A reduction method for iron-based catalysts in slurry-bed Fischer-Tropsch synthesis

An iron-based catalyst and Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, catalyst activation/preparation, preparation of liquid hydrocarbon mixtures, etc., can solve problems affecting the normal operation of the reactor, excessive carbon deposition on the catalyst, and affecting catalyst activity , to achieve the effect of strong wear resistance, less carbon deposition on the catalyst, and less carburization of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

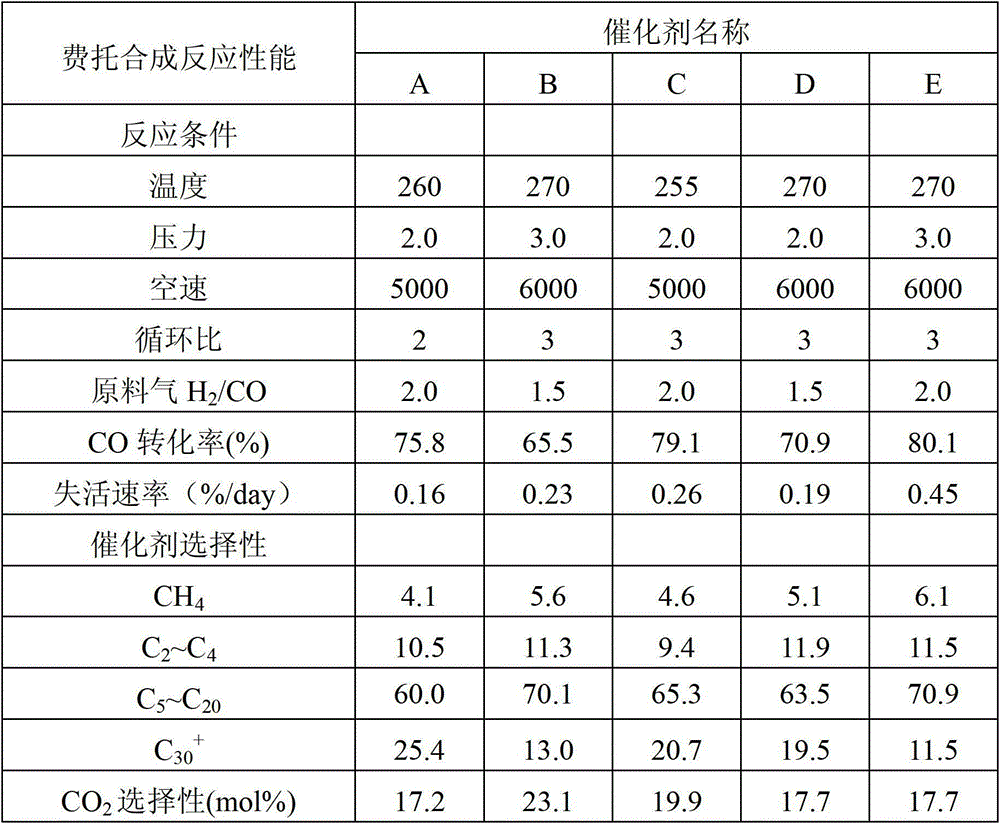

Embodiment 1

[0034] Add 10g of Fischer-Tropsch synthesis iron-based catalyst and 400g of liquid paraffin with an initial boiling point greater than 280°C into the slurry bed reactor, and the catalyst composition is 100Fe / 3Cu / 1K / 20SiO 2 (for mass ratio). The reduction reactor was filled with N 2 Inject C after gas purging 2 h 4 , adjust the reactor pressure to 3.0MPa, and the space velocity to 1000h -1 , the circulation ratio is 8, and the reactor is raised from room temperature to 270°C with a temperature increase rate of 10°C / h for 24h to obtain the reduced iron-based catalyst, denoted as A.

[0035] After the reduction is completed, switch the reduction condition to the reaction condition to carry out the Fischer-Tropsch synthesis reaction. The reaction conditions are: the reaction temperature is 260°C, the pressure is 3.0MPa, and the raw material gas is H 2 / CO=2.0 (molar ratio), the space velocity is 5000h -1 , and the cycle ratio is 2.0.

[0036] The performance evaluation resu...

Embodiment 2

[0038] Add 15g of Fischer-Tropsch synthesis iron-based catalyst and 450g of liquid paraffin with an initial boiling point greater than 280°C into the slurry bed reduction reactor, and the catalyst composition is 100Fe / 5Mn / 2K / 20SiO 2 (for mass ratio). The reduction reactor was filled with N 2 H was introduced after gas purging 2 / C 2 h 4 (Molar ratio is 30:1) mixed gas, adjust the reactor pressure to 3.0MPa, and the space velocity to 2000h -1 , the reactor was raised from room temperature to 250°C with a temperature increase rate of 10°C / h and then kept at a constant temperature for 48h to obtain the reduced iron-based catalyst, denoted as B. There is no exhaust gas circulation during the reduction process.

[0039] After the reduction is completed, switch the reduction condition to the reaction condition to carry out the Fischer-Tropsch synthesis reaction. The reaction conditions are: the reaction temperature is 270°C, the pressure is 3.0MPa, and the feed gas is H 2 / CO...

Embodiment 3

[0042] Add 8g of Fischer-Tropsch synthesis iron-based catalyst and 400g of liquid paraffin with an initial boiling point greater than 320°C into the slurry bed reduction reactor, and the catalyst composition is 100Fe / 5Mo / 6K / 15SiO 2 (for mass ratio). The reduction reactor was filled with N 2 H was introduced after gas purging 2 / CH 4 (molar ratio is 5:1) mixed gas, adjust the reactor pressure to 1.5MPa, and the space velocity to 3000h -1 , the circulation ratio is 5, and the reactor is raised from room temperature to 280° C. with a temperature increase rate of 5° C. / h for 36 hours to obtain the reduced iron-based catalyst, denoted as C.

[0043] After the reduction is completed, switch the reduction condition to the reaction condition to carry out the Fischer-Tropsch synthesis reaction. Reaction condition is: reaction temperature 255 ℃, pressure is 3.0MPa, raw material gas is H 2 / CO=2.0 (molar ratio), the space velocity is 5000h -1 , and the cycle ratio is 3.0.

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com