Method for improving light-perspiration color fastness of reactive brilliant red dyed fabric

A reactive bright red, color fastness technology, used in plant fibers, textiles and papermaking, fiber processing and other directions, can solve the problems of low fastness to ultraviolet absorbers, affecting the feel and appearance of textiles, and poor fastness to sunlight. , to permanently improve light fastness, good light fastness to perspiration and sunlight, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

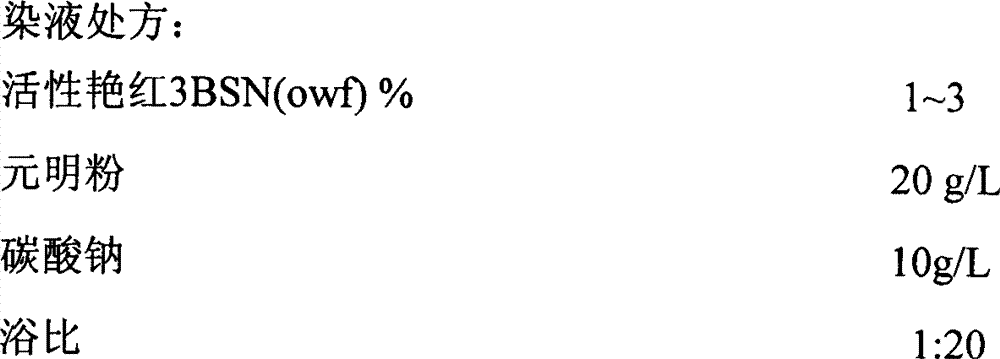

[0030] Example 1: Dyeing of Cotton Fabrics and Measurement of Color Fastness to Light and Perspiration

[0031] (1) Dyeing: cotton fabric is put into the aqueous solution containing 1% (owf), 2% (owf), 3% (owf) of reactive brilliant red 3BSN respectively, bath ratio 1: 20, after being heated up to 40 ℃, Add 20g / L Yuanming powder and 5g / L sodium carbonate, react for 30min, then raise the temperature to 80°C, then add 5g / L Na 2 CO 3 , continue to react for 60 minutes, take out the fabric, wash it with water, and dry it.

[0032] (2) The above-mentioned cotton fabric dyed with reactive brilliant red 3BSN was treated in acidic sweat solution for 30 minutes to evenly soak into the solution, and then the fabric was irradiated with German ATLAS-150S light fastness meter for 100 hours. Use the Macbeth Color-eye 7000A color measuring instrument to evaluate the degree of fading of the fabric as 2-4 grades (1% owf), 3-4 grades (2% owf) and 4 grades (3% owf); use the gray scale to evalu...

Embodiment 2

[0034] Example 2: Determination of Dyeing and Light / Sweat Color Fastness of Cotton Fabrics after UV Absorber Finishing

[0035] (1) Soak the cotton fabric at 40°C in a pH=9 sodium carbonate solution with a bath ratio of 1:30 for 30 minutes, then soak it twice and roll it twice (the excess rate is 90%), dry it at 50°C, and dry it at 60°C Cotton fabric is soaked in the N,N-dimethylformamide finishing solution that is that the bath ratio is 1:30 containing 2% (owf) ultraviolet absorber UV-DTHM to the fabric again after 30min, two dipping two rolling (rolling) The remaining rate is 85%), steamed at 100°C for 60min. The cotton fabric after finishing is put into respectively in the aqueous solution containing the reactive brilliant red 3BSN of 1% (owf), 2% (owf), 3% (owf), after warming up to 40 ℃, add 20g / L Yuanming powder and 5g / L sodium carbonate, react for 30min, then raise the temperature to 80°C, add 5g / L Na 2 CO 3 , continue to react for 60 minutes, take out the fabric, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com