Neural electrode interface modification material as well as neural electrode and preparation method of neural electrode

A technology for electrode interface and modified materials, which is applied in electrodes, internal electrodes, medical science, etc., can solve the problems of neuron damage, affect the performance of nerve electrodes, and fail to meet long-term implantation, so as to improve biocompatibility and improve durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

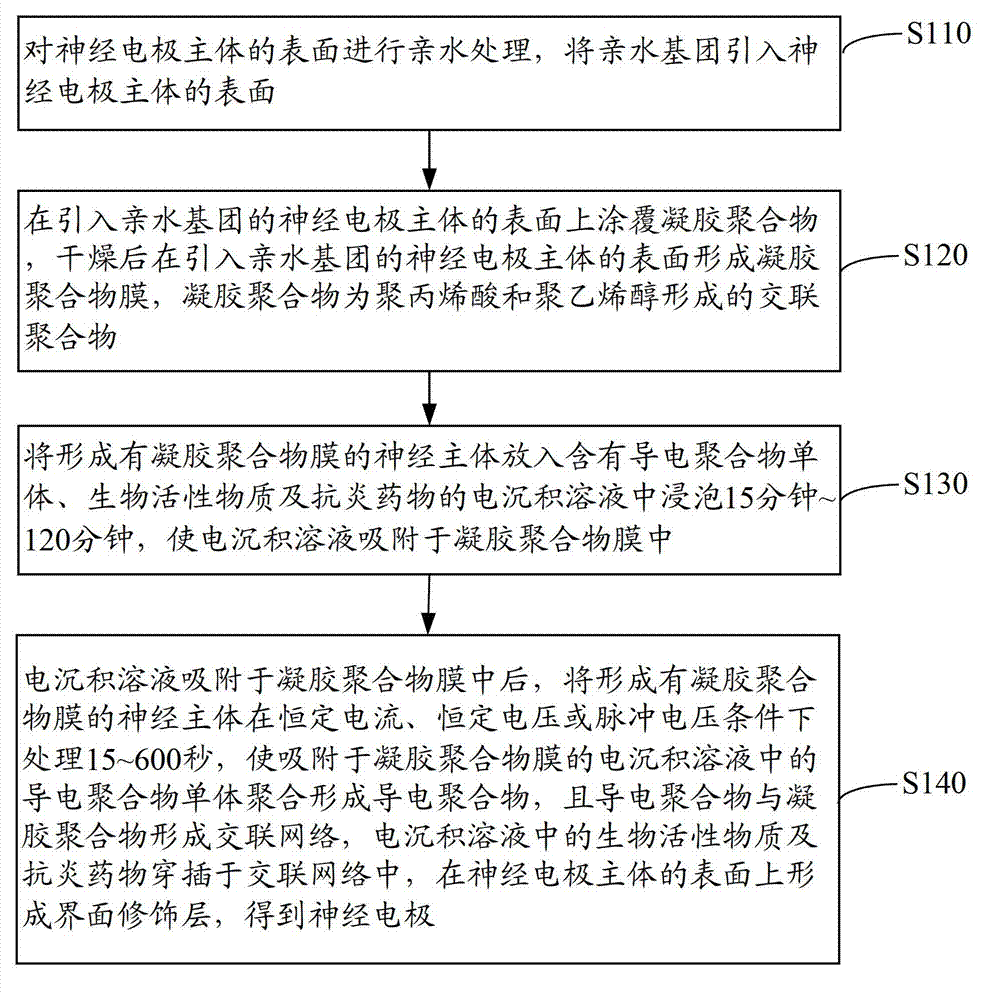

[0049] see figure 2 , the preparation method of the neural electrode of an embodiment, comprises the following steps:

[0050] Step S110: performing hydrophilic treatment on the surface of the nerve electrode body, and introducing hydrophilic groups into the surface of the nerve electrode body.

[0051] The non-functional area of the nerve electrode body is formed of materials such as silicone rubber, polyimide, or silicon dioxide. Due to the strong hydrophobicity of silicone rubber, polyimide and other materials, in order to subsequently form an interface modification layer closely combined with the nerve electrode body, the surface of the nerve body is firstly treated with hydrophilicity to improve the hydrophilicity of the nerve body surface.

[0052] In this embodiment, the nerve electrode body is subjected to plasma treatment for 30 to 120 seconds under glow discharge conditions, and hydrophilic groups are introduced into the surface of the nerve electrode body, and t...

Embodiment 1

[0076] Preparation of neural electrodes

[0077] 1. The nerve electrode body is subjected to plasma treatment under glow discharge conditions for 30 seconds, and hydrophilic groups are introduced into the surface of the nerve electrode body, and the hydrophilic groups are distributed on the surface of the non-functional area and the functional area of the nerve electrode body;

[0078] 2. Mix acrylic acid monomer and polyvinyl alcohol aqueous solution (the mass fraction of polyvinyl alcohol is 2%), wherein the molar ratio of acrylic acid monomer and polyvinyl alcohol repeating segment is 3:2. Acrylic acid is polymerized in the mixed solution to form polyacrylic acid, and forms polyacrylic acid-polyvinyl alcohol cross-linked polymer with polyvinyl alcohol to obtain a water-containing gel polymer, wherein the mass ratio of polyacrylic acid to polyvinyl alcohol is 27: 11. Coating the above-mentioned hydrogel polymer on the surface of the nerve electrode body with hydrophilic g...

Embodiment 2

[0087] Preparation of neural electrodes

[0088] 1. The nerve electrode body is subjected to plasma treatment under glow discharge conditions for 120 seconds, and hydrophilic groups are introduced into the surface of the nerve electrode body, and the hydrophilic groups are distributed on the surface of the non-functional area and the functional area of the nerve electrode body;

[0089] 2. Mix acrylic acid monomer and polyvinyl alcohol aqueous solution (the mass fraction of polyvinyl alcohol is 5%), wherein the molar ratio of acrylic acid monomer and polyvinyl alcohol repeating segment is 2:3. Acrylic acid is polymerized in the mixed solution to form polyacrylic acid, and forms polyacrylic acid-polyvinyl alcohol cross-linked polymer with polyvinyl alcohol to obtain a water-containing gel polymer, wherein the mass ratio of polyacrylic acid to polyvinyl alcohol is 12: 11. Coating the above-mentioned hydrogel polymer on the surface of the nerve electrode body with hydrophilic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com