Method for converting echinocandin B by using microbial enzyme

An echinocandin, conversion technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of easy separation and purification, improved yield and purity, and high molar conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1), fermentation of echinocandin B deacylase

[0040] Strains: Actinoplanes utahensis NRRL12052, purchased from the American Agricultural Research Culture Collection.

[0041] Medium formula:

[0042] Slant medium: yeast powder 0.3%, malt extract powder 0.3%, peptone 0.5%, glucose 1.0%, agar 2.5%, pH 7.0-7.2, cultured at 30°C for 5-7 days

[0043] Seed medium: sucrose 2.5%, oat flour 2%, yeast powder 0.25%, K 2 HPO 4 0.1%, KCl 0.05%, MgSO 4 ·7H 2 O 0.05%, FeSO 4 ·7H 2 O 0.0002%, pH=6.8, cultured at 30°C for 4-5 days

[0044] Fermentation medium: 2.5% sucrose, 1.2% peanut meal powder, K 2 HPO 4 0.1%, MgSO 4 ·7H 2 O0.3%, pH=6.8, cultivated at 30°C for 3-4 days

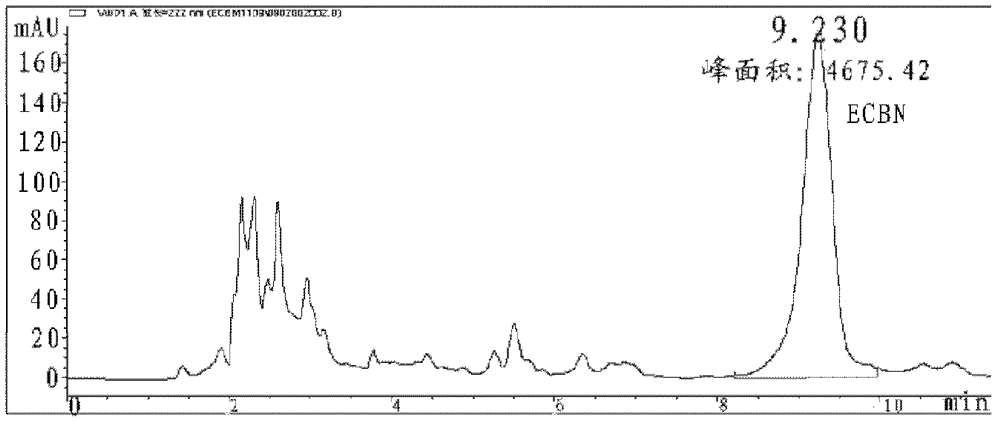

[0045] 2), after the fermentation is completed, add Na to the fermentation broth 2 HPO 4 12H 2 O and NaH 2 PO 4 2H 2 The O concentrations were 6.10 g / L and 5.8 g / L, respectively, and the pH was adjusted to 6.0 with HCl, sonicated for 1 hour, and the supernatant was collected by centrifugation, wh...

Embodiment 2

[0052] 1), fermentation of echinocandin B deacylase

[0053] Strains: Actinoplanes utahensis NRRL12052, purchased from the American Agricultural Research Culture Collection.

[0054] Medium formula:

[0055] Slant medium: yeast powder 0.3%, malt extract powder 0.3%, peptone 0.5%, glucose 1.0%, agar 2.5%, pH 7.0-7.2, cultured at 30°C for 5-7 days

[0056] Seed medium: sucrose 2.5%, oat flour 2%, yeast powder 0.25%, K 2 HPO 4 0.1%, KCl 0.05%, MgSO 4 ·7H 2 O 0.05%, FeSO 4 ·7H 2 O 0.0002%, pH=6.8, cultured at 30°C for 4-5 days

[0057] Fermentation medium: 2.5% sucrose, 1.2% peanut meal powder, K 2 HPO 4 0.1%, MgSO 4 ·7H 2 O0.3%, pH=6.8, cultivated at 30°C for 3-4 days

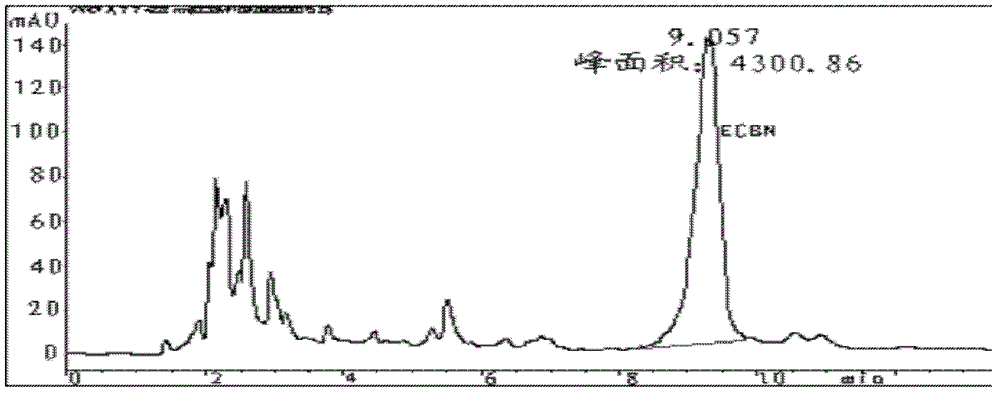

[0058] 2), after the fermentation is completed, add Na to the fermentation broth 2 HPO 4 12H 2 O and NaH 2 PO 4 2H 2 The O concentrations were 18.20 g / L and 15.15 g / L respectively, the pH was adjusted to 7.0 with NaOH, ultrasonicated for 2 hours, and the supernatant was obtained by centrifugation...

Embodiment 3

[0065] 1), fermentation of echinocandin B deacylase

[0066] Strains: Actinoplanes utahensis NRRL12052, purchased from the American Agricultural Research Culture Collection.

[0067] Medium formula:

[0068] Slant medium: yeast powder 0.3%, malt extract powder 0.3%, peptone 0.5%, glucose 1.0%, agar 2.5%, pH 7.0-7.2, cultured at 30°C for 5-7 days

[0069] Seed medium: sucrose 2.5%, oat flour 2%, yeast powder 0.25%, K 2 HPO 4 0.1%, KCl 0.05%, MgSO 4 ·7H 2 O 0.05%, FeSO 4 ·7H 2 O 0.0002%, pH=6.8, cultured at 30°C for 4-5 days

[0070] Fermentation medium: 2.5% sucrose, 1.2% peanut meal powder, K 2 HPO 4 0.1%, MgSO 4 ·7H 2 O0.3%, pH=6.8, cultivated at 30°C for 3-4 days

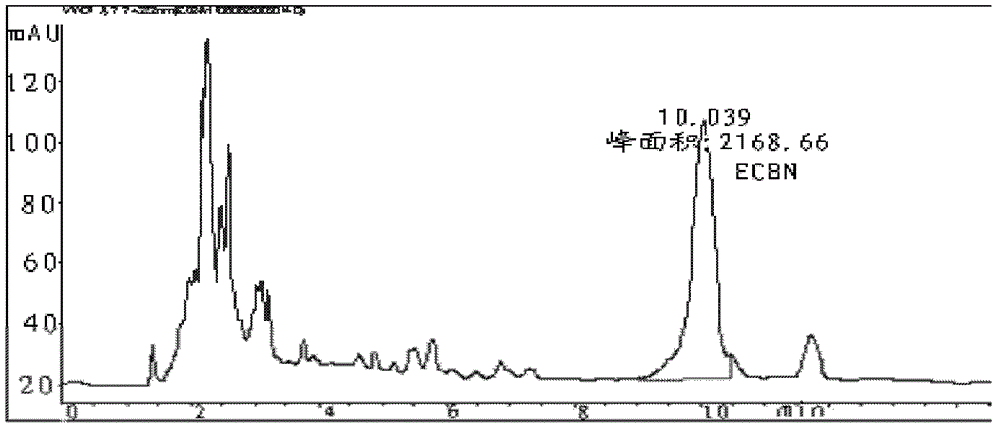

[0071] 2), after the fermentation is completed, add Na to the fermentation broth 2 HPO 4 12H 2 O and NaH 2 PO 4 2H 2 The O concentrations were 12.20 g / L and 10.15 g / L respectively, the pH was adjusted to 6.8, ultrasonication was performed for 1.5 h, and the supernatant was obtained by centrifugat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com