shown in detail as figure 2 The flow chart of the photolithography and etching method steps proposed by the present invention is shown.

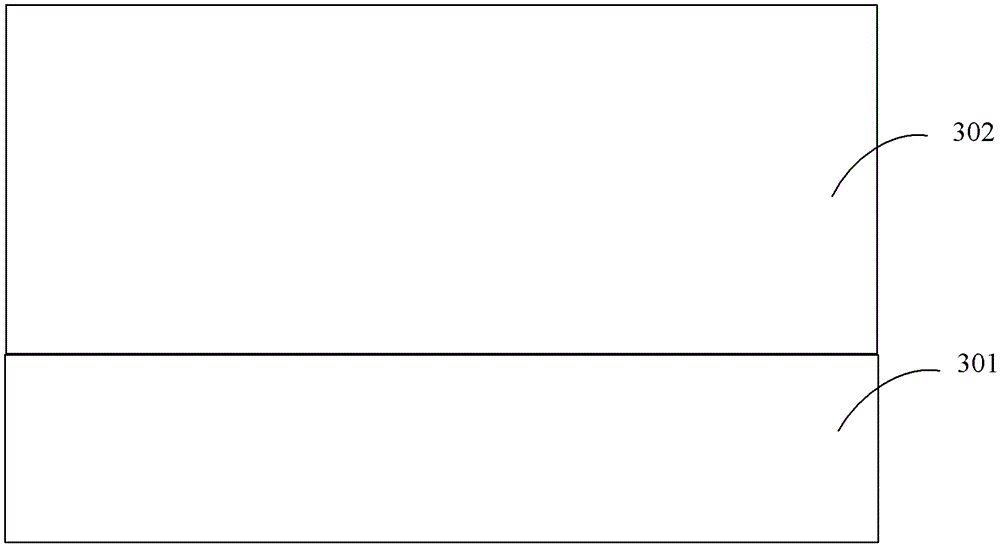

[0026] Step 201, image 3 A schematic diagram of the cross-sectional structure of step 201 of the etching method proposed by the present invention, such as image 3 As shown, after the dielectric layer 301 is deposited on the device surface of the provided wafer, a photoresist 302 is coated on the surface of the dielectric layer 301...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com