Preparation method of flexible tensile strain type sensor

A tensile strain and sensor technology, which is applied in the direction of transmitting sensing components and instruments using electric/magnetic devices, can solve problems such as small strain range, and achieve the effects of good product performance, expanded use range and fast response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

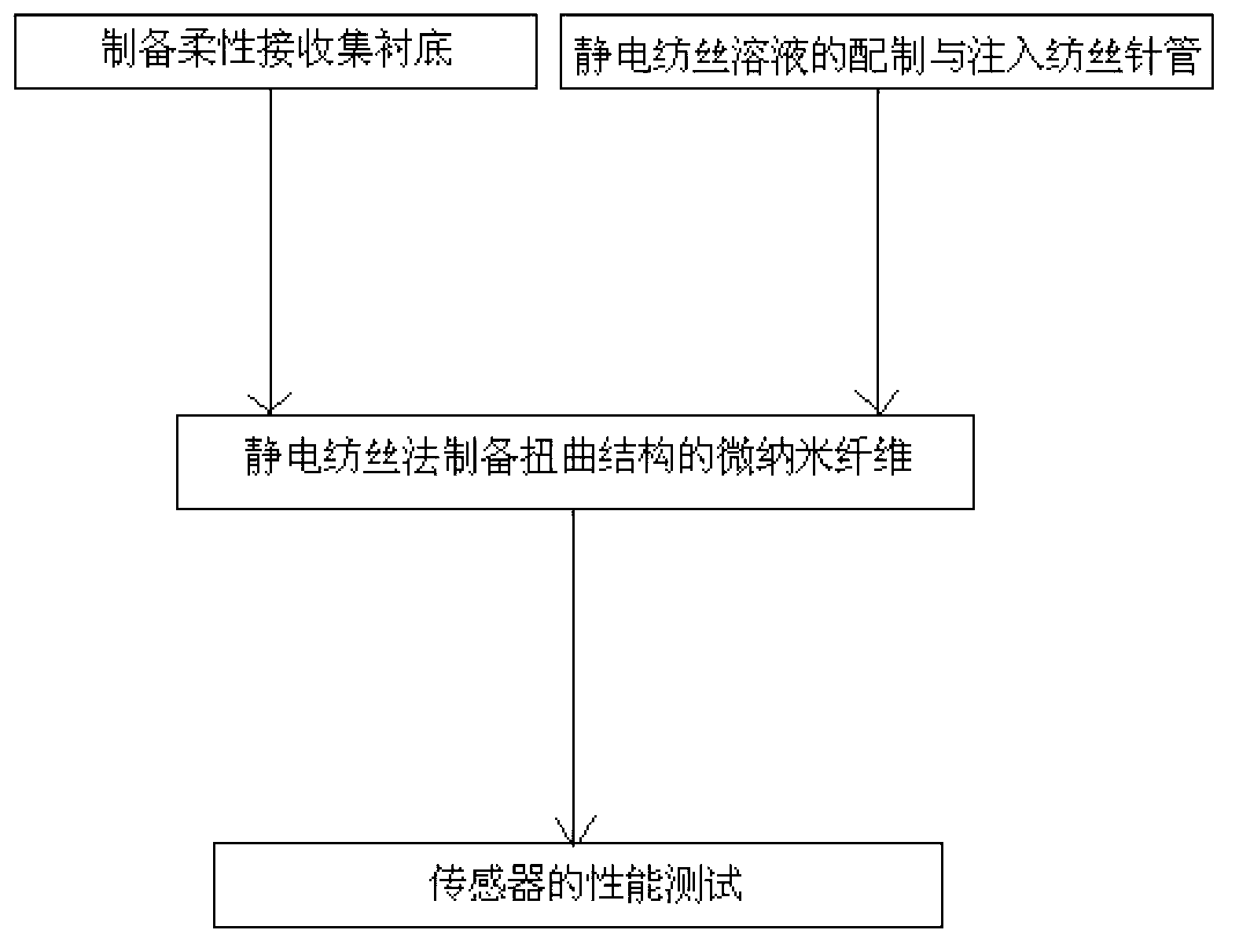

[0016] The specific steps for preparing a flexible stretchable strain sensor in this example include preparation of a flexible receiving substrate, preparation and injection of an electrospinning solution into a spinning needle, preparation of twisted micro-nano fibers by electrospinning, and performance testing of the sensor Four steps:

[0017] (1) Preparation of a flexible receiver substrate: fix an elastic polymer material substrate on a glass sheet, then place it on an aluminum foil connected to the negative electrode of the power supply as a flexible receiver substrate, and use a clean, dry paper Cover it, and its polymer material substrate includes a rubber sheet and a plastic sheet, and its geometric dimensions are length × width × thickness = 3-5 × 2-3 × 0.1-0.5cm, the present embodiment chooses 3.5cm × 2cm × 0.1 cm thin slices of balloon skin;

[0018] (2) Preparation and injection of electrospinning solution into spinning needle: the selected spinning solution is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com