Method and apparatus for deposition

A composite, near-infrared technology for sustainable manufacturing/processing, final product manufacturing, conductive patterning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

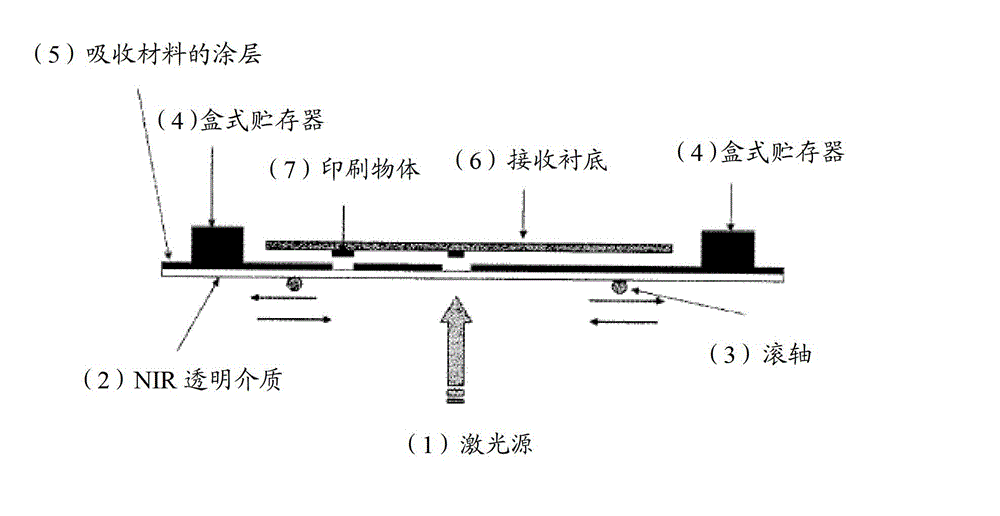

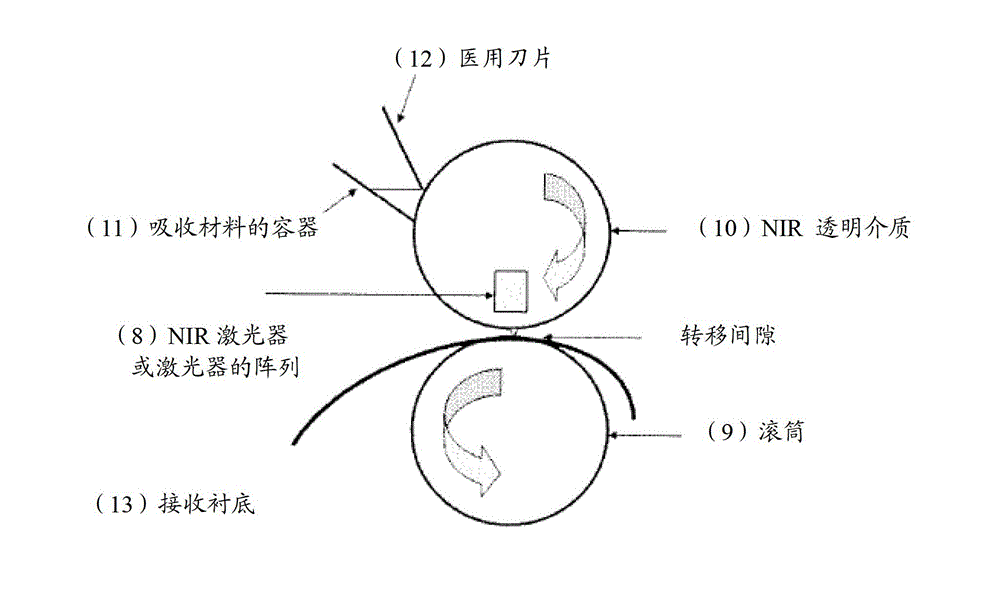

[0079] In the present invention, the laser source consists of a pulsed near-infrared (NIR-range 800 to 2000 nm) laser or an array of lasers. Power density can be optimized based on beam optics, gap distance, and desired resolution of the printed object. The power density can also be chosen such that the electromagnetic energy is absorbed by the water diluent, but not sufficient to vaporize, decompose or burn the other ingredients of the composition. Power density can be greater than 10 4 W / cm 2 . Energy per pulse preferably up to 5J / cm 2 , for example at 10 microjoule / cm 2 to 5J / cm 2 In the range. Recently developed laser diodes enable shorter pulses in the microsecond and femtosecond range, and this makes transfer systems faster and more efficient. The exact choice of beam delivery system can be optimized based on the desired working distance, focal spot size and absorption properties of the material to be transferred.

[0080] The device preferably comprises a NIR tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com