Water-based conducting polymer/metal composite nano-coating for porous wall board and preparation method thereof

A conductive polymer, metal nanotechnology, applied in conductive coatings, coatings, etc., can solve the problems of limiting the popularization and application of shielding coatings, poor electromagnetic shielding effect, and difficult to meet the requirements of electrical conductivity, and achieves less oxidation and improved stability. , the effect of reducing the areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

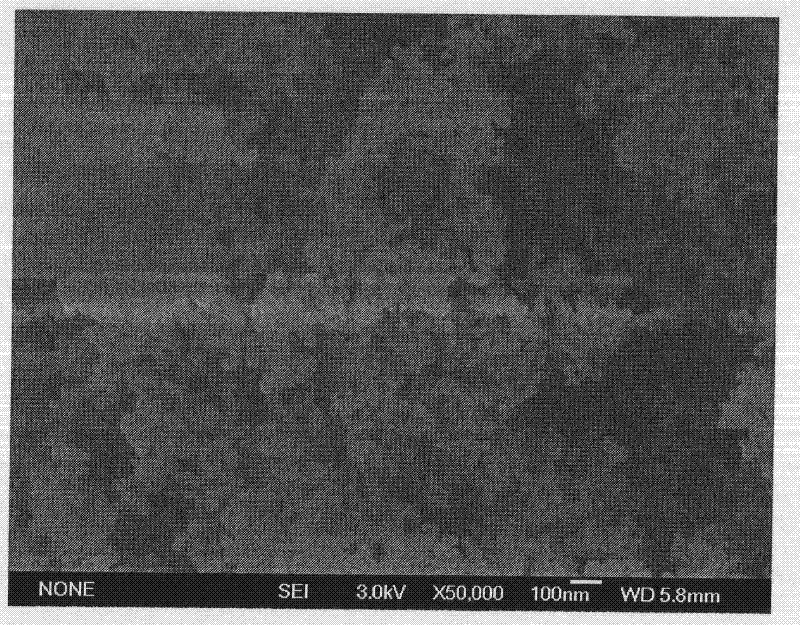

[0033] Example 1 Preparation of water-based conductive polymer / metal composite nano-coating for porous wallboard

[0034] 1) adding 0.3% sodium dodecylbenzenesulfonate surfactant into water, then adding nano-nickel particles for ultrasonic mixing for 2 hours, filtering, separating, washing, and drying to obtain modified nano-nickel particles; The amount of nano-nickel particles added is 100g / L water;

[0035] 2) Add the modified nano-nickel particles obtained in step 1) into water, and ultrasonically disperse them until uniform. The amount of the modified nano-nickel particles is 10 millimoles per liter of water.

[0036] 3) add macromolecular monomer aniline and organic acid dodecylbenzenesulfonic acid, ultrasonically mix uniformly, form mixed emulsion, the add-on of monomer is 100 millimoles of every liter of mixed solution; The add-on of organic acid and monomer The molar ratio is 1:1;

[0037] 4) dissolving the oxidant ammonium persulfate in water to form a solution, the...

Embodiment 2

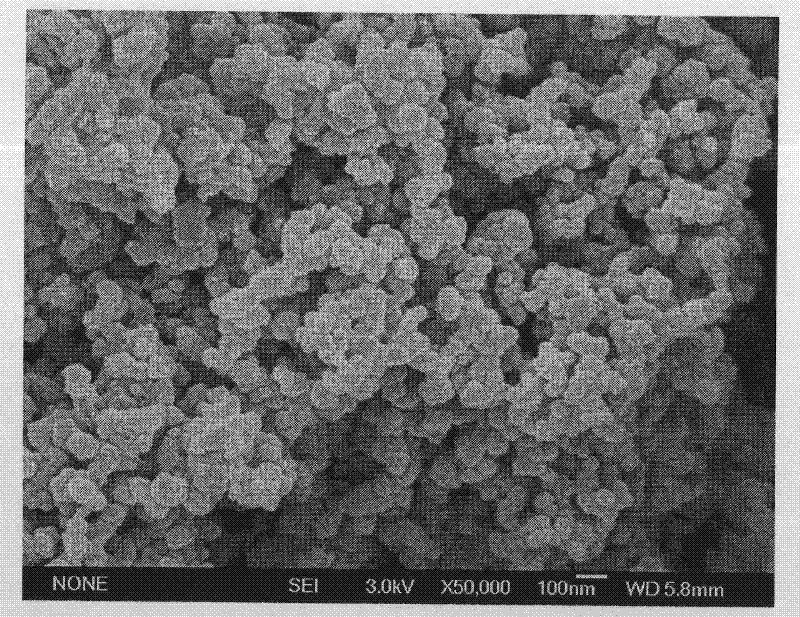

[0043] Example 2 Preparation of water-based conductive polymer / metal composite nano-coating for porous wallboard

[0044] 1) adding 0.5% sodium dodecylsulfonate surfactant into water, then adding metal silver nanoparticles and ultrasonically mixing for 2 hours, filtering, separating, washing, and drying to obtain modified metal nanoparticles; The amount of metal nanoparticles added is 100g / L water;

[0045] 2) Add the modified metal nanoparticles obtained in step 1) into water, and ultrasonically disperse them until they are uniform. The amount of modified metal nanoparticles added is 100 millimoles per liter of water.

[0046] 3) adding polymer monomer pyrrole and oleic acid, ultrasonically mixing to form a mixed emulsion, the amount of monomer added is 500 millimoles per liter of mixed solution; the molar ratio of the amount of organic acid added to the monomer is 1:1;

[0047] 4) dissolving the oxidizing agent ferric chloride into water to form a solution, the amount of th...

Embodiment 3

[0053] Example 3 Preparation of water-based conductive polymer / metal composite nano-coating for porous wallboard

[0054] 1) adding 0.2% surfactant sodium lauryl sulfate into water, adding metal nano-copper particles and ultrasonically mixing for 2 hours, filtering, separating, washing, and drying to obtain modified metal nano-copper particles; The amount of metal nanoparticles added is 100g / L water;

[0055] 2) Add the modified metal nanoparticles obtained in step 1) into water, and ultrasonically disperse until uniform, and the amount of the modified metal nanoparticles added is 50 millimoles per liter of water;

[0056] 3) Add polymer monomer thiophene and organic acid azobenzenesulfonic acid, and ultrasonically mix uniformly to form a mixed emulsion. The amount of monomer added is 500 millimoles per liter of mixed solution, and the molar ratio of the amount of organic acid added to the monomer 1:1;

[0057] 4) dissolving oxidizing agent potassium perbromate and forming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com