Building board and manufacturing method thereof

A technology of building boards and manufacturing methods, applied in the field of building materials, can solve problems such as poor wall insulation, waste of raw materials, and increased labor force construction intensity, and achieve the effect of changing cracks and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

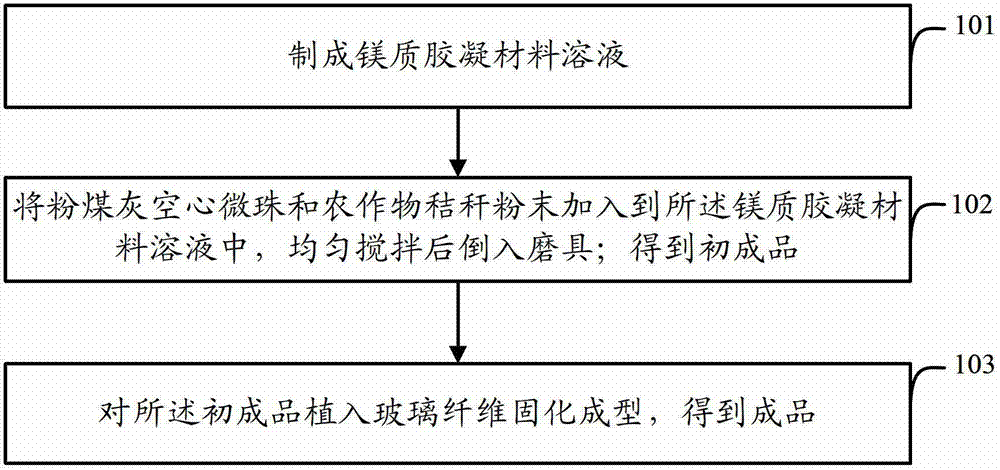

[0054] Step 101: making a magnesium cementitious material solution;

[0055] In step 101, the production of the magnesia cementitious material solution is the initial step in the production of the entire building board. In specific production, the magnesia cementitious material solution is prepared by adding a magnesium-containing compound and dissolving it.

[0056] Step 102: adding fly ash hollow microspheres and crop straw powder into the magnesia gelling material solution, stirring evenly and pouring into a mold; obtaining a primary product;

[0057] In step 102, after adding the predetermined fly ash hollow microspheres and crop straw powder into the prepared magnesia cementitious material solution, the primary product can be obtained after stirring and mixing;

[0058] In addition, in the specific operation, the process of stirring and mixing is completed in the mixer. After mixing, the mixed solution is poured into the abrasive mold for producing building boards, and th...

Embodiment 3

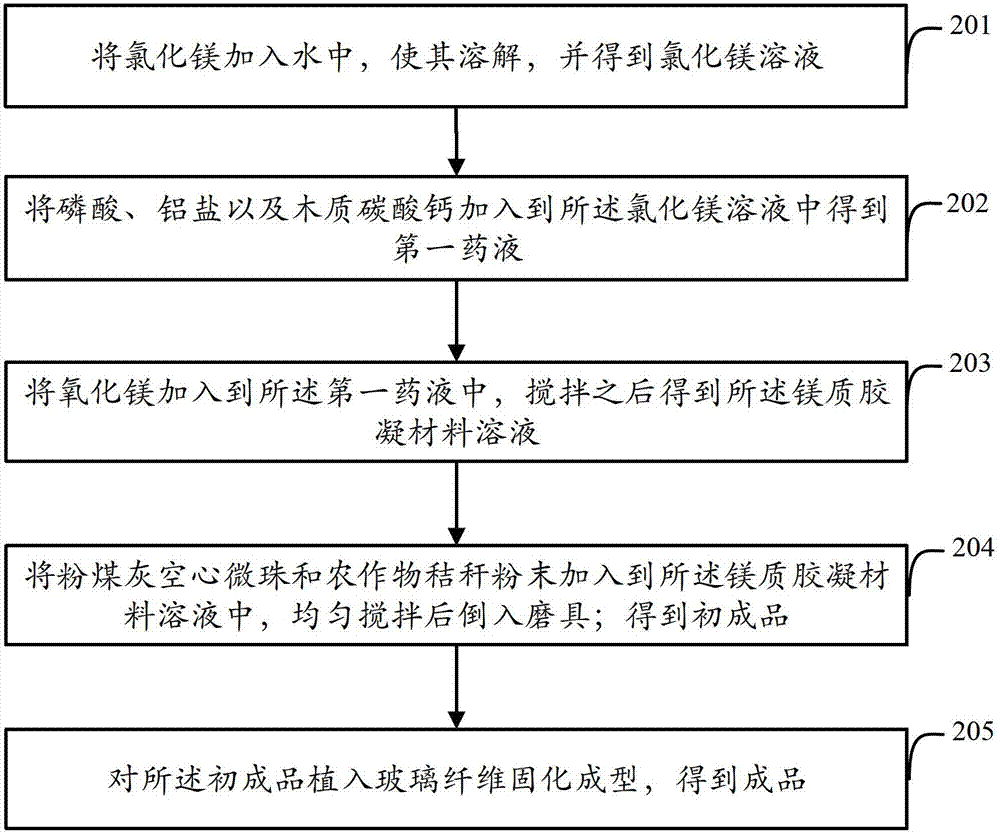

[0063] Step 201: adding magnesium chloride to water to dissolve it to obtain a magnesium chloride solution;

[0064] Step 202: adding phosphoric acid, aluminum salt and lignocalcium carbonate to the magnesium chloride solution to obtain the first medicinal solution;

[0065] Step 203: adding magnesium oxide into the first medicinal solution, and stirring to obtain the magnesium gelling material solution;

[0066] Steps 201-203 are specific preparation methods of the magnesium gelling material solution in the present invention. First, magnesium chloride is added to water to obtain a magnesium chloride solution, and then some modifiers are added, which have the effect of improving the solution. Finally, in the first Magnesium oxide is added to the liquid medicine, and after stirring, a magnesium cementitious material solution will be obtained; in the production process, industrial water is generally used, and at the same time, magnesium chloride and magnesium oxide can be some w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com