Automated test device for simulating ocean level fluctuation zone and wave splash zone

A technology of water level fluctuation area and test device, which is applied in the field of port and offshore engineering, can solve the problems of heavy labor, seldom used, cumbersome operation process, etc., to reduce the intensity of manual labor, meet the long-term use requirements, and improve test efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

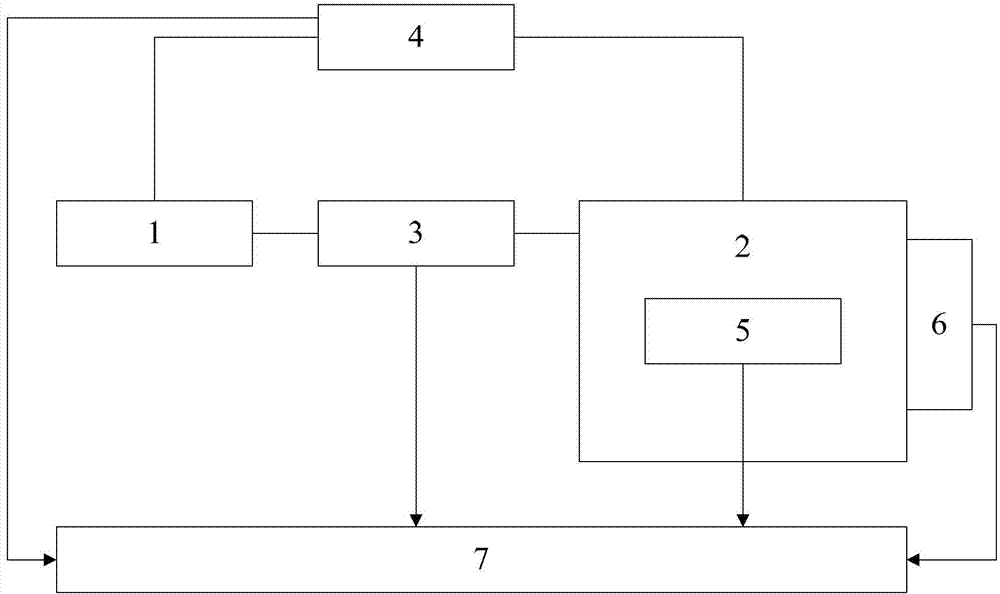

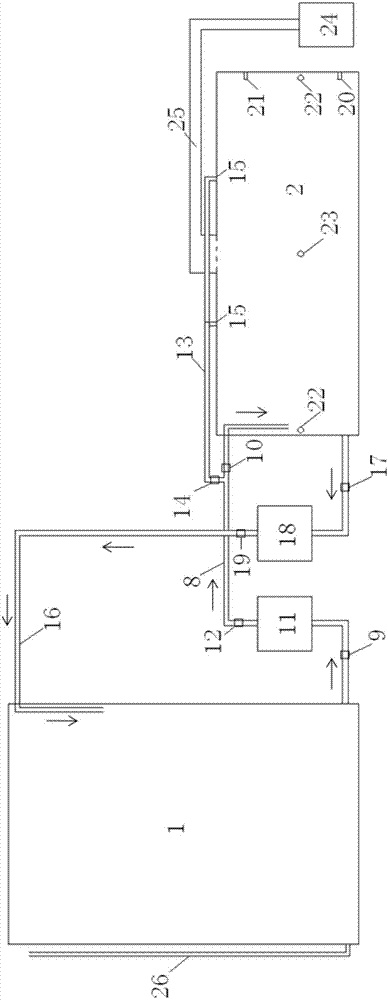

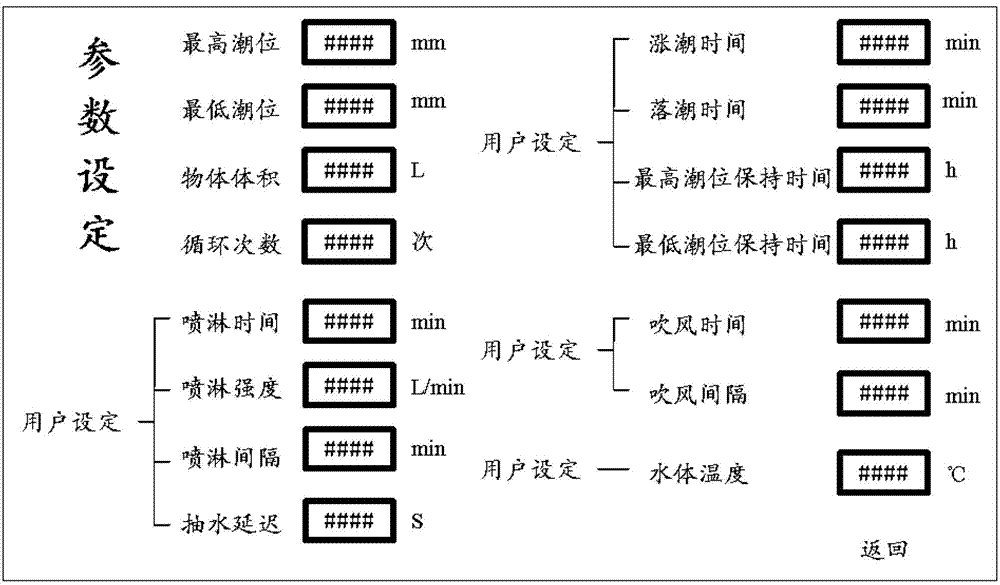

[0043] In order to effectively simulate the environment of the actual ocean water level fluctuation area and the splash area, reduce the labor intensity, simplify the operation process, and improve the seawater utilization rate and work efficiency, the embodiment of the present invention proposes a simulation of the ocean water level fluctuation area and the wave splash area. For automated test setups for splash zones, see figure 1 , including: a water storage tank 1, the water storage tank 1 is connected with a corrosion water tank 2 through a tidal control system 3,

[0044] A splash control system 4 is connected between the water storage tank 1 and the corrosion tank 2, a seawater temperature control system 5 is installed in the corrosion tank 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com