Industrial abrasive belt based on substrate formed by compounding knitted fabric or woven fabric with plastic film

A technology of plastic film and woven cloth, applied in the direction of abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of high manufacturing cost, reduced production and use cost, poor mechanical properties, etc., to reduce environmental pollution and improve mechanical properties performance, cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and embodiments:

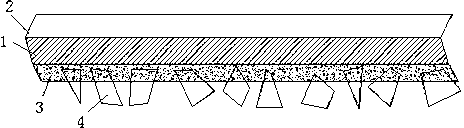

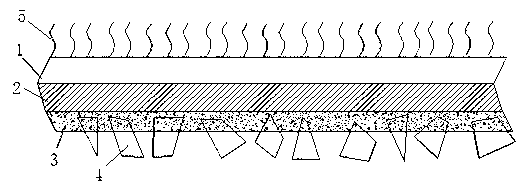

[0017] Such as figure 1 with figure 2 The industrial abrasive belt based on the composite substrate of knitted fabric or woven fabric and plastic film of the present invention is shown, including knitted fabric or woven fabric and plastic film bonded to it. On the sides of the film away from each other, one of the sides is coated with primer, and an abrasive layer is formed by electrostatic sand planting on the side coated with the primer. The knitted fabric or woven fabric is impregnated with glue or scratched Treated; when one side of the plastic film is coated with primer, one side of the knitted fabric or woven fabric can be processed by fleece to form a fleece surface, and it can also be used on the knitted fabric or woven fabric After fleece on one side, it is attached to the plastic film, and the fleece can be used on the machine after the fleece is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com