Pipeline leakage automatic blocking valve

A pipeline leakage and automatic technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of unsatisfactory plugging effect, complex system structure, long assembly time, etc., and achieve ideal plugging effect and high safety , the effect of short assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

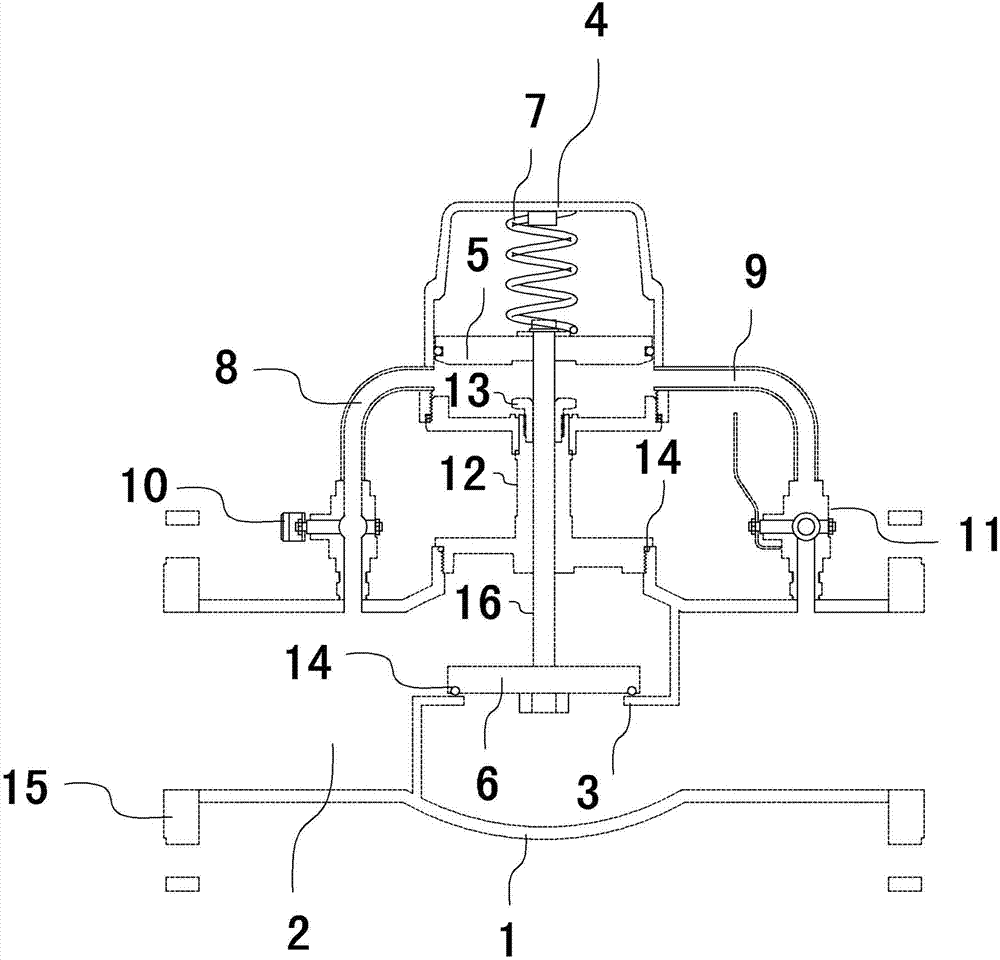

[0013] As shown in the figure, the pipeline leakage automatic sealing valve includes a valve body 1; the valve body 1 includes a main channel 2 and an automatic shut-off mechanism; the main channel 2 is fixed with a shut-off port 3; the automatic shut-off The mechanism includes a cylinder 4, a valve 6 and a piston 5 placed in the cylinder 4; the piston 5 is in motion with the inner wall of the cylinder 4, and its geometric center is fixedly connected to the valve 6 through a connecting rod 16; the top of the piston 5 is connected to the cylinder A thrust spring 7 is fixed between the tops of 4; the working surface of the valve 6 corresponds to the shut-off port 3 to ensure the opening and closing of the main channel 2; the first drainage is fixed on both sides of the cylinder 4 Branch 8 and second drainage branch 9; the two ports of the first drainage branch 8 and the second drainage branch 9 communicate with the inner cavity of the main channel 2 and the bottom area of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com