Pneumatic heating and quick warming process and equipment for same

A pneumatic heating and fast technology, which is applied in the fields of petroleum industry, cracking, hydrocarbon cracking and hydrocarbon production, etc., can solve the problems of increased flow resistance, reduced flow cross-sectional area, insufficient furnace tube reaction temperature, etc., and achieve the effect of avoiding coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

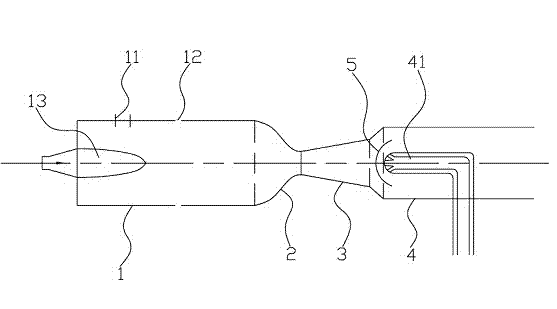

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0025] A pneumatic heating rapid heating process provided in an embodiment of the present invention includes the following steps:

[0026] (1) Pass the high-speed fluid and the fluid to be heated that flow in opposite directions in the same pipeline;

[0027] (2) Accelerate the high-speed fluid to the speed of sound or supersonic before the high-speed fluid meets the fluid to be heated;

[0028] (3) When the high-speed fluid meets the fluid to be heated, a shock wave is generated. After the shock wave is generated, the static temperature of the high-speed fluid rises rapidly, and then quickly mixes with the fluid to be heated to rapidly increase the temperature of the fluid to be heated.

[0029] In this embodiment, the high-speed fluid is preferably water vapor, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mach number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com